Short skirts

TDC

Kevin Cameron

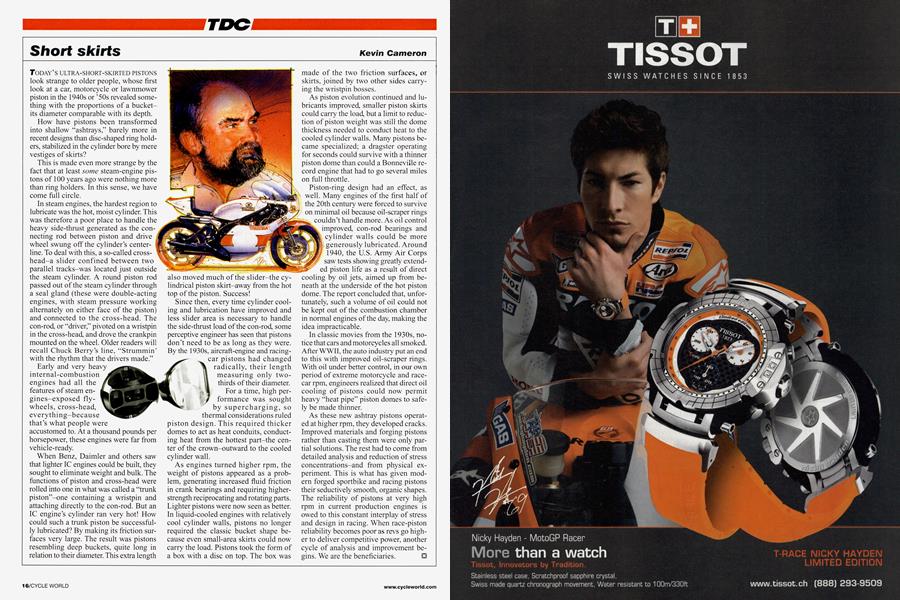

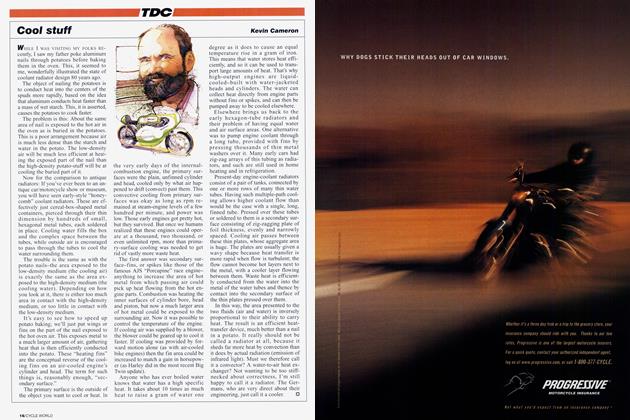

TODAY’S ULTRA-SHORT-SKIRTED PISTONS look strange to older people, whose first look at a car, motorcycle or lawnmower piston in the 1940s or ’50s revealed something with the proportions of a bucketits diameter comparable with its depth.

How have pistons been transformed into shallow “ashtrays,” barely more in recent designs than disc-shaped ring holders, stabilized in the cylinder bore by mere vestiges of skirts?

This is made even more strange by the fact that at least some steam-engine pistons of 100 years ago were nothing more than ring holders. In this sense, we have come full circle.

In steam engines, the hardest region to lubricate was the hot, moist cylinder. This was therefore a poor place to handle the heavy side-thrust generated as the connecting rod between piston and drive wheel swung off the cylinder’s centerline. To deal with this, a so-called crosshead-a slider confined between two parallel tracks-was located just outside the steam cylinder. A round piston rod passed out of the steam cylinder through a seal gland (these were double-acting engines, with steam pressure working alternately on either face of the piston) and connected to the cross-head. The con-rod, or “driver,” pivoted on a wristpin in the cross-head, and drove the crankpin mounted on the wheel. Older readers will recall Chuck Berry’s line, “Strummin’ with the rhythm that the drivers made.”

Early and very heavy internal-combustion engines had all the features of steam engines-exposed flywheels, cross-head, everything-because that’s what people were accustomed to. At a thousand pounds per horsepower, these engines were far from vehicle-ready.

When Benz, Daimler and others saw that lighter IC engines could be built, they sought to eliminate weight and bulk. The functions of piston and cross-head were rolled into one in what was called a “trunk piston”-one containing a wristpin and attaching directly to the con-rod. But an IC engine’s cylinder ran very hot! How could such a trunk piston be successfully lubricated? By making its friction surfaces very large. The result was pistons resembling deep buckets, quite long in relation to their diameter. This extra length also moved much of the slider-the cylindrical piston skirt-away from the hot top of the piston. Success!

Since then, every time cylinder cooling and lubrication have improved and less slider area is necessary to handle the side-thrust load of the con-rod, some perceptive engineer has seen that pistons don’t need to be as long as they were. By the 1930s, aircraft-engine and racingcar pistons had changed radically, their length measuring only twothirds of their diameter.

For a time, high performance was sought by supercharging, so thermal considerations ruled piston design. This required thicker domes to act as heat conduits, conducting heat from the hottest part-the center of the crown-outward to the cooled cylinder wall.

As engines turned higher rpm, the weight of pistons appeared as a problem, generating increased fluid friction in crank bearings and requiring higherstrength reciprocating and rotating parts. Lighter pistons were now seen as better. In liquid-cooled engines with relatively cool cylinder walls, pistons no longer required the classic bucket shape because even small-area skirts could now carry the load. Pistons took the form of a box with a disc on top. The box was

made of the two friction surfaces, or skirts, joined by two other sides carrying the wristpin bosses.

As piston evolution continued and lubricants improved, smaller piston skirts could carry the load, but a limit to reduction of piston weight was still the dome thickness needed to conduct heat to the cooled cylinder walls. Many pistons became specialized; a dragster operating for seconds could survive with a thinner piston dome than could a Bonneville record engine that had to go several miles on full throttle.

Piston-ring design had an effect, as well. Many engines of the first half of the 20th century were forced to survive on minimal oil because oil-scraper rings couldn’t handle more. As oil control improved, con-rod bearings and cylinder walls could be more generously lubricated. Around 1940, the U.S. Army Air Corps saw tests showing greatly extended piston life as a result of direct cooling by oil jets, aimed up from beneath at the underside of the hot piston dome. The report concluded that, unfortunately, such a volume of oil could not be kept out of the combustion chamber in normal engines of the day, making the idea impracticable.

In classic movies from the 1930s, notice that cars and motorcycles all smoked. After WWII, the auto industry put an end to this with improved oil-scraper rings. With oil under better control, in our own period of extreme motorcycle and racecar rpm, engineers realized that direct oil cooling of pistons could now permit heavy “heat pipe” piston domes to safely be made thinner.

As these new ashtray pistons operated at higher rpm, they developed cracks. Improved materials and forging pistons rather than casting them were only partial solutions. The rest had to come from detailed analysis and reduction of stress concentrations-and from physical experiment. This is what has given modern forged sportbike and racing pistons their seductively smooth, organic shapes. The reliability of pistons at very high rpm in current production engines is owed to this constant interplay of stress and design in racing. When race-piston reliability becomes poor as revs go higher to deliver competitive power, another cycle of analysis and improvement begins. We are the beneficiaries. □