NEW FOR '93 OMEGA EXPLORED

ALTERNATIVE FRONT SUSPENSION FOR THE MASSES

KEVIN CAMERON

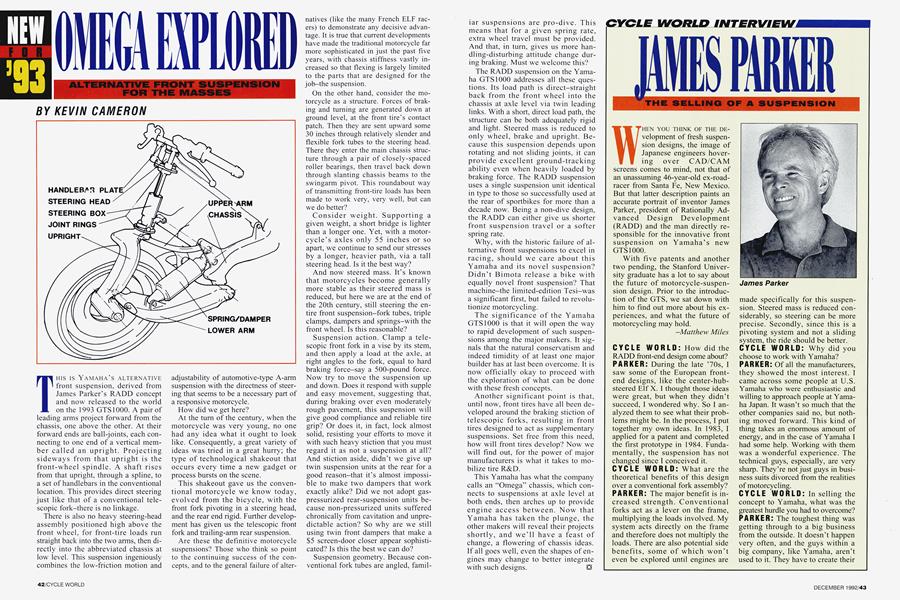

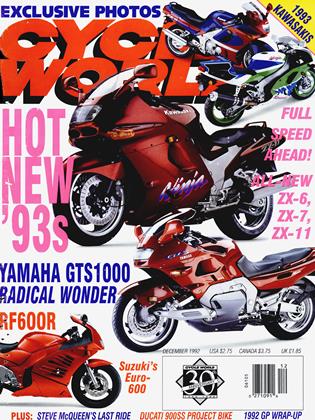

THIS IS YAMAHA'S ALTERNATIVE front suspension, derived from James Parker's RADD concept and now released to the world on the 1993 GTS1000. A pair of leading arms project forward from the chassis, one above the other. At their forward ends are ball-joints, each connecting to one end of a vertical member called an upright. Projecting sideways from that upright is the front-wheel spindle. A shaft rises from that upright, through a spline, to a set of handlebars in the conventional location. This provides direct steering just like that of a conventional telescopic fork-there is no linkage.

There is also no heavy steering-head assembly positioned high above the front wheel, for front-tire loads run straight back into the two arms, then di rectly into the abbreviated chassis at low level. This suspension ingeniously combines the low-friction motion and adjustability of automotive-type A-arm suspension with the directness of steer ing that seems to be a necessary part of a responsive motorcycle.

How did we get here?

At the turn of the century, when the motorcycle was very young, no one had any idea what it ought to look like. Consequently, a great variety of ideas was tried in a great hurry; the type of technological shakeout that occurs every time a new gadget or process bursts on the scene.

This shakeout gave us the conven tional motorcycle we know today, evolved from the bicycle, with the front fork pivoting in a steering head, and the rear end rigid. Further develop ment has given us the telescopic front fork and trailing-arm rear suspension.

Are these the definitive motorcycle suspensions? Those who think so point to the continuing success of the con cepts, and to the general failure of alter-

natives (like the many French ELF rac ers) to demonstrate any decisive advan tage. It is true that current developments have made the traditional motorcycle far more sophisticated in just the past five years, with chassis stiffness vastly in creased so that flexing is largely limited to the parts that are designed for the job-the suspension.

On the other hand, consider the mo torcycle as a structure. Forces of brak ing and turning are generated down at ground level, at the front tire's contact patch. Then they are sent upward some 30 inches through relatively slender and flexible fork tubes to the steering head. There they enter the main chassis struc ture through a pair of closely-spaced roller bearings, then travel back down through slanting chassis beams to the swingarm pivot. This roundabout way of transmitting front-tire loads has been made to work very, very well, but can we do better?

Consider weight. Supporting a given weight, a short bridge is lighter than a longer one. Yet, with a motor cycle's axles only 55 inches or so apart, we continue to send our stresses by a longer, heavier path, via a tall steering head. Is it the best way?

And now steered mass. It's known that motorcycles become generally more stable as their steered mass is reduced, but here we are at the end of the 20th century, still steering the en tire front suspension-fork tubes, triple clamps, dampers and springs-with the front wheel. Is this reasonable?

Suspension action. Clamp a tele scopic front fork in a vise by its stem, and then apply a load at the axle, at right angles to the fork, equal to hard braking force-say a 500-pound force. Now try to move the suspension up and down. Does it respond with supple and easy movement, suggesting that, during braking over even moderately rough pavement, this suspension will give good compliance and reliable tire grip? Or does it, in fact, lock almost solid, resisting your efforts to move it with such heavy stiction that you must regard it as not a suspension at all? And stiction aside, didn't we give up twin suspension units at the rear for a good reason-that it's almost impossi ble to make two dampers that work exactly alike? Did we not adopt gas pressurized rear-suspension units be cause non-pressurized units suffered chronically from cavitation and unpre dictable action? So why are we still using twin front dampers that make a $5 screen-door closer appear sophisti cated? Is this the best we can do?

Suspension geometry. Because con ventional fork tubes are angled, famil jar suspensions are pro-dive. This means that for a given spring rate, extra wheel travel must be provided. And that, in turn, gives us more han dling-disturbing attitude change dur ing braking. Must we welcome this?

The RADD suspension on the Yama ha GTS 1000 addresses all these ques tions. Its load path is direct-straight back from the front wheel into the chassis at axle level via twin leading links. With a short, direct load path, the structure can be both adequately rigid and light. Steered mass is reduced to only wheel, brake and upright. Be cause this suspension depends upon rotating and not sliding joints, it can provide excellent ground-tracking ability even when heavily loaded by braking force. The RADD suspension uses a single suspension unit identical in type to those so successfully used at the rear of sportbikes for more than a decade now. Being a non-dive design, the RADD can either give us shorter front suspension travel or a softer spring rate.

Why, with the historic failure of al ternative front suspensions to excel in racing, should we care about this Yamaha and its novel suspension? Didn't Bimota release a bike with equally novel front suspension? That machine-the limited-edition Tesi-was a significant first, but failed to revolu tionize motorcycling.

The sig~ficance of the Yamaha GTS1000 is that it will open the way to rapid development of such suspen sions among the major makers. It sig nals that the natural conservatism and indeed timidity of at least one major builder has at last been overcome. It is now officially okay to proceed with the exploration of what can be done with these fresh concepts.

Another significant point is that, until now, front tires have all been de veloped around the braking stiction of telescopic forks, resulting in front tires designed to act as supplementary suspensions. Set free from this need, how will front tires develop? Now we will find out, for the power of major manufacturers is what it takes to mo bilize tire R&D.

This Yamaha has what the company calls an "Omega" chassis, which con nects to suspensions at axle level at both ends, then arches up to provide engine access between. Now that Yamaha has taken the plunge, the other makers will reveal their projects shortly, and we'll have a feast of change, a flowering of chassis ideas. If all goes well, even the shapes of en gines may change to better integrate with such designs.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Butt Stops Here

December 1992 By David Edwards -

Leanings

LeaningsTent Revival

December 1992 By Peter Egan -

TDC

TDCGoin' With the Flow

December 1992 By Kevin Cameron -

Letters

LettersLetters

December 1992 -

Roundup

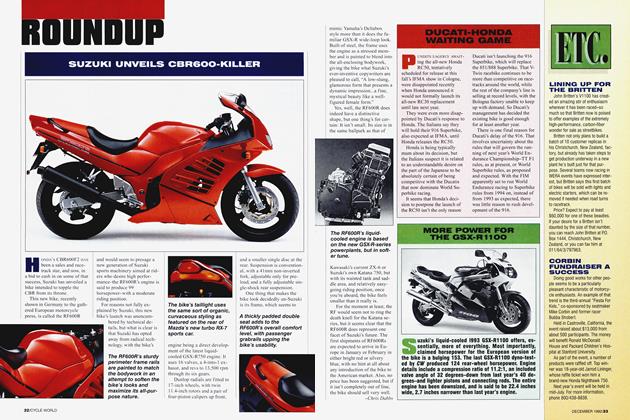

RoundupSuzuki Unveils Cbr600-Killer

December 1992 By Chris Dabbs -

Roundup

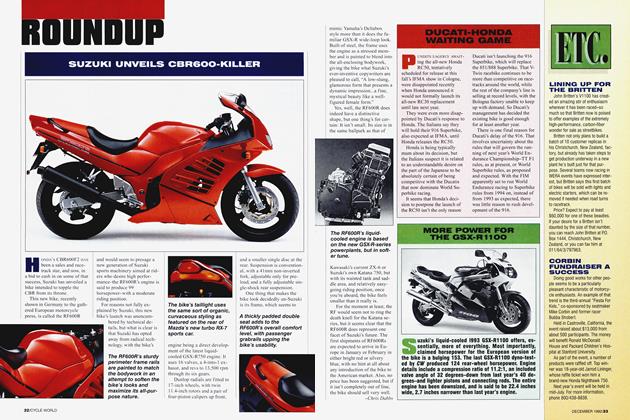

RoundupDucati-Honda Waiting Game

December 1992