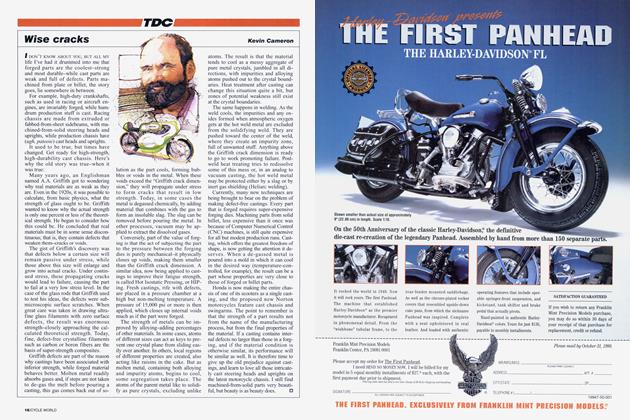

Room at the top

TDC

Kevin Cameron

THE COMING OF FOUR-STROKE GP RACing this spring will focus intense development on combustion chamber design.

At mid-century, when strokes were bigger than bores and all engines had two valves per cylinder, the way to get rapid, efficient combustion was to direct intake flow into the cylinder on a tangent, creating a turbulent rotary charge swirl around the cylinder axis. Roomy, low-compression combustion chambers allowed this energetic motion to persist all the way to TDC, spreading flame rapidly from the sparkplug(s).

Greedy humans always want more power, and higher revs are a way to get it, by performing the power-producing cycle more times per second. To get the larger valve area that higher revs require for adequate cylinder-filling, intake and exhaust valve stems were tilted apart to a large included angle, so the valve heads formed a triangle with the flat piston crown as its base. The wider the valve angle and the deeper the combustion chamber bowl, the greater the available room for valves.

This worked only until better fuels allowed use of higher compression, and the shortcut to high compression was tall piston domes. There was a drawback: Deep chambers and mountainous piston domes created excessive combustion chamber surface area, and therefore cooling problems. Also, the deeper the piston poked into the chamber, the more it interfered with flame-speeding charge motion and turbulence. This required earlier ignition, causing more heat loss and piston temperature problems.

About this time, people discovered that if ports were flow-bench developed, valves didn’t have to be all that big. With smaller valves, the chamber could be made shallower, with a narrower valve angle and a lower-domed piston. The 90-110-degree valve angle of prewar designs shrank in latter-day two-valve engines like Norton Twins and the Kawasaki Z-l to more like 60 degrees. Bores and strokes became nearly equal. The resulting smaller combustion chamber surface area cut heat loss. Combustion was faster now because the flame no longer had to embrace a mountain built atop the piston.

The first modern four-valve engines were built to achieve higher rpm, not better combustion. Honda’s air-cooled GP engines of the 1960s revved as high

as 21,000 rpm. Lots of little valves could be controlled at revs that would toss fewer, bigger ones. Honda’s four-valve designs had conventional large included angles and tall piston domes, adding up to hot operation and a need for more than 50 degrees of spark lead. Bores grew to about 1.1 times bigger than strokes.

What about liquid-cooling? Early attempts to use four valves in liquidcooled car engines were no improvement over two-valve equivalents. Keith Duckworth (the “worth” in Cosworth) found a way forward in the mid-1960s. By making the bore about 1.3 times bigger than the stroke, plenty of four-valve area could fit into a much flatter combustion chamber with a flat-topped piston, and intake and exhaust valve stems set at only 32 degrees to each other. Even though the bore was large, combustion chamber surface area was moderate because of the flatness of piston and chamber.

To create turbulence with four valves, Duckworth employed “tumble,” a rotary charge motion around a horizontal axis, perpendicular to the intake ports. Charge entered through the valves, flowed across the head, down the cylinder wall on the far side, back across the piston crown and back up the near cylinder wall. In a really smooth chamber, tumble motion lasted all the way to TDC, just as axial swirl had done in the best twovalve engines. It worked-ignition timing dropped into the high 20s.

Soon everyone was doing it, and then overdoing it. In the 1980s and ’90s, motorcycle manufacturers tried to push bore/stroke ratios to 1.5 or more. But often, more was lost through slowed combustion than was gained from the higher rev capability of a shorter stroke. As the bore was made bigger, the flame path became longer. The shorter the stroke, the thinner the combustion space became vertically-like a poker chip-with less “headroom.” The tighter a chamber is made, the faster charge motion loses energy from wall friction. With less turbulence remaining near TDC to speed combustion, these poker-chip chambers pushed ignition timing back up into the 40-45-degree range. One 1980s short-stroke engine had to return to 1 : its previous longer stroke, and others took years to equal the power (in racing form) of the longerstroke engines they replaced.

Formula One car racing has moved to amazing extremes, with bore/stroke ratios of 2.25 or higher, and ridiculous ignition timing in the 60-degree range. Will four-stroke GP bike engines follow them into that strange territory? All of the MotoGP engines so far announced have at least three cylinders, and so can reach the 16,000 or so rpm they need to make adequate power without resorting to radically short strokes.

Some research done at Ducati suggested they might be tempted to go GP racing with an extremely oversquare Twin, with dimensions like 1 14 x 48.4mm. Race Director Claudio Domenicali, however, has recently said they rejected this choice because so large a bore had potential for serious combustion problems. The current Superbike race engine is at 104 x 57.4mm, for a bore/stroke ratio of 1.81. There may also exist a prototype 748 engine with this same bore, for a bore/stroke ratio of 2.36-right up there in F-l territory. A surer path to early success, Ducati decided was to build a 90degree V-Four Desmo engine that acts (and sounds) like a Twin by firing pairs of cylinders together, rather than alternately.

Once a few races have been run, the relative values of peak horsepower and torque curve shape will begin to appear. Will there be an F-l -style horsepower war, leading to ever shorter strokes? Or will the winning factors be more subtle, less easy to define? It’s a new game, and the trend of design has yet to be established.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMad Max Found!

May 2002 By David Edwards -

Leanings

LeaningsA Trip To the Barber

May 2002 By Peter Egan -

Departments

DepartmentsHotshots

May 2002 -

Roundup

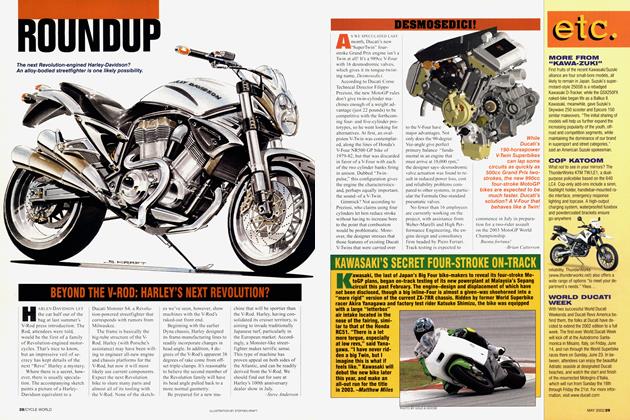

RoundupBeyond the V-Rod: Harley's Next Revolution?

May 2002 By Steve Anderson -

Roundup

RoundupDesmosedici!

May 2002 By Brian Catterson -

Roundup

RoundupKawasaki's Secret Four-Stroke On-Track

May 2002 By Matthew Miles