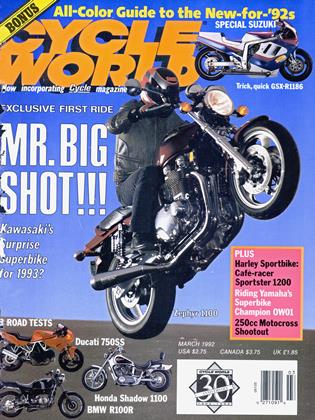

THE TROUBEL WITH GSX-Rs

A FIX FOR THE SHIM-SPITTING BLUES

UNTIL THE 1991 MODELS came along, Suzuki's GSX-R engines employed the same valve-actuating system originated by the GS1100 back in 1980: a single cam lobe operating each matched pair of valves via a forked rocker arm. Valve lash was set with adjusting screws located over the valve tips.

The new-in-’91 design differs quite a bit, using a separate cam lobe and rocker arm for each valve, with shim-type valve adjustment atop each valve stem. And it is in the shim-retaining system where trouble lies in waiting, particularly in high-revving, modified engines that use radical cam profiles. But even stock ’91 or ’92 GSX-R engines are in danger of suffering serious damage if revved high enough to induce valve float.

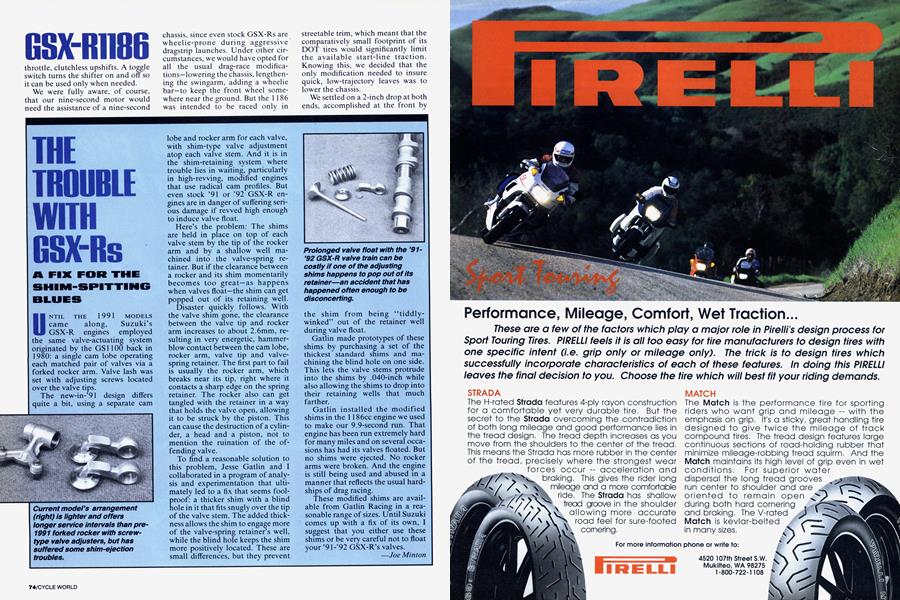

Here’s the problem: The shims are held in place on top of each valve stem by the tip of the rocker arm and by a shallow well machined into the valve-spring retainer. But if the clearance between a rocker and its shim momentarily becomes too great—as happens when valves float—the shim can get popped out of its retaining well.

Disaster quickly follows. With the valve shim gone, the clearance between the valve tip and rocker arm increases to about 2.6mm, resulting in very energetic, hammerblow contact between the cam lobe, rocker arm, valve tip and valvespring retainer. The first part to fail is usually the rocker arm, which breaks near its tip, right where it contacts a sharp edge on the spring retainer. The rocker also can get tangled with the retainer in a way that holds the valve open, allowing it to be struck by the piston. This can cause the destruction of a cylinder, a head and a piston, not to mention the ruination of the offending valve.

To find a reasonable solution to this problem, Jesse Gatlin and I collaborated in a program of analysis and experimentation that ultimately led to a fix that seems foolproof: a thicker shim with a blind hole in it that fits snugly over the tip of the valve stem. The added thickness allows the shim to engage more of the valve-spring retainer’s well, while the blind hole keeps the shim more positively located. These are small differences, but they prevent the shim from being “tiddlywinked” out of the retainer well during valve float.

Gatlin made prototypes of these shims by purchasing a set of the thickest standard shims and machining the blind hole on one side. This lets the valve stems protrude into the shims by .040-inch while also allowing the shims to drop into their retaining wells that much farther.

Gatlin installed the modified shims in the 1186cc engine we used to make our 9.9-second run. That engine has been run extremely hard for many miles and on several occasions has had its valves floated. But no shims were ejected. No rocker arms were broken. And the engine is still being used and abused in a manner that reflects the usual hardships of drag racing.

These modified shims are available from Gatlin Racing in a reasonable range of sizes. Until Suzuki comes up with a fix of its own, I suggest that you either use these shims or be very careful not to float your ’91-’92 GSX-R’s valves.

—Joe Minton

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

March 1992 By David Edwards -

Columns

ColumnsLeanings

March 1992 By Peter Egan -

Columns

ColumnsTdc

March 1992 By Kevin Cameron -

Letters

LettersLetters

March 1992 -

Roundup

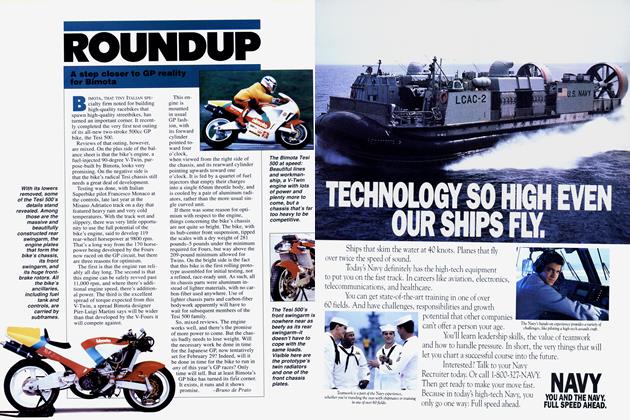

RoundupA Step Closer To Gp Reality For Bimota

March 1992 By Bruno De Prato -

Roundup

RoundupAmerica 1: Gold-Plated Superbike

March 1992 By Jon F. Thompson