SERVICE

Paul Dean

Semi-slicks

I have a question about street tires. I know that rubber companies have to make tires that are able to handle any adverse conditions that the weather might bring, most notably rain. So, they put grooves in the tires to displace water and keep those happy wet times happening. But why do they put grooves on the outer edges of the tires? Who is going to go blasting canyons when it rains? Why don’t they make a tire with minimal rain grooves that only extend, say, two-thirds of the way from the center to the edges? That way, folks like myself who take it easy in the wet but like chirpin’ sparks in the dry would have that little extra “edge.” Mike Vanacek Missoula, Montana

That would he a wonderful idea if the tire manufacturers could be issued an iron-clad guarantee that no rider would ever lean very far when riding on wet pavement, or would unexpectedly come upon a patch of water in an otherwise perfectly dry corner. The water could come from any number of common sources-melting snow or ice, remnants of a recent rain, an overactive sprinkler system, a blown radiator on a car that just passed, etc. If you were heeled over on the treadless sides of your tires and couldn’t snap the bike upright quickly enough to get on the grooved part before hitting the water, you d be sliding along on your butt in half a heartbeat.

Same goes for encountering even a small patch of dirt in mid-corner: The difference between a major get-off and passing over the dirt with only a mild twitch could be the grooves—or lack thereof-on the sides of the tread. The tire manufacturers aren 't fools; if they could utilize such a concept to offer a superior sport tire without increasing their product-liability exposure, that tire would already be on the market—and your motorcycle.

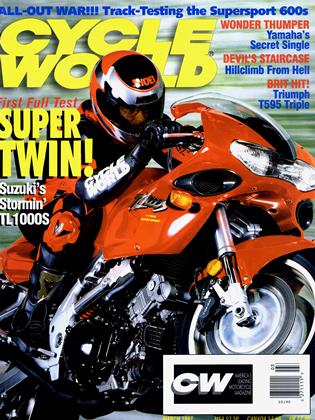

Engineering Triumph?

In your November Roundup section, I read about the new Triumph Daytona T595 and fell in love with the look of this bike (along with its claimed 130 horsepower). I do intend to buy one. I have a question, though, about Triumph’s decision to go from cast-iron cylinder sleeves to hard-coated aluminum bores. Specifically, how will this affect liner wear and engine life? This concerns me, but am I worrying over nothing? Bob Gaisbauer Hudson, Wisconsin

Yes. “Linerless” cylinder-bore technology is nothing new; Kawasaki debuted motocrossers with hard-coated aluminum bores nearly 20 years ago. Since then, this technology has found its way into a wide variety of motorcycle applications, including modern Japanese sportbikes. So, Triumph hasn't exactly ventured into the 21st century with the new T595’s cylinders; if anything, it has merely caught up to the present.

In short, the coating process involves a nickel-silicone material that is electronically plated onto the aluminum of the cylinder walls. The resultant surface is extremely wear-resistant, much more so than with cast-iron liners, and it also transfers heat to the engine 's cooling medium more efficiently. This permits tighter piston-to-cylinder clearances, which, in turn, results in reduced mechanical clatter and better combustion-chamber sealing.

Really, the only significant disadvantage of hard-coated aluminum cylinders is that the absence of replaceable liners makes them harder to repair and more expensive to replace. There are companies, however, such as U.S. Chrome (see the product evaluation in the November, 1996, issue of CW), that perform guaranteed repairs on coated aluminum cylinders that have been damaged.

No invitation needed

Not to stick my nose in where it doesn’t belong, but a couple of points were overlooked in the reply to the “Snip, don’t slip” Harley hop-up letter in the December issue. First, not all adjustable pushrods will go into an Evolution engine without disassembling the rockers. Only a few can, the two that I know of being Crane TimeSavers and Rivera Taper-Lites. Also, a performance cam should never be installed in a late-model Evo unless the INA cam bearing is replaced with a full-complement bearing such as the Torrington unit discontinued by Harley. The INA sometimes fails when subjected to increased stresses, and a loose needle bearing can cause a couple thousand dollars in damage pretty quickly. Again, my apologies for dropping in uninvited. T.J. Richland Center, Wisconsin

First of all, you 're never “uninvited The Service column belongs to all Cycle World readers. Your comments are just as welcome as anyone else ’s.

Second, your advice about the cam bearing is sound. That was an oversight on my part, one that I made partly because most riders don 't have the equipment needed to change the bearing themselves. Extracting the bearing from the crankcase requires a special puller that very few riders have; a Harley dealer or a well-equipped repair shop would need to change the bearing.

But your statement about adjustable pushrods is true only when the cam is still in place. Under those conditions, only a few brands of pushrods, such as those you named, will install without removing the rockers. But that’s rarely the situation, because there's no reason to change the pushrods by themselves; invariably, there ’s other work going on at the same time-new cam, valve job, cylinder-head swap, etc. And when the cam is out of the engine, any of the adjustable pushrods on the market can be installed without removing the rocker assemblies. It’s just more tricky with some than with others.

Actually, T.J., yours was not the only letter I received that claimed my advice on this particular subject was incorrect. There s insufficient room here for step-by-step directions, but rest assured that my recommended method of pushrod installation can be-and routinely is-done by experienced Harley mechanics. S3

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Hopwood Chronicles

March 1997 By David Edwards -

Leanings

LeaningsHow Many Bikes Do You Really Need?

March 1997 By Peter Egan -

TDC

TDCPractical Men

March 1997 By Kevin Cameron -

Letters

LettersLetters

March 1997 -

Roundup

RoundupYamaha Shows Wonder Thumper!

March 1997 By Steve Anderson -

Roundup

RoundupTraction Calling

March 1997 By Don Canet