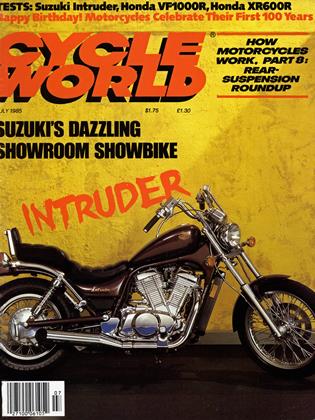

HOW motorcycle WORK 8

REAR SUSPENSIONS

STEVE ANDERSON

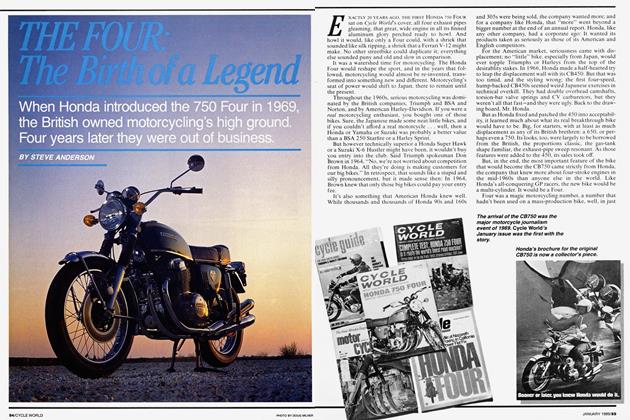

BLAME IT ON MOTOcross. Because before motocross, things were simple. A motorcycle's rear suspension consisted of a swingarm and two shocks, each made up of a simple air/oil damper wrapped with a spring. The rear wheel had from two to four inches of travel, with none of the complexity found in current streetand dirt-bike rear suspensions.

But as motocross became an increasingly popular sport, people soon discovered that the longer the suspension travel, the better the performance. More travel permitted a rider to cross rough terrain at higher speed, and allowed him to survive landings from house-high jumps. And so the suspension race was on.

Getting more front-fork travel was easy—forks merely were made longer—but increasing rear-wheel travel took more thought.

The initial approach was the simple use of longer rear shocks, and the forward positioning of the shock mounting points so that wheel travel could be greater than shock travel. Then came Yamaha’s Monoshock, a triangulated swingarm operating a single shock placed up above the engine, a design that harkened back to the legendary Vincent. That was followed a few years later by Kawasaki’s Uni-Trak, a system of levers and cranks operating a single shock which allowed progressive springing and damping by varying leverage with wheel movement. And when Honda released its Pro-Link suspension, and Suzuki the Full Floater, the dam burst and the motorcycle world was flooded with single-shock dirt bikes.

Streetbikes quickly followed; and now there’s a multitude of single-shock designs offered as alternatives to the classic dual-shock arrangement. So to bring some order out of this multitude, we present the following catalog of rear-suspension designs, complete jj with explanations of their basic principles.

Some of the suspensions shown here date back to cycling’s first days, some to last week. But all help cushion an imperfect world.

Leverage ratio is simply the ratio between wheel movement and shock movement. For a conventional twin-shock suspension with shock mounts near the axle, the ratio is near 1 to 1; for a linkage-type monoshock design, the ratio can be as high as 5 to 1 at the beginning of the travel, and fall to around 2 to 1 when the suspension nears bottoming. Leverage ratio determines the relationship between the effective suspension rate at the wheel (the wheel rate) and the actual rate of the spring. The wheel rate times the leverage ratio squared equals the spring rate. Leverage-ratio and wheel-rate curves for both a conventional twin-shock suspension and a linkage-style single shock are shown in the chart above.

View Full Issue

View Full Issue

More From This Issue

-

Editorial

EditorialSoul-Searching In the Engine Bay

July 1985 By Paul Dean -

At Large

At LargeThe Wrong Bag

July 1985 By Steve Thompson -

Letters

LettersLetters

July 1985 -

Roundup

RoundupMotorcycle Ergonomics: Trouble In the Fitting Room

July 1985 By Steve Anderson -

Roundup

RoundupThe Ultra-High-Performance Yamaha Fz250 Phazer

July 1985 By Koichi Hirose -

Roundup

RoundupThe Striking Yoshimura F1 And F3 Racers

July 1985