Turning

TDC

Kevin Cameron

FRONT-TIRE LOAD CAPACITY IS A CENtral problem of the motorcycle. To steer quickly and with minimum effort, the front tire must have a small footprint. To carry the heavy braking and cornering load of a powerful motorcycle, it needs a large footprint. It can’t be both.

An inexperienced racer who brakes all the way to the apex can shred a front tire in five laps because it is too small for this kind of punishment. Grand Prix 250s and 125s typically have apex corner speeds 10-15 percent higher than do either 500s or Superbikes. The reason is that a front tire small enough for agile handling is too small for big-bike load.

How does this work? In high school, we learn the Coulomb Friction Law, which states that the friction of a moving slider increases in direct proportion to the applied load. If this were true of rubber, there would be no front tire problem. As a motorcycle was made heavier, its grip would increase in proportion. A tire 4 inches wide would have the same grip as an 8-inch tire.

It doesn’t work that way. Why not? As rubber is pressed ever more firmly against pavement, its softness allows it to progressively conform more and more deeply to the irregularities of the surface. This results in increased actual area of contact and so, increased friction. But unlike other solids, rubber’s elasticity is not linear. The first bit of applied pressure deforms the rubber quite a bit, but increasing the pressure fails to increase the deformation in proportion-a case of diminishing returns. This is why a large footprint gives more grip than a smaller one under the same applied load.

The necessary difference between front and rear tire sizes is responsible for the modern style of pavement motorcycle riding. Because the wider rear tire has much more grip than the narrower front, the motorcycle performs better during acceleration (load mainly on the large rear tire) than during either braking (load mainly on the small front) or very high corner speed (about equal loads on front and rear, thereby overloading the front). Top riders tend to enter corners at less than the maximum possible speed, get the machine turned early, then use as much road as possible for maximum acceleration onto the next straight.

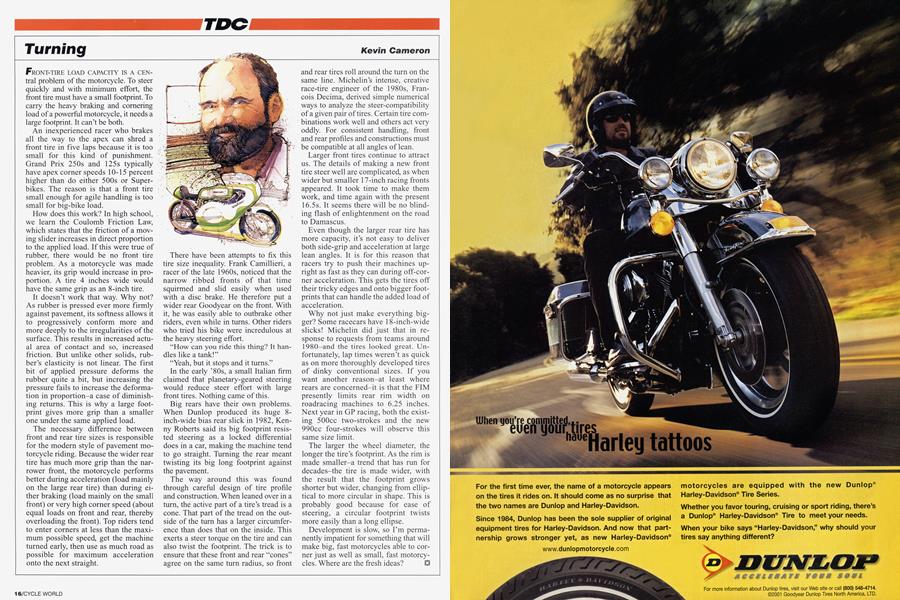

There have been attempts to fix this tire size inequality. Frank Camillieri, a racer of the late 1960s, noticed that the narrow ribbed fronts of that time squirmed and slid easily when used with a disc brake. He therefore put a wider rear Goodyear on the front. With it, he was easily able to outbrake other riders, even while in turns. Other riders who tried his bike were incredulous at the heavy steering effort.

“How can you ride this thing? It handles like a tank!”

“Yeah, but it stops and it turns.”

In the early ’80s, a small Italian firm claimed that planetary-geared steering would reduce steer effort with large front tires. Nothing came of this.

Big rears have their own problems. When Dunlop produced its huge 8inch-wide bias rear slick in 1982, Kenny Roberts said its big footprint resisted steering as a locked differential does in a car, making the machine tend to go straight. Turning the rear meant twisting its big long footprint against the pavement.

The way around this was found through careful design of tire profile and construction. When leaned over in a turn, the active part of a tire’s tread is a cone. That part of the tread on the outside of the turn has a larger circumference than does that on the inside. This exerts a steer torque on the tire and can also twist the footprint. The trick is to ensure that these front and rear “cones” agree on the same turn radius, so front and rear tires roll around the turn on the same line. Michelin’s intense, creative race-tire engineer of the 1980s, Francois Decima, derived simple numerical ways to analyze the steer-compatibility of a given pair of tires. Certain tire combinations work well and others act very oddly. For consistent handling, front and rear profiles and constructions must be compatible at all angles of lean.

Larger front tires continue to attract us. The details of making a new front tire steer well are complicated, as when wider but smaller 17-inch racing fronts appeared. It took time to make them work, and time again with the present 16.5s. It seems there will be no blinding flash of enlightenment on the road to Damascus.

Even though the larger rear tire has more capacity, it’s not easy to deliver both side-grip and acceleration at large lean angles. It is for this reason that racers try to push their machines upright as fast as they can during off-corner acceleration. This gets the tires off their tricky edges and onto bigger footprints that can handle the added load of acceleration.

Why not just make everything bigger? Some racecars have 18-inch-wide slicks! Michelin did just that in response to requests from teams around 1980—and the tires looked great. Unfortunately, lap times weren’t as quick as on more thoroughly developed tires of dinky conventional sizes. If you want another reason-at least where rears are concerned-it is that the FIM presently limits rear rim width on roadracing machines to 6.25 inches. Next year in GP racing, both the existing 500cc two-strokes and the new 990cc four-strokes will observe this same size limit.

The larger the wheel diameter, the longer the tire’s footprint. As the rim is made smaller-a trend that has run for decades-the tire is made wider, with the result that the footprint grows shorter but wider, changing from elliptical to more circular in shape. This is probably good because for ease of steering, a circular footprint twists more easily than a long ellipse.

Development is slow, so I’m permanently impatient for something that will make big, fast motorcycles able to corner just as well as small, fast motorcycles. Where are the fresh ideas?

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSpanish Flyers

September 2001 By David Edwards -

Leanings

LeaningsAncient Beemer Update

September 2001 By Peter Egan -

Departments

DepartmentsHotshots

September 2001 -

Roundup

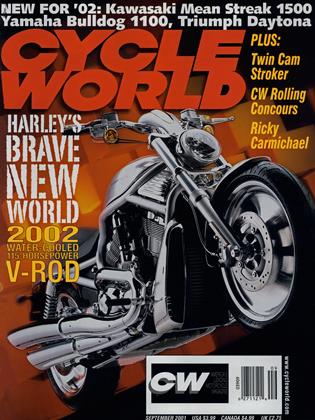

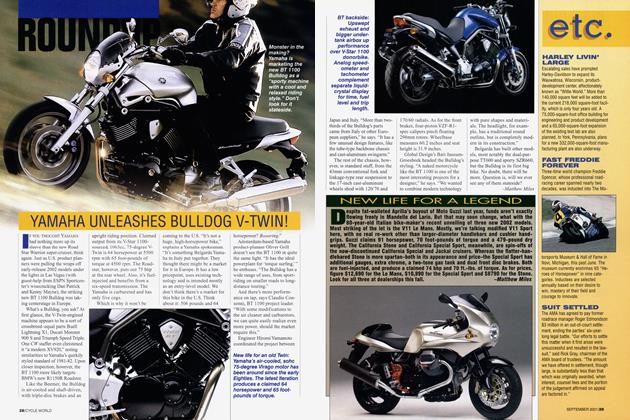

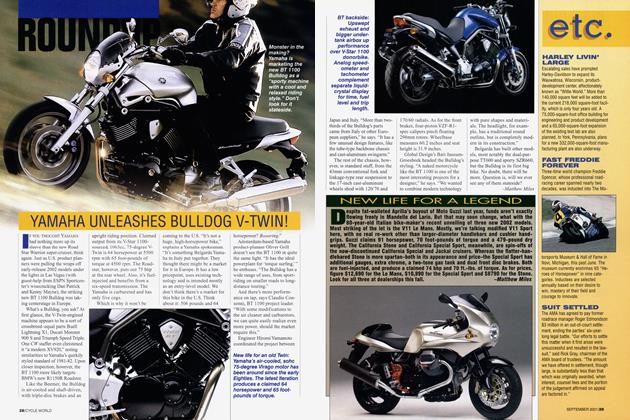

RoundupYamaha Unleashes Bulldog V-Twin!

September 2001 By Matthew Miles -

Roundup

RoundupNew Life For A Legend

September 2001 By Matthew Miles -

Roundup

RoundupEct.

September 2001