HOW motorcycle W.O.R.K 1

THE FOUR-STROKE ENGINE

STEVE ANDERSON

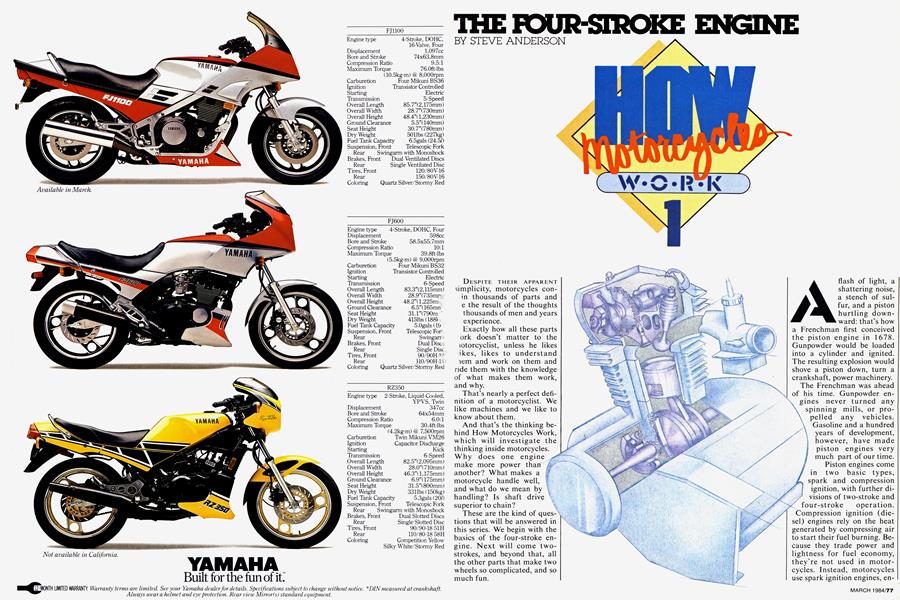

DESPITE THEIR APPARENT simplicity, motorcycles conin thousands of parts and e the result of the thoughts thousands of men and years experience.

Exactly how all these parts ork doesn’t matter to the lotorcyclist, unless he likes ikes, likes to understand them and work on them and ride them with the knowledge of what makes them work, and why.

That’s nearly a perfect definition of a motorcyclist. We like machines and we like to know about them.

And that’s the thinking behind How Motorcycles Work, which will investigate the thinking inside motorcycles. Why does one engine make more power another? What makes a motorcycle handle well, and what do we mean by handling? Is shaft drive superior to chain?

These are the kind of questions that will be answered in this series. We begin with the basics of the four-stroke engine. Next will come twostrokes, and beyond that, all the other parts that make two wheels so complicated, and so much fun.

flash of light, a shattering noise, J a stench of sul fur, and a piston hurtling down ward: that's how a Frenchman first conceived the piston engine in 1678. Gunpowder would be loaded into a cylinder and ignited. The resulting explosion would shove a piston down, turn a crankshaft, power machinery. The Frenchman was ahead of his time. Gunpowder en \ gines never turned any \ spinning mills, or pro \ pelled any vehicles. \ Gasoline and a hundred ,Z \ years of development, however, have made j piston engines very J much part of our time. / Piston engines come J in two basic types, spark and compression /~ ignition, with further di visions of two-stroke and / four-stroke operation. Compression ignition (die sel) engines rely on the heat generated by compressing air to start their fuel burning. Be cause they trade power and lightness for fuel economy, they're not used in motor cycles. Instead, motorcycles use spark ignition engines, engines that light their air-fuel mixture with electric current jumping across an air gap.

Both two and four-stroke spark ignition engines are found in modern motorcycles. The two-stroke crams an entire engine cycle into a single crankshaft revolution, an upand-down piston movement. It’s powerful for its weight and size as a result, and pays a fuel economy penalty as well. Four-stroke engines perform each engine operation in an individual stroke of a piston: the piston descends with an intake valve open, and fresh fuel-air mixture is drawn inside. The valve closes, the piston rises, and the mixture is compressed. A spark jumps across the spark plug’s gap, igniting the mixture, and the piston is forced downward. An exhaust valve opens and the piston rises, forcing the burned remnants from the cylinder. The cycle is ready to begin again.

Intake, compression, combustion, expansion, and exhaust: these are the basic requirements of an engine. These requirements have combined with manufacturing capabilities to shape engine forms. Gas must be compressed and expanded with minimal leakage. The simplest mechanical answer to that has been a piston sliding in a cylinder. A round cylinder and piston can be readily sealed with piston rings, a simple sealing technology developed for steam engines during the 19th century. For power from the piston to be conveniently used, the piston’s straight line motion must be converted into rotation. So the piston is attached to a crankshaft by a connecting rod with pivots at each end; the piston moves up and down while the crankshaft rotates.

Valves are required to control the flow of intake and exhaust, allowing the right gas in or out at the right time, and sealing the cylinder at other times. Every conceivable method of opening and closing a port has been tried at some point: disc valves, drum

valves, slide valves, sleeve valves, piston-controlled valves, poppet valves. Of all these types, only poppet and sleeve valves have been used in large quantities, and the sleeve valve enjoyed only a brief period of popularity for World War II era aircraft engines. The poppet valve has become the answer for flow control in four-stroke engines. Control of valve timing is by a camshaft driven at half crankshaft speed, as each valve, intake or exhaust, only opens once for every two engine revolutions. The cam lobe pushes the valve open (either directly, as in some overhead cam engines, or through a rocker arm or pushrod), and a stiff spring returns the valve from its open position.

The reason behind the parts in a piston engine lie in the behavior of gases, behavior that was understood well before the first four-stroke engine was built. Compress gas and it heats up, expand it and it cools down. Most important, heat a gas (air, for instance) in an enclosed chamber, and its pressure] rises with temperature.

Inside an engine, combustion heats the air trapped in the cylinder. The heat causes the gas temperature and pressure to rise. The increased pressure pushes the piston down, allowing the gas to expand. Energy is passed from the gas to the piston, translated to the mechanical work that pushes on the connecting rod and turns the crankshaft.

Don’t make the mistake the Frenchman made. An explosion isn’t the motivating force in engines. Heat is released during combustion by the controlled burning of an air-fuel mixture. There’s only so much energy to be had from the chemical reaction of fuel and air, and within reasonable limits that amount is independent of burn time. An explosion would just release heat more quickly, exposing the piston and other mechanical parts of the engine to shock waves that strip away insulating boundary layers of gas, overheating the parts. Damage done with no gain in power.

For an engine to operate, specialized systems are required to work with the basic piston, cylinder, valves, and crank. Carburetion or fuel injection has the task of supplying fuel and air in the range of mixtures the engine will tolerate. Engines are finicky; too much gas and too little air, and a spark won’t start the fire burning. Too little gas and the problem reoccurs. If the engine is expected to do more than run, and must make the most power or make the most efficient use of its fuel, the range of acceptable mixtures will be narrower yet. Modern carburetors are sophisticated instruments for rationing the proper amount of fuel for the air flowing through, but even so, they’re losing ground to electronic fuel injection systems that offer the promise of more precise control.

The ignition system’s job is to start the fire burning in an engine at the right time. The ignition stores electrical energy in a coil or capacitor, and dumps the energy to a spark plug when signalled. The result is a spark jumping across the plug’s gap, and the start of combustion.

A lubrication system is required to supply oil to all the moving joints and surfaces in a piston engine. On low speed, low power engines, this can be as simple as a slinger on the crankshaft that dips into an oil reservoir each engine revolution, splashing oil with the knowledge that some will reach critical bearings. Or it can be as complicated as in a Formula One car engine, with separate pressure pumps for crankshaft bearings and cylinder head lubrication, and huge scavenging pumps sucking excess oil away from rapidly spinning parts. Motorcycle engines fall between these extremes, and usually have one pressure pump supplying oil to crank, connecting rod, and cam bearings. If gravity returns the oil to a reservoir at the bottom of the engine, the lube sytem is known as a wet sump system. If the oil is pumped from the bottom of the engine to a remote reservoir, it’s a dry sump engine.

A cooling system is required to take heat away from mechanical parts exposed to hot gas. Motorcycle engines long depended on air flowing past cooling fins for heat removal, while car engines have transferred the heat first to a water jacket surrounding the cylinders and combustion chambers, and then to the air via a radiator. Air-cooling offers simplicity in operation, while water-cooling offers simplicity in design because it more thoroughly evens out temperature differences within the engine structure. There are arguments to be made for both cooling systems, and it’s likely we’ll continue to see both used on motorcycles.

However many systems are needed, an engine is expected to do more than run. It must make good power for its weight or displacement while offering reasonable fuel economy. The heart of good engine performance is the combustion chamber. A look at its evolution illustrates the critical issues in four-stroke engine design.

In early engines, when making any power at all was a useful achievement, mechanical simplicity dictated design. The intake and exhaust valve were placed next to the cylinder, the valve heads up and the stems down. The combustion chamber extended out from the cylinder, overlapping the valves. The cam drive was simple, with the cam near the crank, and the valves were very directly actuated by the cam. An engine of this design was known as a side-valve, and offered a measure of mechanical reliability in an age when that was a major advance. What the side-valve didn’t offer was power or economy.

The side-valve had problems. Compression was low and flow through the valves was limited at high engine speeds.

Compression is usually expressed as the compression ratio, the ratio between the volume above the piston when it’s at the bottom of its stroke and the volume above the piston when it’s at the top. With a compression ratio of 9:1, the mixture is squeezed into one ninth of its original volume at the top of the compression stroke. Compression is an important contributor to power ; and efficiency not in itself,but because the amount of compression is also the amount of expansion on the power stroke. The compression ratio is the expansion ratio. The hot high pressure gas trapped in the cylinder after combustion expands to fill the cylinder volume as the piston descends. The greater this expansion, the lower the final gas pressure when the exhaust valve opens, and the more work taken from the gas. With a low compression ratio, expansion is incomplete, and the exhaust valve opens with high pressure gas in the cylinder. Potential power is wasted out the exhaust.

Compression is limited in the side-valve engine by the pocket that had to be left above the valves, and by detonation, the explosive combustion of mixture in the engine. Detonation occurs like this: a flame starts at the spark plug normally enough, and burns across the combustion chamber. As it travels, heat is added to the chamber, and mixture temperature and pressure increase. Sometimes the pressure and temperature increase to the gasoline’s auto-ignition condition, the point where air and gasoline ignite without a flame. Ping! All the unburned fuel and air in front of the flame front explodes at once, sending shock waves ricocheting about. Detonation is linked to compression ratio because the higher the compression, the higher the initial temperature of the mixture when combustion starts, and the closer conditions are to those that cause auto-ignition.

Early examples of the sidevalve engine had a combustion chamber extended over the entire cylinder bore, and this proved horrible for detonation resistance. A partial fix for this was a combustion chamber concentrated over the valve pocket and only part of the piston, with a broad squish area over the rest of the piston. The chemical reactions that precede auto-ignition and detonation aren’t instantaneous; they take a certain length of time. By speeding up the combustion process with a more compact chamber, the flame front can outrace chemistry, and normal non-explosive combustion can take place. The modified, compact, side-valve chamber allowed compression ratio to be raised by several points, and improved power and economy.

This approach can only be carried so far in the side-valve engine. A compact side-valve chamber is in direct opposition to what is required for flow through the valves. For high flow rates, the valves have to be large, and the pocket above the valves have to be large to stay out of the way of the valve head and the flow. The side-valve is stuck in a compromise: a good

combustion chamber for burning, or a good chamber for flow, but not both at the same time.

A reaction to this is the intake-over-exhaust (IOE) design, but it’s only a partial solution. Move the intake valve directly over the piston and there’s better flow through the intake valve with slight improvement in the combustion chamber shape. This makes intake valve opening more complicated, requiring a pushrod and rocker arm.

Put both valves over the piston and you solve more problems. This is the overhead valve design, used one way or another in all current fourstroke motorcycles. It offers almost complete freedom of combustion chamber shape and allows large valves with plenty of room around the valves for good air flow. Compression can be high and with the good air flow, good power can be made.

The overhead valve combustion chamber has relegated other designs to use only in the meanest industrial engines where initial cost far outweighs performance. (Note that an ohv engine is any engine that has the valves above the piston, not just an engine with pushrods. It’s convenient to classify engines by the number and position of camshafts, but if you had a piston’s eye view, you could see that a Triumph Twin, a Honda CBX and a Yamaha TT500 all use ohv combustion chambers.) The questions now become, Where to put the cam and how many valves should each cylinder have?

The amount of power required from an engine determines almost everything about it. Think of an engine as a positive displacement pump, a fancy air mover. The more air pumped through, the more fuel that can be burned and the more heat that can be turned to mechanical power. Air volume through an engine is power. So how do you force more air through? One fourstroke cycle pumps the engine’s displacement, the difference in cylinder volume between the piston at the bottom and top of its stroke. More air pumped in a given time requires either more displacement or more cycles. The designer has a choice: a bigger engine or a faster turning one.

Which to choose isn’t always obvious unless competition rulebooks or the marketplace dictate an engine to be a certain size and no bigger. Then, more power must be obtained from higher engine speeds. That statement sums up the entire Honda GP effort of the 1960s: ever increasing rpm, and ever increasing power.

I There are limits. Higher engine speeds increase the load on engine components, so the engine can only be turned as fast as the weakest or most heavily loaded parts will stand. Generally those parts will be the reciprocating ones, the ones that reverse their straight line movement with each crank revolution: the pistons and rings, or the valves and valve springs. The load on the piston and rings increases with engine speed and with the stroke length, the distance the piston has to travel up and down each revolution. The load on the valves increases with speed and valve weight. If a particular displacement came from a big bore and a short stroke, the piston doesn’t move as far for any given number of revolutions compared to the piston in an engine of the same displacement arrived at from a small bore and a long stroke. The piston in the short stroke engine has an easier life, and can survive higher rpm than its long stroke peer. (Because of the importance of bore/ stroke ratio, engines are classified by it. An engine with equal bore and stroke dimensions is known as square. An engine with a larger bore than stroke is oversquare, and a long stroke engine is undersquare.)

The oversquare engine may favor its pistons, but not its valves. The higher speeds require more valve area to flow the increased amount of air, and more valve area requires larger, heavier valves. The weight of the valve and the parts linking it to the cam impose limitations on how quickly the valve can open and close: if the cam opens the valve too quickly, the valve may overshoot the full open position and float off the cam. Then the spring will ram the valve back into contact with the cam, abusing the machinery. A stiffer valve spring will delay the onset of valve float, but at a cost. The loads at the cam face and on the valve will be greater, giving more friction and wear. A compromise is required between engine speed, spring stiffness, and valve train weight.

So an engine can be made oversquare to the point where the speed limiter is the valve gear instead of the pistons. How do you further increase engine speed? Make the engine more oversquare yet, and use four small valves instead of two large ones. The four small valves can flow as much or more air, and, more important, they can live at higher speeds. Even then there’s a limit to how oversquare an engine can be: a 1.5:1 bore to stroke ratio seems to be the current balance between piston and valve train stresses in four valve engines. If more power is desired after that, the engine’s displacement must be divided among more cylinders.

The secret is that the amount of air that can be pumped, and therefore power, is directly proportional to piston area. Or, put another way,

parts that have to move a short distance can do it more quickly than parts that have to move a long distance, and small valves can move more quickly than big valves. Stroke differences have almost no effect on power if piston area remains the same. A larger displacement version of an engine created by lengthening stroke is limited in speed by its new stroke, and its extra displacement is exactly compensated by its lower speed capability. (This refers to engines optimized for their stroke length and operating at the same piston stresses. These conditions are not always true of stroked and hopped up versions of production engines, which is why stroke changes may work as a hot rodding technique.) For the most power from a given displacement, stroke length must be kept to a minimum and piston area enlarged accordingly. Such an engine will be as oversquare as feasible, and have as many cylinders as economics or the rule book will allow.

That’s the design that displacement restrictions demand. What if there were some other constraint, say, for maximum fuel efficiency? That requirement might lead to a slow-turning, long-stroke design, an engine with piston area limited to minimize heat losses and speeds held low to keep engine friction low. Other constraints would lead to other designs. A grand prix formula of the 1930s required only that a car and its engine weigh less than 750 kg, and that led to large displacement, relatively slow turning engines designed for minimum weight for their power. Before we decide one engine design is best, it’s necessary to specify exactly what it’s best for.

The same might be said for combustion chamber designs. There’s no single answer, but rather a spectrum of ohv variations depending on other engine characteristics. For all-out racing engines, the answer has been four valves in each cylinder, a pair of intakes and a pair of exhausts, each pair leaned 12 to 20 degrees outward from the cylinder centerline. The piston is flat-topped, and the spark plug is centrally located. The advantages are the high engine speeds allowed, and the high compression ratios permitted by good combustion. This configuration has been carried over to many motorcycle engines, but with modifications. Motorcycle intake ports often have a bend in them to allow side-draft carbs, and air-cooled engines often have their valves splayed at a wider angle. It’s difficult for cooling air to reach the top of the cylinder head if it’s totally obscured by close-set cams, so combustion chamber shape maybe compromised for cooling need.

Another configuration is becoming standard for engines that aren’t required to be the most powerful in their displacement class. Two valves are inclined 40 to 60 degrees from each other in a chamber that’s a section of a sphere. The piston is flat topped. Intake swirl may be increased by an offset of the intake valve or port, or perhaps two spark plugs are used to speed up combustion. This type of chamber can offer good combustion and economy, and good if not ultimate power.

There are other alternatives as well, each with its advantages and disadvantages. Honda plays around with three-valve chambers, and cylinder heads that have four valves all splayed out radially, perpendicular to the surface of a sphere. Moto Morini and Moto Guzzi have engines with flat cylinder heads and valves set flush with the head surface; the combustion chamber is a depression in the top of a piston. There is no perfect combustion chamber. Some are better than others, though, and companies may test hundreds of configurations in single cylinder lab engines before making a production decision.

How valves are operated depends on which design goals are given priority. Where the need for power is foremost, the fewest parts are imposed between cam lobe and valve. The cam lobe can’t push directly on the valve stem; that would result in side loads on the valve that would wear out the valve guide. Instead the cam must push on a tappet or rocker arm that ensures that the valve loading is essentially straight line. The lightest valve train for a combustion chamber with inclined valves comes with two camshafts sitting directly above the valves, with only rockers or tappets interposed between cam lobe and valve. This is known as a double overhead cam, or dohc, configuration. It’s used in almost every racing engine designed for the highest power from its displacement.

A less expensive alternative is a single camshaft in the cylinder head operating inclined valves through rocker arms. (In automotive applications, a single cam sometimes operates a row of valves directly through tappets, but this combustion chamber design is too much of a compromise for most motorcycle applications.) This would be described as a single overhead cam, or sohc, design. It gives slightly more valve train weight than a dohc configuration, imposes more restrictions on where the valves and spark plug can be located, and is difficult to use on four-valve heads on engines that have more than two cylinders. Still, it’s a reasonable compromise between overall engine weight, power, and cost.

Another option is to mount the camshaft below the head, close to the crank, and open valves through pushrods and rocker arms. This might be described as a pushrod valve system, or simply as overheadvalve (ohv). The cam drive is simplified at the cost of increased valve train weight. Not the sort of compromise to make for an ultimate performance engine, and it’s not any cheaper to make than a sohc setup except in V-engines, where one set of cam lobes can operate two sets of valves through pushrods. It may also make an engine shorter or lighter than an overhead cam alternative.

Efficiency is one consideration ignored so far in this discussion of engines as air pumps. Every engine of the same displacement peaking at a certain speed doesn’t make the same power. This may be because one engine may be less successful than another in charging its cylinders with air/fuel mix. Or it may be because it has higher internal friction losses, or because a poorly designed combustion chamber requires an engine to run less compression than its peers. Whatever the reason, the efficiency of an engine can be expressed in its brake mean effective pressure (bmep). This is the average pressure that would have to exist in the cylinder during the expansion stroke for the engine to make the power it does. Power divided by engine speed, engine displacement, and a constant equals bmep. Bmep is a theoretical number that combines all engine deficits and strengths in a single index, and doesn’t give the actual pressures that exist in the cylinder. Its usefulness is in making comparisons between engines of different sizes peaking at different speeds. The higher the bmep, the more power an engine makes for its size and speed.

Similar engines have similar bmeps. That’s because of development and competition, and because no company ignores the progress made by others. Japanese four-stroke street bike engines range in the 145 to 165 psi area. Racing four-strokes give higher numbers, typically from 180 to over 200 psi. Looking at the bmep figure at peak power is interesting because it gives an indication of how well the engine designer did his job, or perhaps how highly tuned the engine is. (Higher bmep figures at peak power may come from trading power band width for peak power.) And they’re also interesting because they allow predictions to be made about yet unbuilt engines. A Honda engineer has claimed that by the mid1980s, Honda will be producing a normally aspirated four-stroke street bike putting out 200 bhp per liter of displacement. Assuming its bmep were in the current high range for street bikes, 165 psi, such a bike would have to peak at 16,000 rpm.

The four-stroke piston engine has existed in more-orless its present form for 100 years. During that time, it has evolved from a large stationary engine making 3 bhp from 6100cc to the point where 50cc pedal bike engines make more power than that. The progress continues. Ten years from now, four-stroke evolution may produce motorcycles as amazingly powerful as current models would have been in 1974.

View Full Issue

View Full Issue

More From This Issue

-

Departments

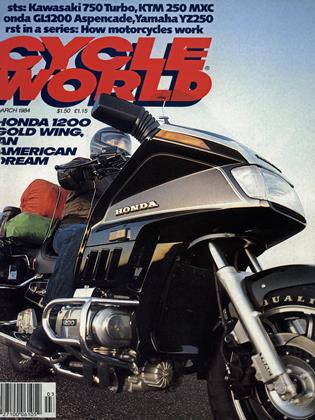

DepartmentsCycle World Up Front

March 1984 By Allan Girdler -

Cycle World Letters

Cycle World LettersCycle World Letters

March 1984 -

Technical

TechnicalCycle World Follow Up

March 1984 -

Departments

DepartmentsCycle World Round Up

March 1984 -

Competition

CompetitionIt's Okay, We're With the Duck

March 1984 By Allan Girdler -

Technical

TechnicalPainting Plastic

March 1984