Invisible seal

TDC

Kevin Cameron

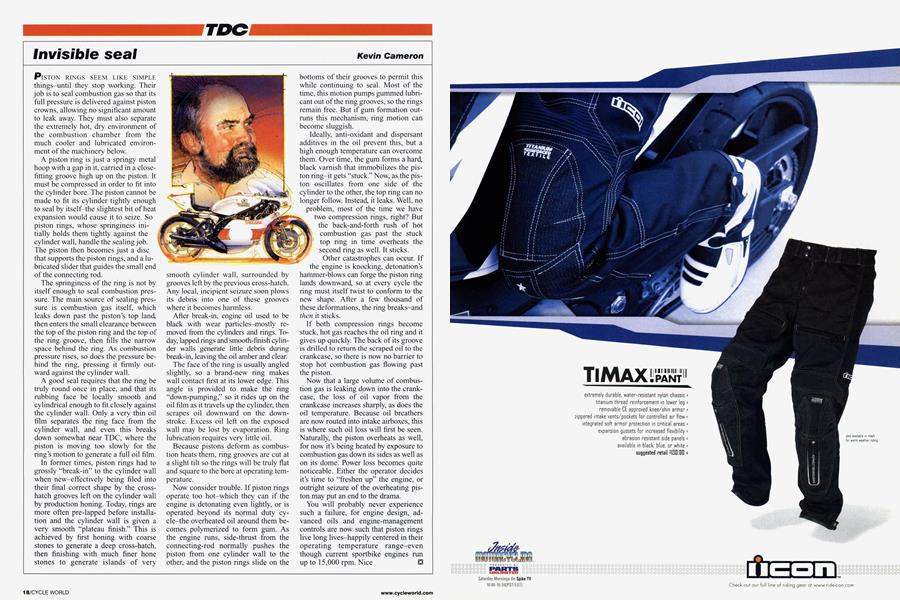

PISTON RINGS SEEM LIKE SIMPLE things-until they stop working. Their job is to seal combustion gas so that its full pressure is delivered against piston crowns, allowing no significant amount to leak away. They must also separate the extremely hot, dry environment of the combustion chamber from the much cooler and lubricated environment of the machinery below.

A piston ring is just a springy metal hoop with a gap in it, carried in a closefitting groove high up on the piston. It must be compressed in order to fit into the cylinder bore. The piston cannot be made to fit its cylinder tightly enough to seal by itself-the slightest bit of heat expansion would cause it to seize. So piston rings, whose springiness initially holds them tightly against the cylinder wall, handle the sealing job. The piston then becomes just a disc that supports the piston rings, and a lubricated slider that guides the small end of the connecting rod.

The springiness of the ring is not by itself enough to seal combustion pressure. The main source of sealing pressure is combustion gas itself, which leaks down past the piston’s top land, then enters the small clearance between the top of the piston ring and the top of the ring groove, then fills the narrow space behind the ring. As combustion pressure rises, so does the pressure behind the ring, pressing it firmly outward against the cylinder wall.

A good seal requires that the ring be truly round once in place, and that its rubbing face be locally smooth and cylindrical enough to fit closely against the cylinder wall. Only a very thin oil film separates the ring face from the cylinder wall, and even this breaks down somewhat near TDC, where the piston is moving too slowly for the ring’s motion to generate a full oil film.

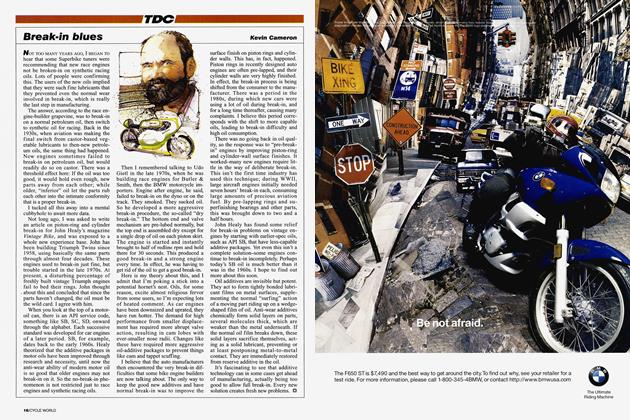

In former times, piston rings had to grossly “break-in” to the cylinder wall when new-effectively being filed into their final correct shape by the crosshatch grooves left on the cylinder wall by production honing. Today, rings are more often pre-lapped before installation and the cylinder wall is given a very smooth “plateau finish.” This is achieved by first honing with coarse stones to generate a deep cross-hatch, then finishing with much finer hone stones to generate islands of very smooth cylinder wall, surrounded by grooves left by the previous cross-hatch. Any local, incipient seizure soon plows its debris into one of these grooves where it becomes harmless.

After break-in, engine oil used to be black with wear particles-mostly removed from the cylinders and rings. Today, lapped rings and smooth-finish cylinder walls generate little debris during break-in, leaving the oil amber and clear.

The face of the ring is usually angled slightly, so a brand-new ring makes wall contact first at its lower edge. This angle is provided to make the ring “down-pumping,” so it rides up on the oil film as it travels up the cylinder, then scrapes oil downward on the downstroke. Excess oil left on the exposed wall may be lost by evaporation. Ring lubrication requires very little oil.

Because pistons deform as combustion heats them, ring grooves are cut at a slight tilt so the rings will be truly flat and square to the bore at operating temperature.

Now consider trouble. If piston rings operate too hot-which they can if the engine is detonating even lightly, or is operated beyond its normal duty cycle-the overheated oil around them becomes polymerized to form gum. As the engine runs, side-thrust from the connecting-rod normally pushes the piston from one cylinder wall to the other, and the piston rings slide on the bottoms of their grooves to permit this while continuing to seal. Most of the time, this motion pumps gummed lubricant out of the ring grooves, so the rings remain free. But if gum formation outruns this mechanism, ring motion can become sluggish.

Ideally, anti-oxidant and dispersant additives in the oil prevent this, but a high enough temperature can overcome them. Over time, the gum forms a hard, black varnish that immobilizes the piston ring-it gets “stuck.” Now, as the piston oscillates from one side of the cylinder to the other, the top ring can no longer follow. Instead, it leaks. Well, no

problem, most of the time we have two compression rings, right? But the back-and-forth rush of hot combustion gas past the stuck top ring in time overheats the second ring as well. It sticks. Other catastrophes can occur. If the engine is knocking, detonation’s hammer-blows can forge the piston ring lands downward, so at every cycle the ring must itself twist to conform to the new shape. After a few thousand of these deformations, the ring breaks-and then it sticks.

If both compression rings become stuck, hot gas reaches the oil ring and it gives up quickly. The back of its groove is drilled to return the scraped oil to the crankcase, so there is now no barrier to stop hot combustion gas flowing past the piston.

Now that a large volume of combustion gas is leaking down into the crankcase, the loss of oil vapor from the crankcase increases sharply, as does the oil temperature. Because oil breathers are now routed into intake airboxes, this is where such oil loss will first be seen. Naturally, the piston overheats as well, for now it’s being heated by exposure to combustion gas down its sides as well as on its dome. Power loss becomes quite noticeable. Either the operator decides it’s time to “freshen up” the engine, or outright seizure of the overheating piston may put an end to the drama.

You will probably never experience such a failure, for engine design, advanced oils and engine-management controls are now such that piston rings live long lives-happily centered in their operating temperature range-even though current sportbike engines run up to 15,000 rpm. Nice □

View Full Issue

View Full Issue