FROM STANDARD To SPORTBIKE

CW PROJECT

Not your father’s Nighthawk

BRIAN CATTERSON

WE CAN HEAR THE ACCUSAtions already. In all of motorcycling, there's probably no one group that has made more noise about wanting standard-style motorcycles than the staff of Cycle World, and then the first couple of standards we got our hands on we promptly turned into sportbikes.

Okay, guilty as charged.

In our own defense, however, let us argue that standards like the Honda Nighthawk and Suzuki Bandit (see “Backyard Bandit.“ CW, July. 1991) just beg to be modified. In fact, we became so enthused with the possibilities that we procured two Nighthawks and set about modifying them in different directions. This is the story of how I improved one Nighthawk’s sporting capabilities. Senior Eiditor Ron Griewe's efforts to outfit another for light touring are discussed in the accompanying article.

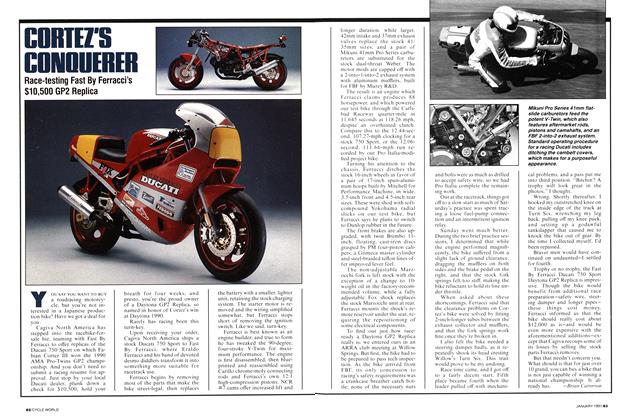

To begin my Nighthawk's transformation. we addressed some of t,he shortcomings of the base model. Principal among these are the rear shocks, which are too harsh on compression and which rebound too quickly. We asked Gil Vaillancourt at Works Performance for a set of his aluminum-bodied Street Trackers, and were impressed with the improvement. Works' shocks are built to order, taking into account rider weight and intended usage, thus they do not have any damping adjustments. What they do have is a wide range of spring adjustments. Preload is adjustable via a threaded collar and the crossover point for the dual-rate springs is adjustable via an option called ARS (for adjustable-rate suspension). With ARS, simply moving a lever to one of four positions changes the spring rate. For most solo riding, we preferred the second-softest position. Works recommends setting preload so that the bike uses onethird of its travel, with the rider onboard, and though that's a bit more sack than we normally like on sporting motorcycles, that figure works well with the dual-rate springs.

Even with the Works shocks installed. our Nighthawk’s compression damping is still too harsh. According to Vaillancourt, the problem is that w ith the Nighthawk's near-1:1 leverage ratio ( 1 inch of shock stroke equals 1 inch of wheel travel), the shocks are required to move so much fluid so quickly that it forces a compromise. Despite being filled with the lightest-weight cartridge fork oil available, the shocks are reluctant to respond to small bumps, and Vaillancourt says that reducing compression damping just makes the shocks bottom too easily over the big stuff. Nevertheless, we feel the improvement in high-speed handling due to increased rebound damping makes the Works shocks worthwhile in vestments.

Our rear suspension woes handled, we turned our attention to the front. The Nighthawk's fork works better than its shocks in stock trim, but there's still room for improvement. Once again, we enlisted the help of Works Performance, which set us up with a set of dual-rate fork springs. Here, a bolt threads into a spacer between the two springs, and the crossover point is determined by the bolt head hitting the cap on the top of the fork tube. Adjusting the crossover point is as easy as turning the bolt, though the springs must first be removed from the fork tubes. As with the shocks, lightweight cartridge fork oil is used, each leg filled to 7 inches from the tube top with the fork compressed and the spring removed. We again set sack to one-third of full travel, and were rewarded with a fork that performed to our highest expectations. While we were at it. we pulled the fork tubes up 1 inch in the triple clamps, which quickened the steering considerably.

Next on the list of the Nighthawk’s weak points are its brakes. Its single front disc and rear drum do a good job of slowing the relatively heavy (501 pounds wet in stock trim) machine to a standstill, but the front brake's feel and the rear brake’s resistance to fading can both be improved. We solved these problems by installing a set of EBC brake pads and shoes, and by replacing the stock rubber front-brake hose with a braidedsteel teflon line from Russell Performance Products.

Though the Nighthawk's stock tires work fine in most situations, for serious corner-carving, a set of sticky sport tires is a must. We upgraded our Nighthawk's traction quotient with a set of Dunlop K591s in the stock sizes, and couldn't be happier.

With the suspension sorted, and braking and traction improved, we figured it would be wise to increase the fork's torsional rigidity. SuperBrace's highly polished aluminum fork brace snapped right on and looks trick, but we're not sure the difference is worth the SI00 asking price. The Nighthawk's 41mm fork is already pretty beefy, and though we did notice improved rigidity under heavy braking and during quick, sideto-side transitions w ith the brace, we also noticed increased fork stiction. as if the brace w'as causing some fork binding. We'd like to see some provision made for fine-tuning the brace’s fit to eliminate that binding.

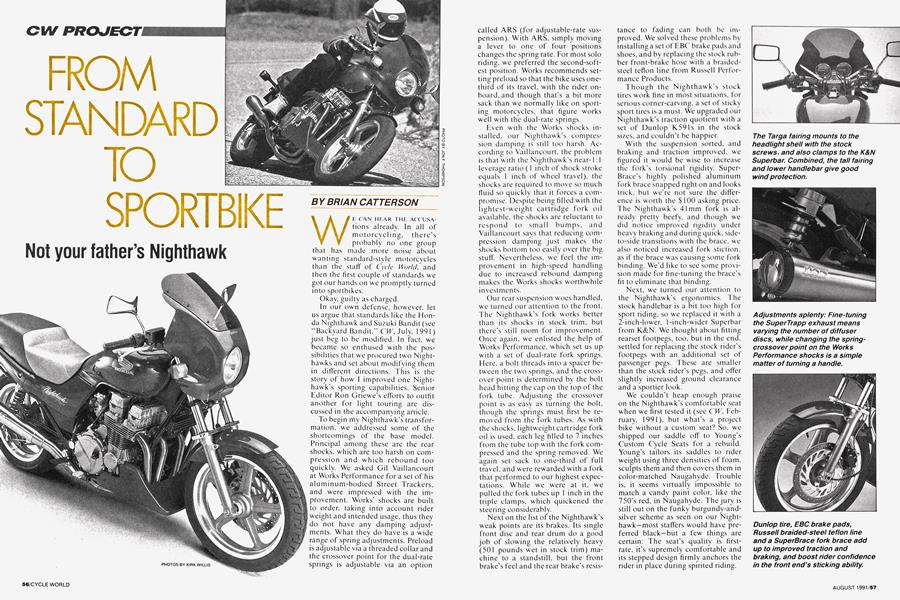

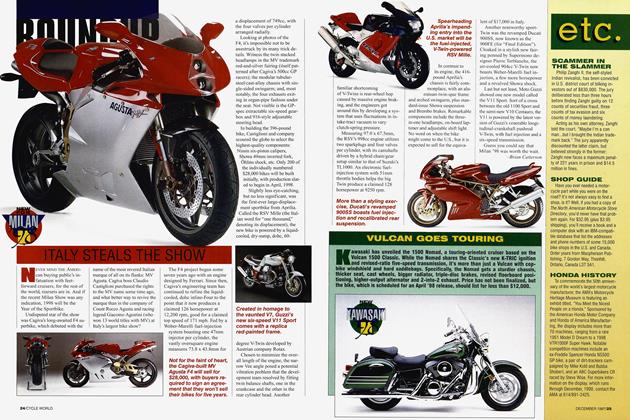

Next, we turned our attention to the Nighthawk's ergonomics. The stock handlebar is a bit too high for sport riding, so we replaced it with a 2-inch-lower, 1-inch-wider Superbar from K&N. We thought about fitting rearset footpegs, too, but in the end, settled for replacing the stock rider’s footpegs wfith an additional set of passenger pegs. These are smaller than the stock rider’s pegs, and offer slightly increased ground clearance and a sportier look.

We couldn't heap enough praise on the Nighthawk’s comfortable seat wdien we first tested it (see Of. February, 1991), but what's a project bike without a custom seat? So, we shipped our saddle off to Young's Custom Cycle Seats for a rebuild. Young’s tailors its saddles to rider weight using three densities of foam, sculpts them and then covers them in color-matched Naugahyde. Trouble is, it seems virtually impossible to match a candy paint color, like the 750’s red. in Naugahyde. The jury is still out on the funky burgundy-andsilver scheme as seen on our Nighthawk—most staffers would have preferred black—but a few things are certain: The seat's quality is firstrate, it's supremely comfortable and its stepped design firmly anchors the rider in place during spirited riding.

Nobody raved about the stock Nighthawk’s, shall we say. less-thansporting appearance, so we enlisted the aid of Targa Accessories, which supplied a fairing and an air dam to help dress up our bike’s looks. The fairing w'orks even better than it looks, offering much-improved wind protection, but the air dam is purely for show, and drew very mixed reactions. Both pieces bolted on with minimal fuss, however, and colormatching is spot-on.

For a finishing touch, we replaced the stock, chromed 4-into-2 exhaust system with a stainless-steel 4-in to-1 from SuperTrapp. Besides looking better, the SuperTrapp weighs a full 20 pounds less than the stocker. In seat-of-the-pants testing, it seemed to boost top-end performance, too, though we did need to fiddle with the pipe and the carburetion first. Varying the number of diffuser discs at the end of the SuperTrapp’s muffler alters backpressure and volume. We first tried it with eight discs, and. though it was quiet, the bike just plain wouldn't run. We then added the remaining six discs, for a total of 14. after which the bike ran rich off' the bottom and a bit lean on top. We turned the fuel-mixture screws threequarters of a turn in and bumped the main jets up two sizes from the stock #1 I 2s to # 1 20s, and the Nighthawk ran great. With the extra discs it's loud, though, something we're not very happy about.

We contemplated further upgrading our Nighthawk's performance— possibly by retrofitting parts from the hotter-performing 1984-86 Nighthawk S—but we'd already added nearly 50 percent to the cost of our $3995 budget standard, so we stopped ourselves in our tracks. Considering that we'd improved our bike's handling, appearance and. to a lesser extent, performance, we figured we’d ride it as-is for awhile before doing anything else. Projects, after all. are never really finished. You just run out of time. And money. E3

SUPPLIERS

American Honda Motor Corp. 1919 Torrance Blvd. Torrance, CA 90501 213/783-2000 Hondaline windshield: $150 Hondaline centerstand: $70

Dunlop Tire Corp. P.O. Box 1109 Buffalo, NY 14240-1109 716/773-8200 110/80V18 front tire: $109 140/70V17 rear tire: $130

Eclipse, Inc. 3771 E. Ellsworth Rd. Ann Arbor, Ml 48108 313/971-5552 Tank bag: $120 Soft luggage: $160

Hy-Tech Motorcycle Components 12860 Bradley Ave. Sylmar, CA 91342 818/362-5534 EBC front brake pads: $26 EBC rear brake shoes: $30

Young’s Custom Cycle Seats 1510 Howe Ave. Sacramento, CA 95825 916/920-3513 Seat: $169

Progressive Suspension 11129 G Ave. Hesperia, CA 92345 619/948-4307 Fork-spring kit: $56 Shock absorbers: $280

Russell Performance Products P.O. Box 6253 Carson, CA 90749 213/602-1202 Brake line: $35 Banjo fitting: $12

Works Performance 8730 Shirley Ave. Northridge, CA 91324 818/701-1010 Fork-spring kit: $70 Shock absorbers: $350

Targa Accessories 23601 A Ridge Route Dr. Laguna Hills, CA 92653 714/472-1022 Fairing: $275 Air dam: $157

K&N Engineering 561 Iowa Ave. Riverside, CA 92502 714/684-9762 Handlebar: $22

SuperBrace 5842 McFadden #0 Huntington Beach, CA 92649 714/894-2994 Fork brace: $100

SuperTrapp 3910 Seaport Blvd. West Sacramento, CA 95691 916/372-5000 Exhaust system: $430

Vance & Hines 14010 Marquardt Santa Fe Springs, CA 90670 213/921-7461 Exhaust system: $259

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSpeed Thrills

August 1991 By David Edwards -

At Large

At LargeStatus Miles

August 1991 By Steven L. Thompson -

Leanings

LeaningsWired

August 1991 By Peter Egan -

Letters

LettersLetters

August 1991 -

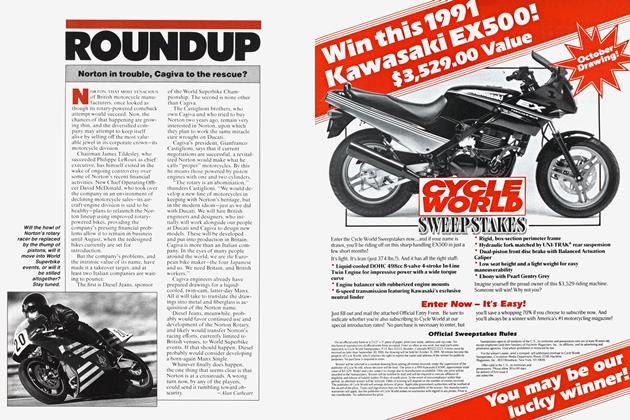

Roundup

RoundupNorton In Trouble, Cagiva To the Rescue?

August 1991 By Alan Cathcart -

Roundup

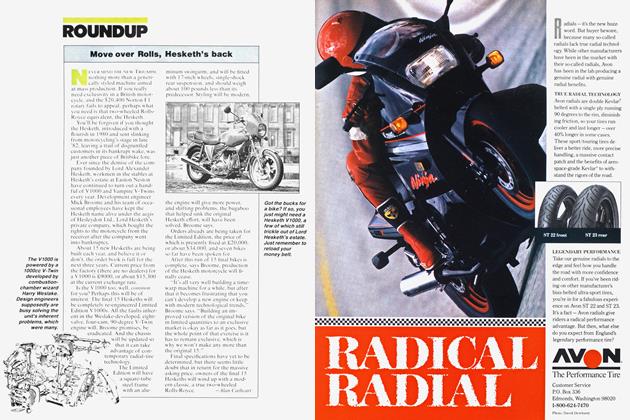

RoundupMove Over Rolls, Hesketh's Back

August 1991 By Alan Cathcart