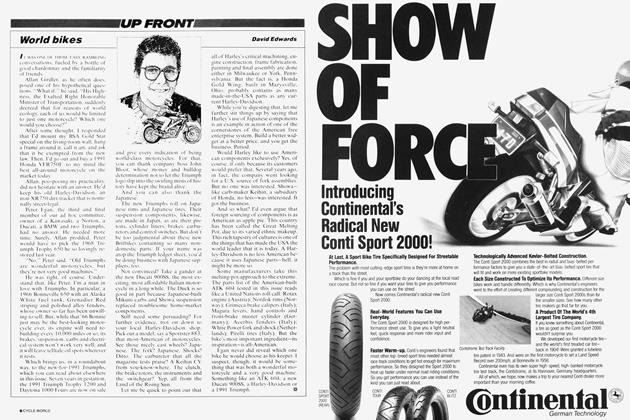

SPECIAL FX

CW PROJECT

A green monster with four-valve heads

MIKE STUBBLEFIELD

DAVID EDWARDS

WHEN HARLEY INTRODUCED its Big Twin Evolution engine in the mid-Eighties, it was quieter, smoother and more reliable than its predecessor. The Blockhead, as it came to be known, was also 10 to 15 percent more powerful than the venerable Shovelhead it replaced. But as far as most performance people were concerned, its output was still more thunder than lightning.

That's why the high-performance Harley aftermarket has tried virtually every trick in the hot-rodder's book — carbs. pistons, cams, big valves, ported heads, performance exhaust systems—to extract more power from the Evolution engine. But no one has attempted to mate modern fourvalve cylinder heads with Harley's pushrod Big Twin. Well, no one until Jim Feuling, owner of Feuling Engineering in Ventura, California, turned his attention to the subject, that is.

The benefits of putting four-valve heads on a 1 larley V-Twin are numerous. For starters, it allows a centrally located sparkplug, which better resists detonation and improves combustion. because it requires a shorter flame and needs less ignition advance to burn the air-fuel mixture. And the combustion chamber can be extremely compact, so it can achieve excellent squish/quench characteristics even with a flat-top piston and a modest compression ratio.

What's more, higher volumetric efficiency is possible, because the area of the four biggest valves that can be placed in a given combustion chamber is larger than the area of the two biggest valves that can be used. Greater area means more flow.

Multi-valve designs also allow valves to cool better: Smaller valves, w hich have a better surface-to-cooling-area ratio, shed heat faster than big valves. Improved thermal efficiencies yield improved octane tolerance. a higher usable compression ratio and a cooler-running engine. In addition, four valves need less cam lift and duration than two valves of similar surface area to move the same amount of air and fuel through the head. And smaller valves have a higher safe upper-rpm limit because they have less mass for the cam to accelerate and for the springs to control.

So, given two otherwise identical engines of equal displacement and dimensions, the four-valve engine should get better mileage, produce a lower level of emissions and pump out more horsepower than a twovalve design.

Which begs the question: With this kind of edge, why hasn't a four-valve head for the Evolution engine already been built? Probably because nobody in the aftermarket—or Harley itself, for that matter—thought it could be done.

Jim Feuling thought it could.

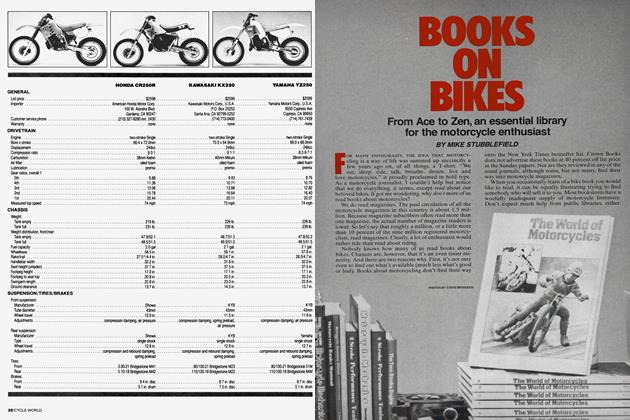

Feuling cast-aluminum heads don't look that different from stock Harley heads. A pair of pushrod tubes still flanks each cylinder, and there's still a carburetor sticking out the right side of the engine, though in Feuling's higher-performance kits, that one mixer is joined by an identical unit on the left. Besides the “4Valve" logo on each head, the only other obvious visual clue is a funny bulge in each header pipe just downstream of the exhaust ports. Look real close and you'll also note that the carbs are bolted onto the ends of a Vshaped. cast-aluminum intake chamber nestled between the cylinder heads. Common wisdom says that the air-fuel mixture should have a straight shot from the carb into the combustion chamber, so the idea of the mix turning a right angle to enter each head can be unsettling.

Mention this to Steve Allstaedt, Feuling’s chief technician, and he replies, “Just ride it," with the quiet confidence of someone accustomed to defending the validity of his boss’ unorthodox ideas.

Jim Feuling grew up around speed. He raced motorcycles as a teenager, and worked in several shops around San Diego, California. He worked for Bonneville Salt Flats legend Don Vesco, and was deeply impressed by the man’s fierce need for velocity. “He lost his wife, he lost his shop, he lost everything. All he cared about was going to Bonneville. It was like a disease. Speed meant everything to him.” says Feuling admiringly.

Feuling’s own need for speed soon put him squarely in the midst of older riders out to make a name for themselves at tracks like Ascot and El Cajon Speedway. In 1961, racing against riders like Swede Savage and a crazy young guy named Malcolm Smith, he won the California Amateur Championship on a 250 BSA.

Before long, Feuling decided it was time to move up to C’lass C ranks. Unable to obtain a legitimate license at 16, he “borrowed” a license from a friend who shall remain nameless, and headed back East. The ensuing years brought a curtailment of the racing career, enrollment in a university pre-med program and then a draft notice, which led to a stint with the Army's Special Forces.

After the military, Feuling drifted for awhile before getting involved in racing again. Except this time it w;as the four-wheeled variety: He built and raced Class I off-road buggies. Bv the early Seventies, he began winning awards as a driver and builder. His vehicles won such major races as the Baja 500 and 1000, the Parker 400 and the 7000-mile Repco Reliability Rally across Australia. In 1976, he was voted the SCORE Mechanic of the Year.

In the late Seventies and early Eighties, Feuling was the brains behind Cyclone Headers. In the Eighties, he began doing R&D work for numerous Detroit firms, including Oldsmobile, Chevrolet, Ford and Chrysler. He built the 2-liter Quad-4 BE engine that powered Oldsmobile's Aerotech streamliner—with A.J. Foyt at the controls—to a new flying-mile record of 267.399 mph in 1987. The BE engine made 1200plus horsepower at 10,500 rpm, or 600 horsepower per 1 OOOcc. In 1 988, the Society of Automotive Engineers awarded Feuling its Outstanding Technical Achievement Award for Innovative Engine Design for his pioneering work on the Aerotech.

An Olds Supreme with an even wilder version of the Aerotech BE engine-built and driven by Feuling himself-has gone 277 mph at Bonneville, and Feuling has his sights set on 300.

So what’s a successful car guy like this doing messing around with something as relatively low-tech as a Flarley Evolution engine? Well, he enjoys the challenge of doing something that everybody says can't be done. But mainly, he just likes Harleys. And anybody who builds 300mph Oldsmobiles, we figured, can probably help Harleys go faster, too.

The thrust of Fueling's work is on air flow, and that’s where his approach differs radically from conventional thinking. Feuling knows air flow better than Bo knows stick-andball games. If you w'ant to know where he finds horsepower, look at the intake and exhaust tracts.

First, the intake area. The movement of the incoming air-fuel mixture is affected by the action of the valves. As the intake valves open, the mixture is drawn into the relative vacuum that develops in each cylinder as the piston moves downward on the intake stroke. Because the nose of the rotating cam lobe holds the valve open only for an instant, this vacuum condition is very brief. At one instant, air is rushing into the cylinder; at the next instant, the flow is cut off. The pressure of the air-fuel mixture is lowered, then raised, over and over again. The speed at which the intake valves operate is so great that their opening and closing action is not unlike that of a pump.

These pulsations are usually mitigated by increasing intake-runner length, which increases the mass, and therefore the inertia, of the incoming mixture. This strategy smooths out the flow, but on a big Evolution motor with space limitations, finding enough room for long runners can be tricky. So, Feuling took another approach. He added a chamber, usually referred to as a plenum, between the carburetors and the intake ports. Because it provides a large holding tank with a volume generous enough to dampen the pumping effect of the intake valves, the plenum calms the turbulence in the manifold without lengthening the intake runners.

In the photos, you'll notice weirdlooking fins around the valve stems in the intake ports. The design is one of Feuling’s breakthroughs. In a conventional design, the air-fuel charge pours through the intake port, only to hit the cylindrical valve stem and tumble past it into the combustion chamber. The streamlined airfoils in the Feuling head channel the intake charge around the stem and right into the combustion chamber.

On the other side of the combustion chamber, Feuling’s research led to another interesting discovery: For every exhaust pulse, there w;as a corresponding pressure wave traveling back up the exhaust tract toward the valve. Watching a racing engine with a transparent intake manifold, Feuling was startled to discover combustion in the intake tract, well upstream of the intake valve. He theorized that the exhaust pressure wave was actually forcing raw fuel back up the intake. along with the high heat of the combustion chamber, creating ignition and pressure before the fuel even reached the cylinder. When he tore down the engine, his suspicions were confirmed: The backs of the intake valves were coated with carbon.

As Feuling himself will admit, exhaust scavenging isn't a new concept. But conventional thinking about scavenging centers on the length of the exhaust pipe for an optimum flow at a predetermined speed. Outside of this ideal “on-the-pipe” sweet spot, the engine runs no better, and may even run worse.

Feuling decided to look at the shape of the pipe, instead of its length. Orthodox thinking says that the pipe should be as smooth and straight as possible. That thinking would be correct, says Feuling, if the exhaust stream was a simple one-way flow. But it isn’t. So he developed his patented Anti-Reversionary device.

Remember those funny bulges in the exhaust? Called AR cones, they act like one-w'ay dams, allowing exiting pressure waves free passage, but preventing returning waves from traveling back up the exhaust stream. The benefit of this, says Feuling, is “charge purity.”

Charge purity results in less carbon build-up throughout the engine, from the combustion chamber back up into the intake tract, because the exhaust gases no longer ignite the charge prematurely or travel up the intake and burn incoming fuel or oil from the valve guides. As a result of the reduction in carbon build-up, the valves, guides and seats wear less, claims Feuling.

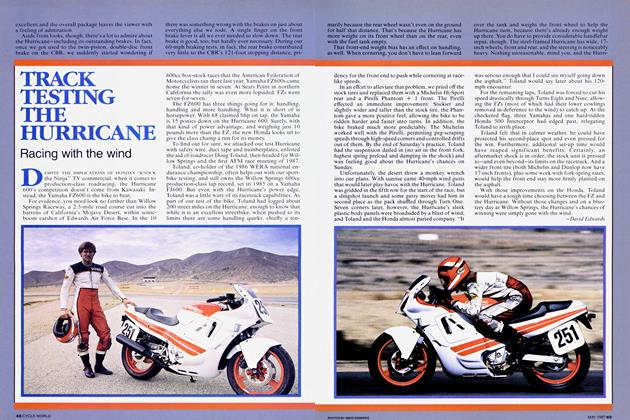

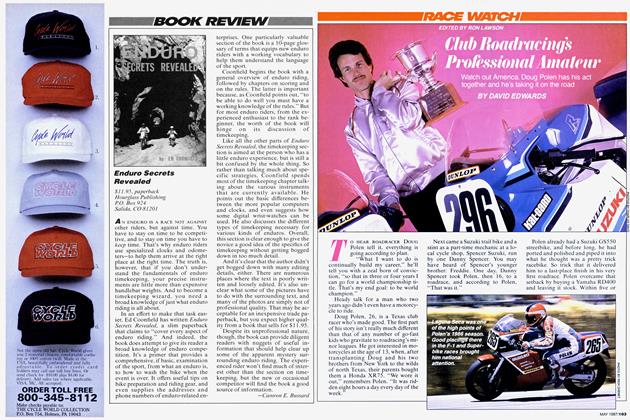

Convinced Feuling was onto something, we asked that he fit his heads to C\\rs long-term test FXRS Sport Edition, that sweetheart of an all-around motorcycle that won Best Standard honors in our 1990 Ten Best Bikes voting. We were in the process of turning the bike into something of a roadburner, a modern-day version of a Brough Superior SSI00 or a Vincent Black Shadow. To that end, we’d already deep-sixed the stock fuel tank and its hokey-looking chrome console, and instead bolted up the sleeker, flat-topped tank from a Low Rider Custom. That tank and both fenders were treated to a new paint job from Harley’s own custom paint shop. In keeping with the bike’s new role, we chose British Racing Green with inset cream panels and gold pinstripes.

We had also upgraded the FXRSSP's suspension, fitting Öhlins Twin Piggyback shocks at the rear and a Bartels’ Performance fork-spring kit up front. In the interest of stanchiontube rigidity, we also bolted on a Harley Screamin' Eagle fork brace.

In anticipation of the added power, we fitted Avon tires—a Super Venom up front and an AM23, in “sprint" compound and one size wider than stock, out back. The front mounted with no problems, but the rear tire was a touch wide, fouling the drive belt and the lower belt guard. We tossed the guard, and a few minutes with a body grinder removed enough tire rubber to clear the belt.

So modified, the FXRS was ready for the Feuling Engineering heads.

The company, going after big numbers at the dragstrip, gave us its full-on Stage III engine mods. This included the four-valve heads, dual 40mm Dell’Orto carbs, solid valve lifters, a high-lift cam, and a KV Products ignition module and rev limiter. Also added was a Dale Walker electric-shift kit. Horsepower, Allstaedt informed us with a smile, was approximately 120. From the factory, a 49-state Evo motor puts out perhaps 60 rear-wheel horsepower. “Peak power is achieved at 6250 rpm," he said, “and it should never be revved over 6500 rpm. Compression ratio is 10.8:1, so unleaded premium gasoline must be used with this engine. Race gas will improve performance, but works best if blended 60/40 with pump gas.”

At the dragstrip, running without air cleaners, the Feuling motor did not disappoint. After some carb rejetting, it stopped the clocks with an 11.59-second run. Speed at the end of the quarter-mile was 1 16.73 mph. When stock, the FXRS-SP had managed a 1 3.1 7/100.1 1-mph showing. Top-gear roll-on times were hindered because the carbs wouldn't accept full throttle in a single whack, instead needing a modulated application to avoid stumbling. Still, 40-to60-mph time dropped slightly from 3.9 seconds stock to 3.8; 60-to-80mph times improved from 4.4 to 3.7. The kitted bike's top-speed improvement was more dramatic. While the stocker peaked at I 14 mph, the project bike steamed to l 35 mph.

Also impressive—but in a negative sense—was the bike's exhaust noise, so obnoxiously loud that the dual pipes' use should be limited to a dragstrip or a sound-proofed dyno chamber. How Feuling and the kit's distributor, Rivera Engineering, hav e the nerve to sell this system for street use is beyond us. We refused to ride the bike on public roads, and asked that a set of mufflers with more baffling be made up.

The silencers that came back —the black-painted units you see in the action photos—still were too loud, but short-shifting let us skulk out of town and onto the backroads, where, finally, we could uncork the big green Hog. But more problems greeted us. First, the Stage III engine wasn't really happy accepting throttle below 3000 rpm. coughing and spitting back. Next, the lower silencer had so little cornering clearance that it was ground to paper-thinness during our first ride. Worse, our second test session ended with an ominous clank from the engine, a needle bearing on the roller tappet letting go and taking out the cam, as well.

After inspection, Allstaedt claimed the trouble with the tappet was an anomaly. Also, running the FX without the electric shifter, we had encountered several false neutrals and the accompanying rpm zings to redline, which may have contributed to the problem. In any event, when the bike came back, it was in Stage II trim, with a less-radical cam and the stock hydraulic lif ters back in place. Also mounted was an admittedly cobby, prototype 2-in to-1 exhaust system, in response to our request for more noise suppression.

On the street, this combinationgood for an estimated 100 horsepower—was a success. Carburetion was nowhere near as persnickety as with the Stage III set-up. with urge from about 2000 rpm. and serious pull starting at 4000 rpm. running past the stock 5000-rpm redline. right through to the new sale rev limit of 6500. We only lost four-tenths of a second at the dragstrip. the Stage II motor (running air cleaners) pulling the bike through the quarter-mile in I 2 seconds flat, with a terminal speed about 5 mph slower than before. Roll-on times were a mixed bag. with the 40-to-60-mph time dropping to 3.5 seconds thanks to the improved carb response, while 60-to-80 took 3.0 seconds, two-tenths of' a second longer than the freer-breathing Stage III engine. Best of all. noise had dropped to levels we could live with, the flat silencer lettmu loose with a strong, throatv rumble that sounded more like it came from, say, a 2()()()cc I)ueati than a I larlev Big Twin.

We do have some reservations about the kits, though. Unless you're interested in all-out performance. we'd sav stay away from the Stage 111 set-up. It's iusi not very friendly on the street. Ñor can we endorse the irresponsibly loud dual-pipe exhaust system. Also, our bike came equipped with a single cable leading from the twistgrip to a juncture box where it met the carb cables. Besides being afflicted with Dell'Orto's traditionally heavy pull, this system occasionally hung up at about 2000 rpm. At this writing. Feuling/Rivera are working on a more positive, pushpull, dual throttle cable, which may be av ailable by the time you read this. For safety's sake, w e hope so.

There are also the questions of price and reliability. Opting for the Stage II kit (which includes the fourvalve heads, the ignition module and rev limiter, two 40mm Dell'Ortos and. when available, the dual throttle cable), then springing for the cam and exhaust system, will set you back a total of $3345, not including shop time if you pay someone to install the parts. That's about $ 1000 more than a conventionally performancekitted. two-valve Big Twin pumping out comparable horsepower.

And while it's hard not to be impressed with Feuling's engineering pedigree, and even if our problem with the Stage III engine was indeed a fluke, the fact is the eight-valve engine kits have been on the market for less than a year, hardly enough time to ascertain the modified engines' long-term reliability. Our Stage II bike has logged 500 trouble-free miles, but anytime you pump an additional 40 horsepower through an engine's components, durability is going to sutler somewhat.

What we can say for sure is that the Stage 11 engine with the 2-in to-1 exhaust system is an impressive com-

bination. one that boots the FXRS into a different league, performancewise. If you've longed for a hot-rod Harley-Davidson with a touch of high-tech, a Feuling eight-valve kit is the way to go.

SUPPLIERS

Rivera Engineering 6416 Western Ave. Whittier, CA 90606 213/693-4273 Feuling Stage II engine kit: $2900 Feuling cam: $145 Feuling exhaust system: $300 Dale Walker electric shifter: $215

Harley-Davidson 3700 N. Juneau Ave. Milwaukee, Wl 53208 414/342-4680 Custom paint: $650 Fuel tank: $232 Screamin’ Eagle fork brace: $94

Avon Tires 407 Howell Way Edmonds, WA 98020 206/771-2115 Super Venom 100/90V19 front: $89 AM23 140/80V16 rear: $146

Noleen Racing 2141 E. Philadelphia, UnitT Ontario, CA 91761 714/947-5773 Öhlins shocks: $429

Time Machine Motorcycle Works 755 W. 17th St. Costa Mesa, CA 92627 714/548-4424 Headlight/fabrication: $250

Bartels' Performance Products 8910 Washington Blvd. Culver City, CA 90232 213/838-3003 Fork-spring kit: $55

View Full Issue

View Full Issue