Chatter chatter

TDC

Kevin Cameron

VEHICLES ARE MADE OF SPRINGS. EVEN A tire is a spring, because if you press it down and release it, it will bounce back up. Tires can also flex and oscillate sideways. Suspensions have springs and, less obviously, the chassis they attach to is also springy.

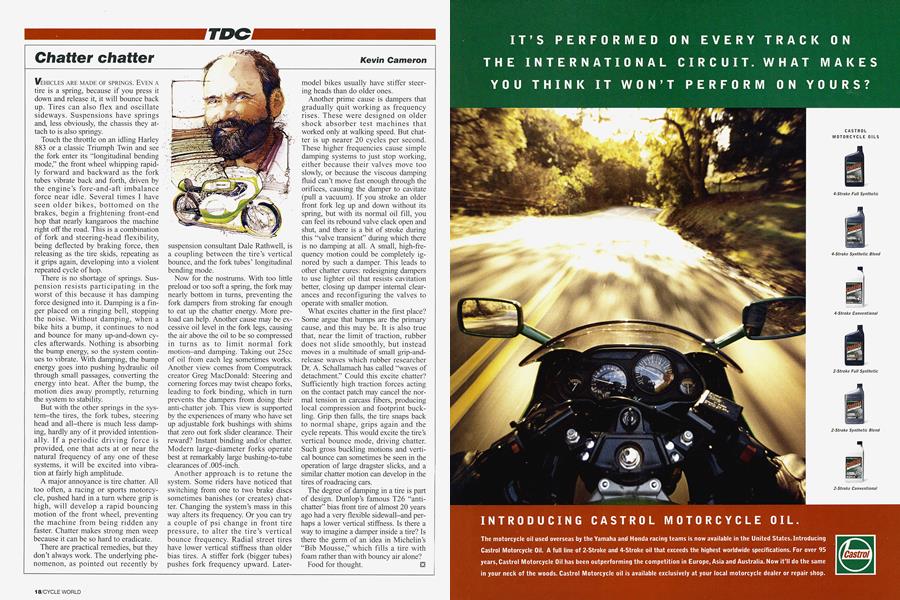

Touch the throttle on an idling Harley 883 or a classic Triumph Twin and see the fork enter its “longitudinal bending mode,” the front wheel whipping rapidly forward and backward as the fork tubes vibrate back and forth, driven by the engine’s fore-and-aft imbalance force near idle. Several times I have seen older bikes, bottomed on the brakes, begin a frightening front-end hop that nearly kangaroos the machine right off the road. This is a combination of fork and steering-head flexibility, being deflected by braking force, then releasing as the tire skids, repeating as it grips again, developing into a violent repeated cycle of hop.

There is no shortage of springs. Suspension resists participating in the worst of this because it has damping force designed into it. Damping is a finger placed on a ringing bell, stopping the noise. Without damping, when a bike hits a bump, it continues to nod and bounce for many up-and-down cycles afterwards. Nothing is absorbing the bump energy, so the system continues to vibrate. With damping, the bump energy goes into pushing hydraulic oil through small passages, converting the energy into heat. After the bump, the motion dies away promptly, returning the system to stability.

But with the other springs in the system-the tires, the fork tubes, steering head and all-there is much less damping, hardly any of it provided intentionally. If a periodic driving force is provided, one that acts at or near the natural frequency of any one of these systems, it will be excited into vibration at fairly high amplitude.

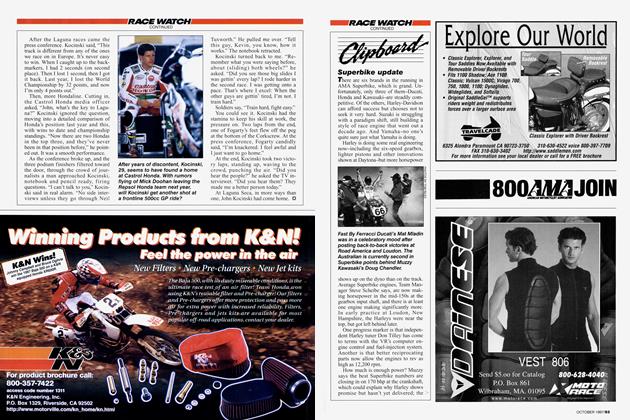

A major annoyance is tire chatter. All too often, a racing or sports motorcycle, pushed hard in a turn where grip is high, will develop a rapid bouncing motion of the front wheel, preventing the machine from being ridden any faster. Chatter makes strong men weep because it can be so hard to eradicate.

There are practical remedies, but they don’t always work. The underlying phenomenon, as pointed out recently by

suspension consultant Dale Rathwell, is a coupling between the tire’s vertical bounce, and the fork tubes’ longitudinal bending mode.

Now for the nostrums. With too little preload or too soft a spring, the fork may nearly bottom in turns, preventing the fork dampers from stroking far enough to eat up the chatter energy. More preload can help. Another cause may be excessive oil level in the fork legs, causing the air above the oil to be so compressed in turns as to limit normal fork motion-and damping. Taking out 25cc of oil from each leg sometimes works. Another view comes from Computrack creator Greg MacDonald: Steering and cornering forces may twist cheapo forks, leading to fork binding, which in turn prevents the dampers from doing their anti-chatter job. This view is supported by the experiences of many who have set up adjustable fork bushings with shims that zero out fork slider clearance. Their reward? Instant binding and/or chatter. Modern large-diameter forks operate best at remarkably large bushing-to-tube clearances of .005-inch.

Another approach is to retune the system. Some riders have noticed that switching from one to two brake discs sometimes banishes (or creates) chatter. Changing the system’s mass in this way alters its frequency. Or you can try a couple of psi change in front tire pressure, to alter the tire’s vertical bounce frequency. Radial street tires have lower vertical stiffness than older bias tires. A stiffer fork (bigger tubes) pushes fork frequency upward. Later-

model bikes usually have stiffer steering heads than do older ones.

Another prime cause is dampers that gradually quit working as frequency rises. These were designed on older shock absorber test machines that worked only at walking speed. But chatter is up nearer 20 cycles per second. These higher frequencies cause simple damping systems to just stop working, either because their valves move too slowly, or because the viscous damping fluid can’t move fast enough through the orifices, causing the damper to cavitate (pull a vacuum). If you stroke an older front fork leg up and down without its spring, but with its normal oil fill, you can feel its rebound valve clack open and shut, and there is a bit of stroke during this “valve transient” during which there is no damping at all. A small, high-frequency motion could be completely ignored by such a damper. This leads to other chatter cures: redesigning dampers to use lighter oil that resists cavitation better, closing up damper internal clearances and reconfiguring the valves to operate with smaller motion.

What excites chatter in the first place? Some argue that bumps are the primary cause, and this may be. It is also true that, near the limit of traction, rubber does not slide smoothly, but instead moves in a multitude of small grip-andrelease waves which rubber researcher Dr. A. Schallamach has called “waves of detachment.” Could this excite chatter? Sufficiently high traction forces acting on the contact patch may cancel the normal tension in carcass fibers, producing local compression and footprint buckling. Grip then falls, the tire snaps back to normal shape, grips again and the cycle repeats. This would excite the tire’s vertical bounce mode, driving chatter. Such gross buckling motions and vertical bounce can sometimes be seen in the operation of large dragster slicks, and a similar chatter motion can develop in the tires of roadracing cars.

The degree of damping in a tire is part of design. Dunlop’s famous T26 “antichatter” bias front tire of almost 20 years ago had a very flexible sidewall-and perhaps a lower vertical stiffness. Is there a way to imagine a damper inside a tire? Is there the germ of an idea in Michelin’s “Bib Mousse,” which fills a tire with foam rather than with bouncy air alone?

Food for thought.

View Full Issue

View Full Issue