SERVICE

Paul Dean

Duel on the dyno

I finally took delivery of my Kawasaki ZX-12R after a very long wait. My dad owns a Suzuki GSX1300R Hayabusa, and we thought it would be fun, once I got my bike fully broken in, to dyno them back-to-back. My question is, does running a bike on a dyno hurt the engine or any of its components? We don’t want to damage our steeds just to see who has bragging rights. The dyno that is available to us is a 4-year-old Dynojet, not an eddy-current brake style, and I’ve watched other bikes being run on it. Usually, the operator makes three idle-to-rev-limiter runs and one all-gear run.

Tyson Cott Council Grove, Kansas

Not to worry: One idle-to-redline run on a Dynojet is no more stressful on the engine than a one-gear, full-throttle blitz up through the entire rpm range on the street. So, if you make three or four dyno passes, that’s the equivalent of running the engine up to redline at full throttle through three or four gears.

Technically, a Dynojet dyno is not a dynamometer; it’s actually an accelerometer. It calculates how much time is required for the engine to accelerate a mass of known weight (the dyno ’s heavy steel drum, driven by the bike ’s rear wheel) from one engine speed to another. Software in the dyno ’s computer then calculates how much work was performed while the drum was being accelerated, then converts that work into units of horsepower, which are mathematically translated into torque figures.

This is kind of a back-door approach to calculating an engine’s output, but accelerometers are simple to use, very easy on the engine and relatively inexpensive to produce. For most civilian purposes, they work just fine.

Brake dynos gather their information by holding engine rpm precisely at predetermined settings (usually every 250 or 500 rpm) long enough for the revs to stabilize before moving on to the next level. They do this by providing a variable resistance to engine rpm through the use of a special “brake ” of some kind—usually one that employs water, oil or an electrical “eddy ” current to create the resistance. The dyno measures the amount of torque delivered to the

brake at each desired rpm level, then those numbers are used to calculate engine torque and horsepower.

Brake dynos provide more accurate and repeatable results than accelerometers, which is why they are preferred by companies involved in the development of engines or high-performance equipment. But brake dynos generally are costlier and more time-consuming to operate; and because they require an engine to be held at wide-open-throttle under full load at each rpm setting, they also are much harder on engine components. Thus, it is not at all uncommon for an engine to fail on a brake dyno, but such a thing rarely occurs on an accelerometer.

Can’t stand the cold

I own a 1993 Kawasaki ZX-11 that has 30,000 miles on it, and it has been acting strangely. When the engine is cold, especially at the start of the first ride of the day (regardless of ambient temperature), as soon as I let out the clutch to begin moving, the engine immediately dies. No matter how easily I let out the clutch, the engine dies, and it will do so until it gets good and warm. The sudden manner in which the engine quits the moment the clutch is even slightly released makes me think that the kickstand kill switch has something to do with the problem, but I can’t imagine how the engine warming up would affect the switch’s operation. When this occurs, the engine dies exactly as it does when you try to ride away with the stand down. This problem would be no big deal except that if there really is something wrong with this switch, I wouldn’t want it to act up and kill the

engine at a critical moment-like when passing a string of cars on the highway in the face of oncoming traffic. Got any suggestions? Eric W. Pope Posted on America Online

Sounds like the sidestand switch indeed is the culprit, but to make sure, here is an easy diagnostic procedure: Find the wire that leads from the switch and follow it up toward the main wiring harness until you come to a small, twoprong connector. Unplug that connector, then use a temporary jumper of some sort to link the two contacts in the upper (female) half of the connector, bypassing the switch altogether. Now start the engine (it should be cold, of course), put the transmission in gear and release the clutch. If the engine continues running, the sidestand switch is faulty and you ’ll have to replace it. If you don’t care to retain a sidestand switch, you can either

bypass it with a permanent jumper or cut off the upper connector altogether and solder the two wires together.

Why does the switch malfunction only when the engine is cold? My best guess is that due to its proximity to the left-side exhaust system, the switch is being affected by heat radiated from the exhaust, causing it to behave much like a thermostat. When the switch is cold, the metal contacts in its interior, which must physically touch each other to complete the ignition circuit, are not quite making contact when the stand is fully retracted; but after exposure to the considerable heat emanating from the exhaust pipe, the metal expands just enough to make sufficient contact. It sounds bizarre, but I’ve seen similar behavior in other simple electrical components.

If the engine still stalls, however, there obviously is trouble somewhere else, although I have no idea where it might be. There is no other logical explanation for the symptoms you ve described. Someone with excellent mechanical and electrical diagnostic skills would have to examine the bike in person and track down the cause of the cold-engine stalling problem.

Out of plumb

I have a ’94 Honda GL1500 Gold Wing that has 25,000 miles on the odometer. I’m currently my second set of tires, and both the original (Dunlops) and this set (Metzeier ML2) have worn lumpy, especially the front. The first set lasted 14,000 miles, and both sets still have about 3/32-inch of tread remaining. The wear seems to be more on the left than on the right, but I don’t think the left side of the bike weighs more than the right. My wife almost always rides with me, and she doesn’t weigh more than 110 pounds soaking wet. Plus, I don’t carry anything in the saddlebags that weighs more than a couple of ounds. So, why do my tires get this pattern? Ken Van Horn Posted on America Online What’s more, if your wife is rather short-and based on your description of her, it sounds like she very well might be—and you are of at least average height, chances are good that she has to lean slightly to one side or the other to see around your helmet and get a decent view of the road ahead. If she usually leans to the right, you then have to lean the bike even farther to the left to compensate for the shift in the overall center of gravity. You may not be aware that she is tilting the upper part of her body to one side, because you can’t see her when you’re moving. But I’ve witnessed this type of behavior with passengers on other bikes, and I’ve had it happen to me on several occasions. Every time I became aware of it, I then observed that on the road, my bike was constantly leaning to one side or the other.

Not too long ago, I answered a similar inquiry about tires wearing more on the left side than on the right. Over the past few months, however, I've gotten several more letters asking about this phenomenon, so apparently it’s time to visit the subject once again.

First of all, the tires on most motorcycles tend to wear more quickly on the left side than the right because most roads are crowned. A typical two-lane road, for example, is highest in the very middle, right at its centerline, and lowest on the outsides. This allows rainwater to

run off onto the shoulder rather than accumulating on the surface and causing hydroplaning. So, no matter in which direction you are traveling, the roadway slopes slightly to the right. To keep your Wing going straight, you must compensate for the angle of the road by leaning the bike very slightly to the left. Over time, that causes more wear on the left sides of the tires than on the right. In countries where they drive on the left side of the road, the opposite occurs and tires wear more rapidly on the right.

As far as the cupping is concerned, that’s normal as well, especially for an enormous bike, such as a Gold Wing, that usually is ridden two-up. Between the substantial mass of the bike and its two occupants, along with the considerable gyroscopic stability afforded by its heavy wheels and tires, the Wing really doesn’t want to change direction. As you apply pressure on the handlebar to initiate and maintain an arc through a turn, the front tire does manage to herd the big bike around the corner; but in the process of doing so, it squirms and distorts just enough to set up uneven wear patterns. This phenomenon actually occurs on most motorcycles, but it is exaggerated on big-rig touring bikes.

Relieving the weaving

I recently bought a Kawasaki Concours, a like-new 1999 model with 2000 miles on it. This bike comes equipped with radial tires, which I’ve never before had on any of my bikes. I notice that when riding on a smooth, straight road, the bike feels like it’s moving around ever so slightly-kind of like some motorcycles feel when passing over one of those iron grated bridges, though not quite so severe. It does this when I ride alone, but isn’t noticeable with a passenger along. Could this be the tires, or could I have the wrong air pressure in the rear shock?

Russ Fister New Tripoli, Pennsylvania

Radial tires do not cause any kind of low-grade weaving, and neither is the Concours known to have such a condition. What’s more, I don’t know if you have too little air in the shock, because you didn’t tell me what pressure you ’re using. More than likely, though, something else is out of whack. I’d start by doing the easy stuff-checking to ensure that the wheel axles, the swingarmpivot axle and the triple-clamp pinch bolts all are properly torqued. Also check the alignment of the rear wheel (not the chain, the wheel) relative to the front wheel. The best way to do this is with two long, perfectly straight pieces of wood or metal, or a long piece of string.

If none of those areas are problematic, check the preload on the steeringhead bearings; if they’re adjusted too tightly, the bike will exhibit the very kind of behavior you describe. The nut atop the bearings should be tightened only until the front end will just barely flop to one side or the other under its own weight when elevated off the ground and turned a few degrees in either direction.

Competent editor needed

In the Service column that appeared in the May, 2000, issue, two guys posted responses relating to vibration on Honda VFRs from 1998 and up (“VFR=vibe-free riding”). One of them suggested “synchronizing the injectors,” but I don’t know what he is referring to. I also have a VFR Interceptor that vibrates a bit, and I’m a maintenance freak who needs to know about these things, but the service manual makes no mention of such a procedure. What’s the deal? Dario 1011 Posted on America Online

“The deal ” is simple: I made an error in judgment. When editing the letter sent by that reader, Albert Oakley, I failed to clarify his comments so that everyone might understand them. When he referred to “synchronizing the injectors,” what he actually meant was synchronizing the opening of the butterfly valves on all four of the fuel-injection system ’s throttle bodies. The terminology he used is fairly common among bike mechanics, but like so many other terms in motorcycling parlance, it’s not an accurate description of the procedure.

In a fuel-injection system, the throttlebody butterflies perform essentially the same task as the butterflies on a bank of CV carburetors. If they’re not all adjusted to open equally and simultaneously, the amount of mixture fed to each cylinder at any given throttle position could vary enough to cause unequal combustion pressures between cylinders. One of the possible outcomes of that unevenness is minor vibration. Mr. Oakley was simply informing us that after he synchronized his VFR ’s throttle-body butterflies, vibration in the 5500-7600-rpm range was significantly reduced. I apologize for any confusion that my use of his letter may have caused. □

Got a mechanical or technical problem with your favorite ride? Can’t seem to find workable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; or 3) e-mail it to CW1Dean@aol.com. Don’t write a 10-page essay, but do include enough information about the problem to permit a reasonable diagnosis. And please understand that due to the volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

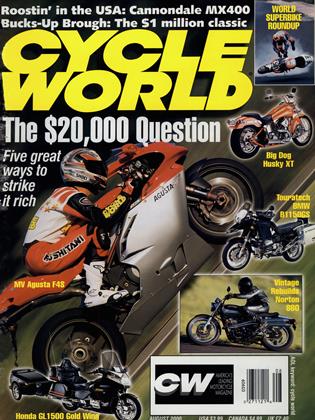

More From This Issue

-

Up Front

Up FrontNed's Sled

August 2000 By David Edwards -

Leanings

LeaningsCharacter Infusion

August 2000 By Peter Egan -

TDC

TDCTwo Crankshafts?

August 2000 By Kevin Cameron -

Departments

DepartmentsHotshots

August 2000 -

Roundup

RoundupEurope Gets Naked!

August 2000 By Matthew Miles -

Roundup

RoundupIndian's Sporting Scout

August 2000 By Wendy F. Black