CLUTCH CONUNDRUM

Kevin Cameron

SINCE THE 1970S, IT’S been normal for riders of two-stroke Grand Prix bikes to brake to the point of rear-wheel lift. Although this is an unstable condition (the bike would love to switch ends, but the rider keeps its mass centered behind the front tire), down-shifting does not upset it because two-strokes have very low friction and, therefore, little engine braking.

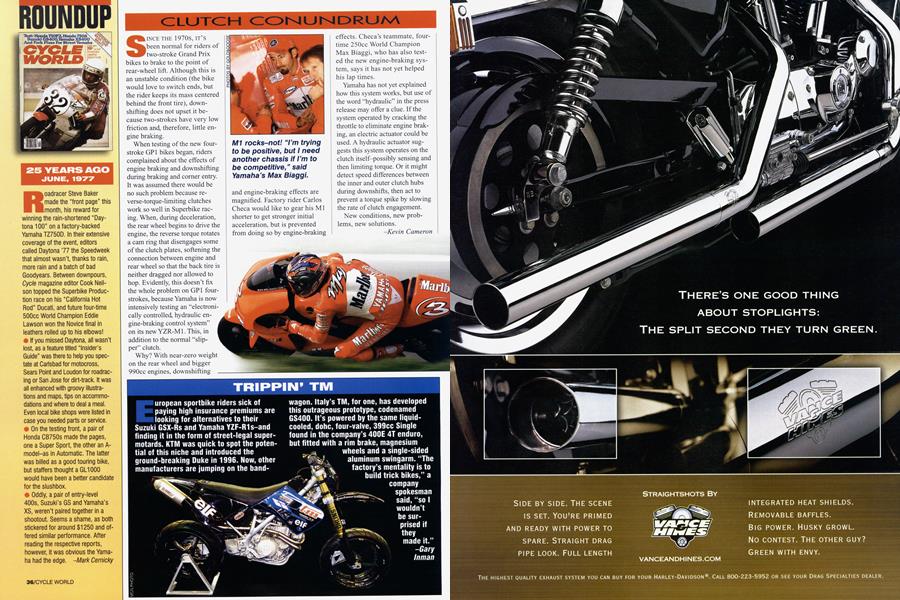

When testing of the new fourstroke GP1 bikes began, riders complained about the effects of engine braking and downshifting during braking and comer entry. It was assumed there would be no such problem because reverse-torque-limiting clutches work so well in Superbike racing. When, during deceleration, the rear wheel begins to drive the engine, the reverse torque rotates a cam ring that disengages some of the clutch plates, softening the connection between engine and rear wheel so that the back tire is neither dragged nor allowed to hop. Evidently, this doesn’t fix the whole problem on GP 1 fourstrokes, because Yamaha is now intensively testing an “electroni cally controlled, hydraulic engine-braking control system” on its new YZR-M1. This, in addition to the normal “slipper” clutch.

Why? With near-zero weight on the rear wheel and bigger 990cc engines, downshifting and engine-braking effects are magnified. Factory rider Carlos Checa would like to gear his Ml shorter to get stronger initial acceleration, but is prevented from doing so by engine-braking effects. Checa’s teammate, fourtime 250cc World Champion Max Biaggi, who has also tested the new engine-braking system, says it has not yet helped his lap times.

Yamaha has not yet explained how this system works, but use of the word “hydraulic” in the press release may offer a clue. If the system operated by cracking the throttle to eliminate engine braking, an electric actuator could be used. A hydraulic actuator suggests this system operates on the clutch itself-possibly sensing and then limiting torque. Or it might detect speed differences between the inner and outer clutch hubs during downshifts, then act to prevent a torque spike by slowing the rate of clutch engagement.

New conditions, new problems, new solutions.

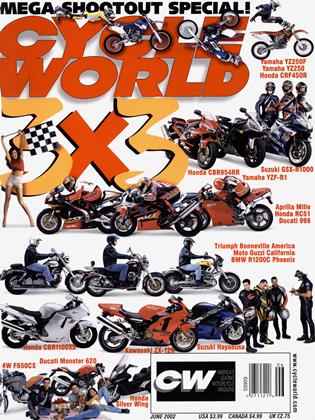

View Full Issue

View Full Issue

More From This Issue

-

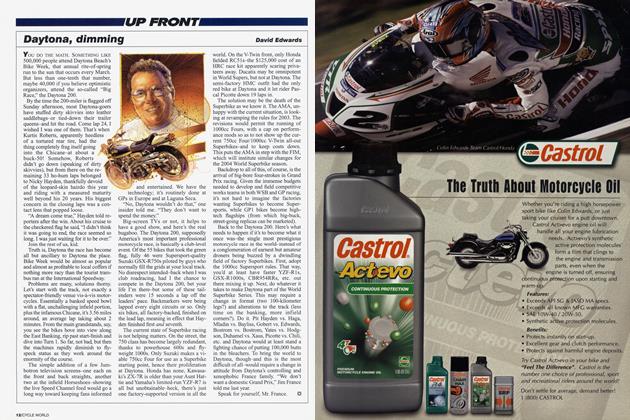

Up Front

Up FrontDaytona, Dimming

June 2002 By David Edwards -

Leanings

LeaningsA Steam-Shovel And A Piece of Earth

June 2002 By Peter Egan -

TDC

TDCAll In A Row

June 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

June 2002 -

Roundup

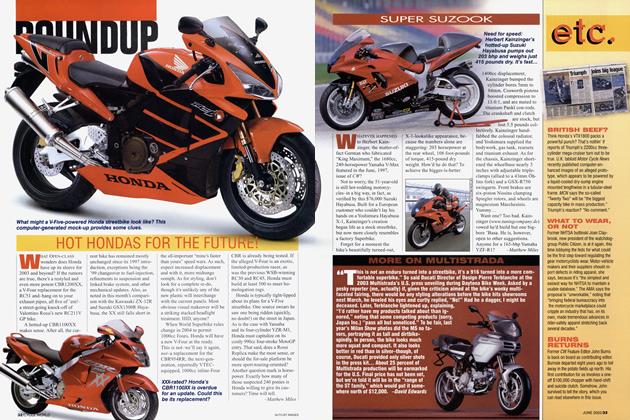

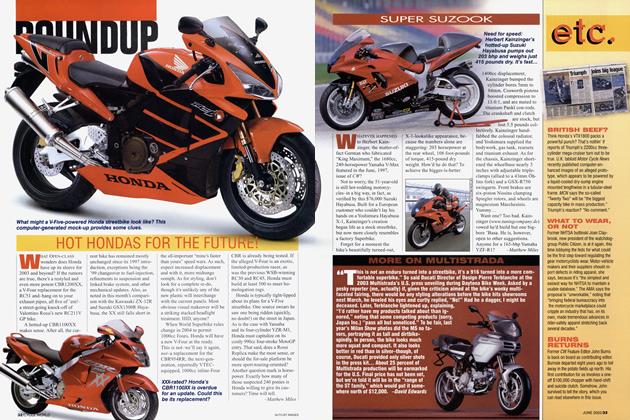

RoundupHot Hondas For the Future!

June 2002 By Matthew Miles -

Roundup

RoundupSuper Suzook

June 2002 By Matthew Miles