SERVICE

PAUL DEAN

Confusion over overrun

Q Could you please explain the word “overrun”? I read many reports on new-model motorcycles in which the writers use that word in different ways, and I really don’t know what they are talking about.

John Eannetta Hayward, California

A Overrun describes what occurs when you close the throttle any time the vehicle is in gear and moving, which causes the rear wheel to drive the engine instead of the engine driving the rear wheel. Overrun takes place when you are slowing down, coming to a complete stop or riding down a hill steep enough to allow the bike to maintain or increase its speed without any throttle opening. This same condition is also often called “trailing throttle.”

Which way is up?

QI have a question about progressively wound fork springs. A highly respected suspension expert says that springs of this type should be inserted in their fork tubes with the closely wound coils on top to reduce unsprung mass, while the official factory service manual for my bike says that those coils should be placed at the bottom-although the manual does not explain why. I happen to agree with the suspension expert, but your opinion on this matter would be greatly appreciated. Ted Williamson

Posted on www.cycleworld.com

A You didn’t reveal any specificssuch as the name of the suspension expert or the make and model of your motorcycle-so I can’t be very specific in my reply. But I can tell you that

for at least 95 percent of riders at least 95 percent of the time, the orientation of the fork springs is of little consequence. Yes, inserting the springs with the closely wound coils at the top will reduce unsprung weight somewhat, but not enough for anyone but the most sensitive pro racers or testers to detect under controlled conditions. On most progressive springs, the difference in weight between one end of the coils and the other is pretty small. Besides, not all of a suspension spring is unsprung weight; as far as any given coil in the spring is concerned, only the coils below it are unsprung, while all those above it are sprung.

Why does your shop manual recommend installing the springs with the closely wound coils at the bottom? My guess-and it is just that, a guess-is that it allows marginally better fork behavior on that particular bike. When a suspension hits a sharp, abrupt bump, the spring doesn’t initially compress evenly from both ends; a shock wave travels up through the spring from the bottom, which is where the impact took place. Placing the closely wound (softer) coils at the bottom may give them the ability to absorb that initial impact more effectively than if they were at the top. That manufacturer’s R&D testing could have shown that this spring orientation offsets any advantage that could be gained from a reduction in unsprung weight.

Thermal expansion

QI recently bought a 2006 Yamaha YZF-R6 with 10,000 miles on it. The engine didn’t want to rev out when it was cold but would run perfectly once warmed. I did a leakdown test and saw that every cylinder was leaking through the exhaust valve. I checked the valve clearances and found that all but one of the exhaust valves were “tight,” with no clearance at all. So I did a complete valve adjustment and got all the valves within the specified clearances. The bike now runs perfectly hot or cold.

My question is, doesn’t heat make metal expand? I would think that the valve clearances would have been on the loose side when cold because the bike runs better when warm. Also, is it true that valves adjusted with shimand-bucket tappets always get tighter and screw-and-locknut types always get looser? Johnny Voong

Posted on www.cycleworld.com

A Metal does expand as it gets hotter, but not all metals expand at the same rate. The cylinder head on your R6 is made of aluminum, while the valves are a titanium alloy, and aluminum has an expansion rate about twice that of titanium-or, for that matter, of steel. As the cylinder head expands, the cams are shifted farther away from the bucket tappets and valves, both of which expand at a lesser rate. Thus, the valve clearance increases.

This is not necessarily the case on all engines, however; on others, depending upon the design and material content of the head and valves, the clearance may be reduced when hot. As far as your second question is concerned, shimThus, the big difference //. between 3 percent and 33 percent makes it appear unlikely that different oil is responsible for all of your mileage improvement. Was the engine fully broken-in on the earlier oil? Friction falls somewhat during break-in, which is why I ask. Air-cooled engines run lower oil temperatures in the winter months because oil viscosity-the source of most friction-rises as temperature falls. Also, with modern low-vapor-pressure fuels, less than 100 percent of the fuel may actually form combustible vapor in the colder months. and-bucket tappets do usually get tighter over time, just as screw-and-locknut de signs usually loosen. But not always. On both types, clearances gradually tighten if the constant impact of valve closures hammers away at the valves and their seats. The seat widens and the valve face becomes slightly indented, so the top of the valve stem protrudes farther above the valve guide, reducing the clearance. Also, screw-and-locknut adjusters have two separate contact areas (cam-to-follower and follower-to-valve-stem) in which two surfaces “wipe” against one another to create potential wear, but shim-and-bucket types have just one. This tends to make the screw-type adjusters gain clearance more often than the shim-and-bucket arrangement.

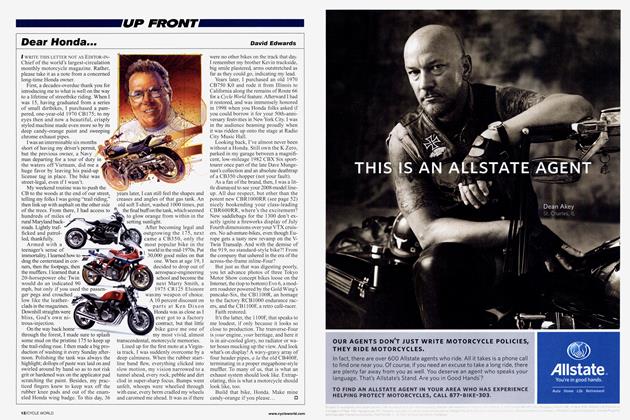

Candid Cameron

QA friend and I have a bet. My experience has been that my mileage has increased when I switched to synthetic oil in two of my Kawasakis, a Vulcan 800 and now a Nomad. The increase has been 2-3 miles per gallon. My friend says only changes in how you use your right wrist affect mileage. Who is right? Jim Lagnese Posted on www.cycleworld.com

A We always have to respect carefully made physical measurements, so if a machine returns fuel mileage that is 2-3 mpg better after the only change being a switch to a different oil, that has to command our attention.

On the other hand, there are certain basics we must also respect. One is that friction loss in typical internal-combustion engines is around 15 percent of delivered power. Because four-stroke engines use about half a pound of fuel for every horsepower they develop for one hour, a typical mileage of 50 mpg would indicate that at highway speeds, we are using 7-8 pounds of fuel per hour, which in turn suggests that the rider is using about 15 hp at that speed. An improvement of 2-3 mpg in fuel consumption would translate to a savings of about 3A of a hp, while the engine’s friction loss at that operating point (15 hp), at 15 percent, would be about 2.25 hp. Saving 3/4 of a hp out of 2.25 is a 33-percent reduction in friction-a lot. When I talk with oil chemists and read the things they write, they speak of modern low-viscosity lubricants cutting friction by maybe 3 percent as compared with the older 10w-30 and 10w-40 oils.

As a result, summer mileage improves.

But some weird things happen in certain engines. At very low rpm, valvetrain friction rises because the cams and tappets are no longer moving fast enough to generate full oil films. That means the load is at least partly supported on solid layers formed from oil additives-and in those cases, friction rises because solid friction is greater than fluid friction. An oil’s ability to form a lubricating fluid film depends only on its viscosity, not upon its chemical composition (petroleum, synthetic, vegetable, etc).

Another point: All oil-makers buy their additive packages, but those packages are supplied at various cost levels. Cheaper ones may not be as effective, long-lasting, heat-resistant, etc. So who knows? When switching oils, a lot of things are changed besides the base oil itself. This includes anti-wear additives and friction modifiers (the so-called “oiliness” additives).

It’s a confusing business, which is why the oil and engine makers spend a lot of money on test apparatus that can repeat tests exactly, and then measure accurately enough to detect very small effects.

My bottom line? Enjoy your improved mileage.

Kevin Cameron

TOOL Time

I t you've never had to deal with boogered-up threads in a sparkplug hole, you've probably not threaded many plugs in and out. Whether of your doing or someone else's, damaged plug threads can be difficult and expensive to repair, often requiring removal of the affected cylinder head. If the threads are only slightly damaged, though, they usually can be cleaned up with one of the many sparkplug rethreading tools, called thread chasers, available at auto parts stores. Only problem is that as those rethreaders trim small amounts of material from the plug hole, the result ant shavings fall down into the cylinder.

But not it you use Mac Tools' (www. mactools.com) Back-Tap Reverse Rethreader, which repairs the threads from the inside out. The culling end of this clever tool is expandable so that when fully contracted, it can be slipped all the way through the plug hole without any meaningful contact with the hole's threads. Before insertion, put a small amount of grease around the last couple of threads at the bottom of the tool. Then, once the Rethreader is fully inserted, turn the thumbscrew atop the tool, which draws a tapered shaft up through the expandable cutting flutes, spreading them out until they are a comfortable fit in the first few threads at the bottom of the hole. Using a box wrench, an open-end wrench or a socket on the hex at the upper end of the Rethreader, turn the tool counterclockwise until it threads itself all the way out of the hole. On its way out, it refreshes the threads from the bottom upward, with the grease on the very tip collecting any shavings that result.

Back-Tap Reverse Rethreaders are available in a $90 3 pack that includes 10mm, 12mm and 14mm sizes; for some unexplained reason, only the 10mm ($34) and 12mm ($37) Rethreaders are sold separately

Asking directions

QWhat is the reason for tread direction designations on tires? I had a ’93 Yamaha Virago and the arrows on its tires indicated to mount the front tire tread backward to the rear tire (tube-type rim, Dunlop 404). But I have seen other Dunlops with the same tread pattern and the arrows show to mount the tread in the same direction. Why is this? Thomas Hardin

Sherman, Texas

A The major forces acting on a bike’s tires do so in opposite directions. In the rear, the tire’s biggest job is to push the motorcycle forward, while the

front tire, via the brake, tries in effect to push it backward. The factors that make tires directional are their construction and their tread pat terns. The materials used in the belt construction are long strips laid around the circumference and overlapped at the ends. If the tire is subjected to the aforementioned forces in the direction opposite that of the wrap, the overlapped material could, to a very small degree, try to unravel. But if the forces act in the same direction as the wrap, the overlapped material would remain undisturbed. So even though the chances of failure are infinitesimal if a tire is mounted in the wrong direction, the tire manufacturers urge you to follow the direction prescribed by the arrows on the sidewalls.

Then there’s the matter of tread pattern. Some treads are designed to channel water out from under the tire more efficiently in one direction than the other in an effort to minimize hydroplaning, while other patterns are unidirectional. If they are directional, the manufacturer may recommend mounting the tires with the pattern facing one way on the front, for better wet-weather braking, and the other way on the rear, for the best wet-road acceleration. The tread can, however, be laid over the carcass in either direction; if the manufacturer so chooses, it can use the same unidirectional tread pattern front and rear but mold it on the carcass in opposite directions so that the overlapped material will not try to unravel.

More Tender-ness

QIn your October Service column, under the response titled “Love me Tender,” you stated that one should add “distilled water to replace that which is gradually boiled off by the Battery Tender.” I’d always been under the impression that Battery Tenders didn’t boil batteries and were safe to leave trickle charging for months. Am I mistaken?

Recall Roster

NHTSA Recall No. 07V362000 Suzuki GSX-R1000 Model year: 2007 No. of units involved: 13,398 Problem: Each time the ignition switch is turned off, the engine control module (ECM) pre-sets the position of the idle speed control (ISC) valve for subsequent engine starting by opening the valve completely and then closing it to a start-up position. Due to the improper shape of the internal mechanism that moves the ISC valve, the valve may remain in the open position instead of moving to the correct startup position. This can result in no-load engine idle speeds as high as 5000 rpm the next time the engine is started. If the rider chooses to operate the motorcycle in this condition, that rider may experience difficulty that could result in a crash. Remedy: Dealers will replace both the ISC valve and the ECM. Owners not receiving this free remedy may contact Suzuki at 714/572-1490.

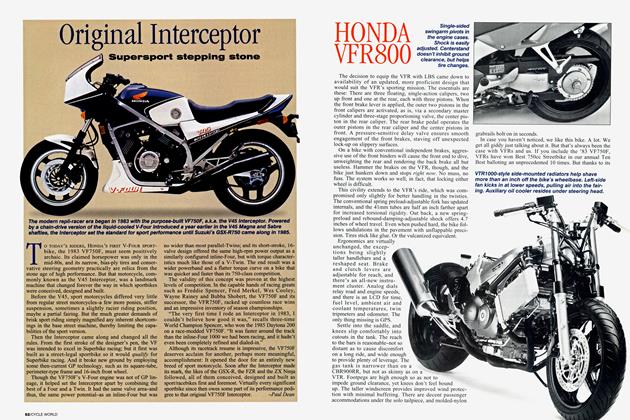

NHTSA Recall No. 07V359000 Honda VFR800 Interceptor Model years: 2002-05 No. of units involved: 6952 Problem: The fairing sub-harness (a section of the main wiring harness) transfers the electrical grounding load of the headlights, front turnsignals, instrument panel and various relays to the main wiring harness via an 18-pin connector. Under certain conditions, the ground-wire terminals inside the connector can overheat, resulting in melting of the connector and a loss of power to various circuits. As a result, a loss of critical lighting or engine power may occur without warning, which could cause a crash. Remedy: Dealers will install a redesigned sub-harness. If necessary, the main wiring harness will also be replaced. Owners not receiving this free remedy may contact Honda at 866/784-1870.

If water is indeed boiled off, what can be done to sealed batteries such as AGM and gel varieties, which have no way “in” to replenish the electrolyte. Am I decreasing the life of my batteries by putting them on and taking them off a Battery Tender in between rides?

Steve Lawrence Thornton, Colorado

A You may recall that the author of that letter, James Graven, has kept the battery in his ’95 Suzuki RF900 alive and well for almost 11 years but only 15,000 miles. That’s an average of just under 1400 miles a year or 113 miles a month, which means the battery has spent most of its life on a Battery Tender. Obviously, the battery hasn’t suffered a shortened life as a result, since it is extremely rare that one will last 11 years under any circumstances.

For the most part, you are correct in assuming that Battery Tenders do not boil off water-at least in significant quantities. But considering the sheer amount of time Mr. Graven’s battery spent on the Tender over an 11 -year period, I thought it reasonable to assume that somewhere along the line, he had to top off the water level. Besides, I simply stated that he evidently had added water, not that everyone using a Battery Tender should add water.

With sealed batteries, water loss is not a concern. The same containment system that keeps you out of the battery’s cells also keeps the electrolyte in them. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631 -0651 ; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www. cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue