ABS IMPROVED

Better braking through better electronics

KEVIN CAMERON

The day had to arrive when an ABS system would equal or exceed the braking performance of a skilled motorcyclist, but it’s been a long time coming. As noted in the main story, it took Don Canet four tries on a conventional bike to achieve a shorter stopping distance than with C-ABS, now optional on the CBR600RR and CBR1000RR. As he remarks, when a real emergency arises, you don’t get multiple tries.

Early ABS of the 1980s was more a proof-of-concept than a challenge to human skill. Such systems operated in a series of

clearly visible lock/unlock cycles, causing suspension to nod. Back through the brake system came very obvious pulsation that told the rider “ABS in operation!” Overtime, the cycle frequency has been increased and performance improved, but ABS tended to remain more a curiosity for the funny-hat people than a serious challenge to real skill.

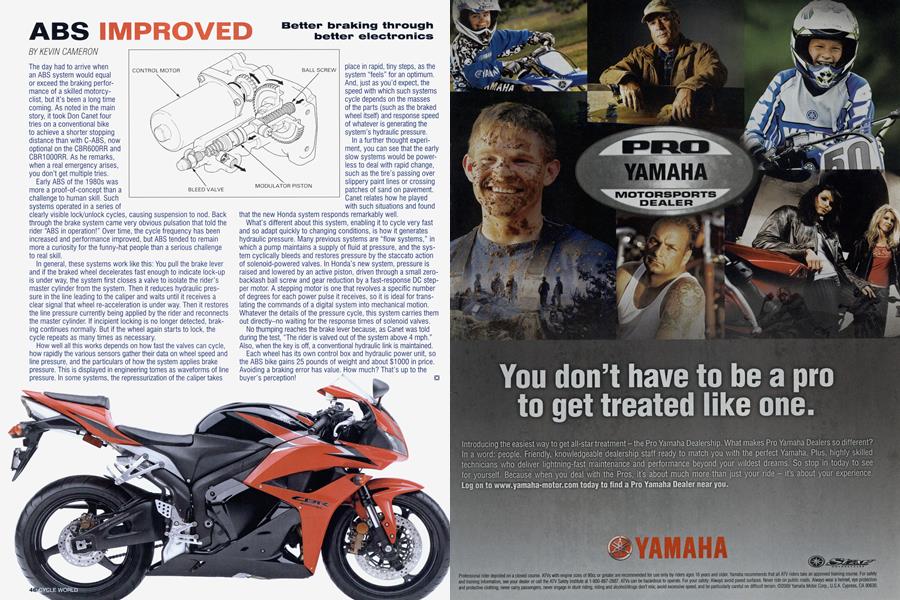

In general, these systems work like this: You pull the brake lever and if the braked wheel decelerates fast enough to indicate lock-up is under way, the system first closes a valve to isolate the rider’s master cylinder from the system. Then it reduces hydraulic pressure in the line leading to the caliper and waits until it receives a clear signal that wheel re-acceleration is under way. Then it restores the line pressure currently being applied by the rider and reconnects the master cylinder. If incipient locking is no longer detected, braking continues normally. But if the wheel again starts to lock, the cycle repeats as many times as necessary.

How well all this works depends on how fast the valves can cycle, how rapidly the various sensors gather their data on wheel speed and line pressure, and the particulars of how the system applies brake pressure. This is displayed in engineering tomes as waveforms of line pressure. In some systems, the repressurization of the caliper takes place in rapid, tiny steps, as the system “feels” for an optimum. And, just as you’d expect, the speed with which such systems cycle depends on the masses of the parts (such as the braked wheel itself) and response speed of whatever is generating the system’s hydraulic pressure.

In a further thought experiment, you can see that the early slow systems would be powerless to deal with rapid change, such as the tire’s passing over slippery paint lines or crossing patches of sand on pavement. Canet relates how he played with such situations and found

that the new Honda system responds remarkably well.

What’s different about this system, enabling it to cycle very fast and so adapt quickly to changing conditions, is how it generates hydraulic pressure. Many previous systems are “flow systems,” in which a pump maintains a supply of fluid at pressure, and the system cyclically bleeds and restores pressure by the staccato action of solenoid-powered valves. In Honda’s new system, pressure is raised and lowered by an active piston, driven through a small zerobacklash ball screw and gear reduction by a fast-response DC stepper motor. A stepping motor is one that revolves a specific number of degrees for each power pulse it receives, so it is ideal for translating the commands of a digital system into mechanical motion. Whatever the details of the pressure cycle, this system carries them out directly-no waiting for the response times of solenoid valves.

No thumping reaches the brake lever because, as Canet was told during the test, “The rider is valved out of the system above 4 mph.” Also, when the key is off, a conventional hydraulic link is maintained.

Each wheel has its own control box and hydraulic power unit, so the ABS bike gains 25 pounds of weight and about $1000 in price. Avoiding a braking error has value. How much? That’s up to the buyer’s perception! / *