Living in harmony

TDC

Kevin Cameron

WHAT IS “SIMPLE HARMONIC MOTION” and why do you care? One example is a child on a swing. The essentials are a mass, a restoring force and some kind of driving force to set the mass into oscillatory motion. In our example, the mass is the child, the restoring force is gravity, tending to return the swing to a position pointing at the center of the Earth, and the exciting force is the doting parent, giving the child a push at the top of every swing. A fourth element is friction, tending to remove energy from the oscillating object. In the case of the swing, friction is present as air resistance and sliding friction in the supporting chains or rope.

Motorcycles contain many oscillators. If, after removing the damping oil from t front and rear suspensions, you ride your machine over a bump, it will continue to heave up and down and pitch forward and back for some time afterward. The motorcycle is the mass, the restoring force is the suspension springs and the exciting force is the bump.

Normally, a properly set-up machine does not continue to oscillate after a bump because the suspension rapidly converts bump energy into heat in the damper oil. The dampers are there precisely to prevent bumps from provoking long series of upsetting oscillations-they are devices to provide controlled friction.

Other parts of the machine act as oscillators, but unintentionally. Tires are springy both vertically and laterally, so they can bounce. The fork, consisting of long tubes, cannot be made perfectly rigid so it, too, flexes forward and back and side-to-side. The wheel, tire and brakes are the mass, the flexing fork tubes are the spring, and bumps or other cyclic forces set this system into oscillation. The natural frequency of this system depends upon fork-tube stiffness (stiffer tubes raise the frequency) and upon the mass in motion (the heavier the wheel, tire and brakes become, the lower the frequency).

A bad problem in motorcycle roadracing at the moment is chatter, a rapid judder of the front or rear tire that can occur, as veteran racer Mick Grant once put it, “under conditions of heavy load and high grip.” Cornering increases tire load by 50 to 70 percent, and racing tires and good pavement provide the high grip, so chatter is a cornering phenomenon. The usual condition is front chatter, which can get worse the harder the rider tries to gas it out of a turn, causing the bike to run wide as the tire spends less and less time on the pavement. The vibration may cause double vision! Sometimes changes to tire pressure (which changes tire stiffness) or fork settings can banish chatter, but other times, nothing works. Chatter may not even show up on data acquisition, for all the motion may be in tire and fork-tube flex, with no movement reported by the suspension-motion sensor. Chatter develops because, with the front tire’s bounce frequency being close to the fork’s bending frequency, any reasonably in-step driving force can begin to store energy in these coupled oscillation modes. With little damping to control them, they can build up fast.

If you read the racing press, you know there is continuing talk about “controlled chassis flex.” One aspect of this work attempts to provide a “lateral suspension” when the machine is leaned far over in turns. Another tries to “tune out” troublesome specific oscillation frequencies. By making the chassis less stiff in a given direction, the oscillation of chassis parts in that direction can be shifted to a lower frequency. That may take one oscillation out of step with another, such as tire bounce, fork flex or steering-head lateral twist. Oscillations develop fast when two or more oscillators move in step (both storing and releasing energy together), but they can be suppressed if their frequencies are widely separated.

Damping is valuable when it prevents build-up of unwanted oscillations, but it just adds resistance to motion at other frequencies. This is why suspension engineers love to show that motorcycles do some things better with no damping at all to interfere with free wheel movement. At the recent Laguna Seca World Superbike round, I asked Ducati engineer Corrado Cecchinelli if he would like a kind of suspension that damped only the unwanted oscillation modes-such as pitch, heave, fork flex and tire bounce. He replied that this would be a very valuable technology but that it lies outside Ducati’s engineering purview.

\ Now it appears that such a technology is near readiness for racing use and, in due course, for commercial application. The use of research tools such as on-board data acquisition and various forms of shakers (devices for applying cyclical and other driving forces to vehicles) has allowed many phenomena to be teased out which were previously mysterious. I have myself seen, courtesy of Robin Tuluie at MTS (a major “shaker-maker”), a motorcycle on a two-post shaker suddenly start to violently wag its front wheel back and forth at about 22 cycles per second. Track research has revealed the existence in hard cornering of a lateral oscillation in the range of 12-13 cycles. It seems to result from cyclic buckling, sliding and re-adhesion of the tire footprint.

And now consider the dad pushing his child on the swing. Tires made by traditional means are remarkably round, well-balanced and free from force variation-differences in stiffness around the tire. Nevertheless, the coming of new methods, capable of holding even tighter tolerances, has revealed that even small tire imperfections can stimulate the build-up of unwanted suspension or chassis oscillations. These imperfections constitute a cyclic driving force, just like the dad pushing his child. At about 80 mph, force variation or outof-round in a tire comes into step with the fork-bending mode. More accurately made tires have already revealed their usefulness as a tool to combat chassis oscillations and there is a lot more yet to be learned.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Other Side of Speed

November 2002 By David Edwards -

Leanings

LeaningsA Morning In Italy

November 2002 By Peter Egan -

Departments

DepartmentsHotshots

November 2002 -

Roundup

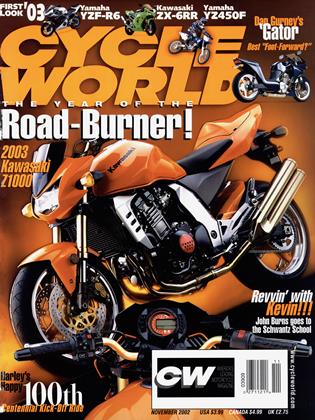

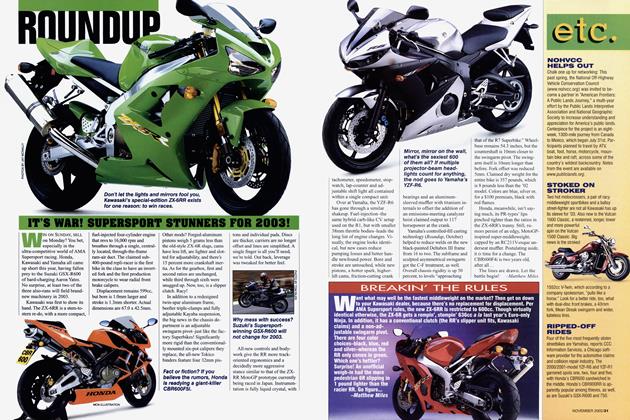

RoundupIt's War! Supersport Stunners For 2003!

November 2002 By Matthew Miles -

Roundup

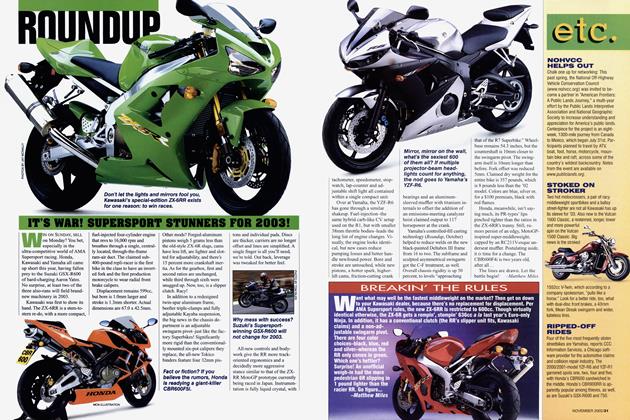

RoundupBreakin' the Rules

November 2002 By Matthew Miles -

Roundup

RoundupEtc.

November 2002