HOW MOTORCYCLES W·O·R·K 5

FINAL DRIVES

STEVE ANDERSON

"Shafts suck! They're heavy and they make the bike go up and down like an elevator." "No, I think you've got that back-wards— chains are the worst. They leave a greasy stripe down the back of your jacket, and they always seem to need lubrication or adjustment or replacement or something.”

“As far as I’m concerned, you’re both right. Belts are the way to go. My Harley Sturgis doesn’t do any of those things, and in 30,000 miles I’ve only had to adjust the belt once.

Truth is, not one of these three bench-racers is completely right or completely wrong. They’ve merely gotten into one of those barroom arguments that produce more heat than conclusions, that depend more on prejudice and preference than on fact.

Twenty years ago, there wasn’t as much to discuss on the subject of final drives. There were BMWs with shaft drive, and there was everything else with chains. But now, more new motorcycles than not use shafts, and bikes can almost be classified by the type of final drive they use. A chain-driven bike is probably a hard-core sport machine or a dirt bike; a shaft-driven one is most likely a touring bike or a cruiser; and if it uses a belt, it’s either a Harley-Davidson or a Kawasaki commuter bike.

All of these final-drive systems serve the same purpose, though, which is to take the power from the gearbox output and use it to drive the rear wheel. But each one accomplishes that job in a different way. A chain, for example, transmits power from gearbox to rear wheel by pulling. A sprocket on the gearbox pulls on the chain, which in turn pulls on a sprocket attached to the rear wheel. The result is wheel rotation. Only the top run of the chain is under tension when the engine is driving the rear wheel; the bottom run serves only to return the chain to the gearbox sprocket so it can repeat the process. But when the rear wheel is driving the engine, which occurs any time the throttle is closed while the bike is moving, it’s the rearwheel sprocket that pulls on the chain, which in turn pulls on the gearbox sprocket, and so only the bottom run is under tension.

Chains must engage with the sprocket teeth in a solid, positive manner, but they also have to be flexible enough to wrap around the sprockets. It’s almost a contradictory task, to be both rigid and flexible at the same time, and a chain accomplishes this by being made up of many rigid individual segments connected by pinned joints. Each segment is called a link, and there are two types: roller links and pin links.

A roller link is comprised of two parallel sideplates connected by two bushings (see Fig. 1). Riding rather loosely around each bushing is a roller, which is the part that actually comes in contact with the sprocket teeth. The pin links tie the individual roller links together to form a complete chain. The sideplates of a pin link span the distance between two adjacent roller links, and its pins fit through holes in the sideplates and in the roller-link bushings. The pins are a press-fit in the pin links, but there is enough clearance between the bushings and pins to allow the roller links to rotate.

Most of the rotation between the links of a chain happens when the chain wraps around the curvature of a sprocket. The motion of the chain onto the sprocket isn’t entirely smooth, because the chain consists of short, straight sections connected by joints and thus cannot deform into a true curve. There is, then, a mismatch (see Fig. 2) between the curvature of the sprocket and the polygonal shape the chain forms as it wraps around the sprocket. The mismatch varies according to the position of the sprocket teeth, and that variation results in a slight up-anddown vibration imparted to the chain—in addition to causing minute variations chain speed as the sprocket rotates. There’s enough flexibility in a chain to absorb the speed differences, but the vibration can accelerate wear. These effects are known as chordal action.

Toothed belts are, in many ways, similar to chains. Both drive the rear wheel by pulling on a sprocket, and both have provisions to allow positive engagement on the sprocket (the rollers on a chain, the teeth on a belt) so there is no slippage. The major difference between the two types is the increased flexibility of the belt. Unlike chain, a belt isn’t a collection of rigid segments connected by flexible joints; instead, it’s almost one big flexible joint. A belt forms a true radius around a sprocket, and so there’s no chordal action there is with a chain.

Drive belts are a sophisticated composite of fiber and rubber. The fibers wrapped around the circumference the belt take the tensile loads, and the fabric facing the inside helps preserve the tooth form. The rubber is there mainly to hold the fibers together, and to transmit loads from the tooth area to the outer fibers. Toothed belts have been around for years, but only recently have material improvements allowed belts that can deal with the levels of power put out by motorcycle engines. So while industrial belts are made of nitrile rubber and fiberglass, motorcycle belts are of polyurethane, Kevlar and nylon.

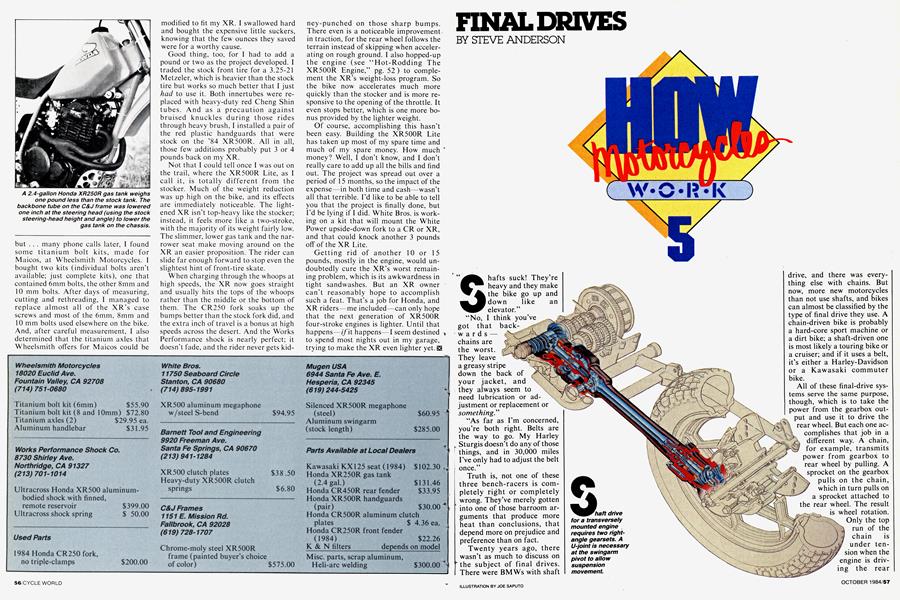

Shaft drives are fundamentally different than either belts or chains in the way they take power from the gearbox to the rear wheel. Instead having a chain pulling on sprockets, a shaft-drive uses rotating rod or tube (the actual driveshaft) between the gearbox and rear wheel. The driveshaft terminates with right-angle gear that drives mating gear attached to the rear wheel.

Shafts are a natural means of final drive on bikes like BMWs or Gold Wings that have their crankshafts running fore-and-aft in the chassis; on these motorcycles, the gearbox output shaft is already facing in the proper direction, parallel to the driveshaft. On motorcycles with 'across-the-frame crankshafts, such as transverse-Fours, the gearbox output shaft also runs side-to-side; and so a second right-angle gearset, usually at the gearbox output shaft, is required to turn the power rflow 90 degrees and aim it in the same direction as the driveshaft.

Because the rear suspension must move up-and-down, however, a driveshaft can’t be a single piece running between gearbox and rear wheel; that would prevent the swingarm from moving. But a universal joint placed in the shaft—ideally, right at the swingarm pivot—allows the necessary flexibility. If the universal joint can’t be positioned precisely at the swingarm pivot, suspension movement will cause the effective driveshaft length to vary as the rear wheel moves up and down; and in that case, a splined slip-joint must be 'provided somewhere along the shaft.

Another way of comparing shafts, chains and belts as final-drive mediums is in terms of efficiency. But that’s a tough comparison to make with any degree of accuracy. Engineering handbooks indif cate that roller chains, for instance, transmit power with 98 to 99 percent efficiency. In other words, if there is 100 horsepower available at the countershaft sprocket, between 98 and 99 of it would reach the rear wheel. The rest would be turned into heat by friction in the chain links and between the chain and sprockets.

Handbook numbers, however, are based on ideal industrial conditions, with smaller loads and better lubrication than what a chain must endure on the average motorcycle. People who do dyno testing with chain-driven motorcycles report much higher losses. Honda engineers estimate that only around 93 percent of the power passing through the countershaft sprocket arrives at the rear wheel, and Kawasaki racebike tuners say that 5 of a KR250 Twin’s 60 horsepower can disappear into the chain.

Understand, of course, that chain-drive power-losses are largely a function of chain condition and, perhaps more important, chain lubrication. In some cases, a poorly lubricated chain can consume twice as much power as a properly lubricated one.

Establishing an efficiency rating for shdft drives is even more difficult. Consider, for example, the circuitous path that the power must take when exiting a transversely mounted engine with shaft drive—say, a Honda 650 Nighthawk. After leaving the transmission, the power has to pass through a right-angle spiral-bevel gearset, through a U-joint, down the driveshaft and through yet another right-angle spiral-bevel gearset. Surprisingly, major power losses do not occur in the gearsets, because spiral-bevel gears of this sort typically operate with 99 percent efficiency when tested in ways that minimize the effects of their lubrication system and support bearings.

That, however, is the rub, because lubrication and support certainly are necessary when these gearsets are used on a motorcycle. And the friction caused by oil pumping in and out of the meshing gears, and through the support bearings, as well, can result in horsepower losses several times larger than those in the gears themselves. An estimate of the overall efficiency of shaft final drive, then, would put it in the same 90-to-96percent range as chain drive, with the actual efficiency of any system being very dependent on its particular design.

If shafts and chains have more-or-less achieved parity in terms of overall efficiency, toothed belts have clearly pulled into the lead. Extensive industrial testing of belts has shown efficiencies in the 98to-99-percent range; and, unlike the situation that exists with roller chains, there is no reason to suspect that these efficiencies cannot be achieved in the environment presented by a motorcycle.

But while high efficiencies are desirable (why bother designing a super-potent engine just to throw away 7 percent of its power on the way to the> rear wheel?), efficiency still remains a theoretical concern rather than a practical one. More important when it comes to actually living with a final-drive system are reliability and maintenance. And it is in these areas where you find the most dramatic differences between types of final drive, with shafts holding the advantage. A shaft drive is an enclosed system, with its gears and bearings and lubrication hidden out of harm’s way inside sealed housings. There’s no contamination from the outside and no reason why the components can’t outlive the engine and gearbox to which they’re connected. And in practice, that’s generally the case, with shaft drives requirr ing no more maintenance than the occasional topping-up of the oil in the drive housing.

Chains are far more demanding. A conventional roller chain wants to be lubricated every few hundred miles, has to be adjusted alrmost as frequently, and has a useful life measured in the low thousands of miles. These characteristics result from the hundred or so pin-joints that give the chain its flexibility. When the gears of a shaft ■ drive wear slightly, the only result is an equally slight increase in driveline backlash; but when the pin joints of a chain wear—which they do at a high rate—the effect is multiplied by the number of joints in the chain. The slight wear at each joint translates into a substantial increase in overall chain length, and a slack chain. Joint wear also increases the effective chain pitch enough to cause a mis. match between the chain rollers and the sprocket teeth, thereby concentrating the loads and accelerating sprocket wear.

To minimize chain wear, a plentiful supply of lubrication is required in the pin/bushing joints. But unfortunately, the typical motorcycle chain has to survive on the lubrication provided by its most recent oiling; and that oil is easily washed away by rain or contaminated with gritty dirt and dust.

That problem, along with the outrageous power outputs of bikes built in the last decade or so, created a demand for better drive chains. One approach was to make the chains used on high-powered bikes larger, going from 5/sinch pitch (50-series chain) to 3/4-inch pitch (60-series chain). That helped durability, but it didn’t address the problem of chain lubrication. These high-performance motorcycles would make their chains so hot that the grease in the pin/bushing joint would liquefy and flow out, eventually leaving the joint dry. One solution was the sinteredbushing chain. The bushing on each roller link was made oversize and from a porous material so it could be impregnated with grease and act as its own lubrication reservoir. This design dispensed with rollers altogether, and demonstrated that rollers weren’t actually mandatory for adequate chain and sprocket life.

Sintered-bushing chains have been standard fare on big-bore roadracers for a decade, but they still have the same basic problem as standard chains: The grease supply is finite and the chain loses grease at a fairly quick rate. A good solution came with the advent of the O-ring chain, which is the longest-lasting of any chain other than one that runs in an enclosure. The Oring chain has increased clearance between the sideplates of its roller links and the sideplates of its pin links, which leaves room for the Orings themselves. The O-rings seal grease in the pin/bushing joint, and seal water and grit out. And that, along with improved materials and greases, allows chains that will last 10,000 miles or more on the most powerful performance bikes while requiring only occasional

"These high-performance motorcycles would make their chains so hot that the grease in the pin/bushing joint would liquefy and flow out, eventually leaving the joint dry."

About the only variation of chain drive that offers longer service life and less maintenance is the type that seals the chain in an enclosure and bathes it in lubricating oil. Such chain enclosures have been used on-and-off throughout motorcycle history, and they’ve always resulted in improved chain life. The only motorcycle currently sold in the U.S. with an enclosed chain is Harley-Davidson’s FLT touring bike, and many owners of that model report chain life of 20,000 miles or more. A final-drive system that used the highest-quality No. 630 chain running in an enclosed oil bath could offer chain life equalling engine life, while requiring chain adjustment no more often than valve adjustment. Unfortunately, enclosed chains look rather bulky and unattractive, so they haven’t proven very popular with the public.

Belt drive doesn’t quite match shaft drive for minimal maintenance, but it isn’t far behind. No lubrication is required with a belt, and adjustments are infrequent, usually 10,000 miles or so apart. Belt life seems exceptional, at least on the H-D Sturgis, and Harley dealers report some instances of more than 50,000 miles on a single belt.

So on motorcycles where reliability and convenience are paramount, shaft drive is the obvious choice. That largely explains why shafts are preferred on touring bikes and cruisers. For one thing, weight is an important consideration on a sport machine, and shaft drives, with all of their gears and joints and bearings, are heavy; and much of that added weight is unsprung, which can have adverse effects on tire adhesion in bumpy corners. Consequently, most sportbike riders seem willing to put up with the inconveniences of chain drive to get the added measure of performance it provides.

Interestingly enough, belt drive is lighter still, yet it hasn’t found a home on highperformance streetbikes. That’s because overall size is also an important consideration when a designer is choosing a final-drive type. Even though shafts are quite heavy, they’re also very compact, which leaves plenty of room for the exhaust pipes to tuck up closely to the swingarm for increased cornering clearance. Both shafts and chains can be fairly narrow, as well, but belt drives tend to be wide. The belt drive on Kawasaki’s KZ440, for example, takes up considerably more room than the chain system used on the chain-drive version of the same motorcycle. Not only is the KZ’s belt a quarter-inch wider than a No. 530 chain, it also runs on considerably larger sprockets, which reduces the load on the belt by giving it more leverage, just as a longer wrench gives more leverage on a bolt. Without the large sprockets, the belt would have to be wider still.

Their bulkiness will probably limit the use of belt drives either to low-powered motorcycles, or to bikes that allow plenty of room for a wide belt. The KZ440 belt and sprockets that transmit about 35 horsepower are less compact than the No. 530 chain and sprockets that deliver around 100 horsepower on a Honda 1000 Interceptor. The belt drive on the 60-horsepower Harleys Sturgis is 1.5 inches wide and uses a rear sprocket a foot in diameter. Scale that up to Suzuki GS1150 proportions and the belt would have to be about 3 inches wide, and the countershaft sprocket would be big enough to hit the swingarm pivot. Performance' bikes are becoming narrower for better cornering clearance, and their rear tires are becoming wider; as a result, finding the room to fit a drive belt will be difficult, if not altogether impossible.

All current final drives interact with the rear suspension, more often than not to ill effect. During acceleration, more weight is supported by the rear wheel than when the bike isn’t accelerating. That’s^ the normal weight-transfer. If the additional load is transmitted to the rear wheel by the suspension, the rear of the bike will squat to some extent. But the rear wheel also can be loaded by the interaction of the swingarm and the final4 drive rather than by the suspension, in which case the back of the bike might stay level or even rise. Such a bike would be said to have antisquat tendencies. If the bike stayed completely level during ^ acceleration, it would have>l 100 percent anti-squat; if the back end rose during acceleration, the bike would have more than 100 percent antisquat.

The ideal amount of antisquat for a motorcycle rear suspension is a matter of debate, but it’s somewhere in the 0-to-100-percent range. The extreme amounts of antisquat provided by shaft-drive motorcycles lead to excessive pitching of the chassis and too much time spent with the rear suspension topped-out and effectively rigid. Some manufacturers attempt to compensate for the pitching by reducing the rear-suspension travel, increasing the damping and upping the spring rates, but all these measures also have an effect on the suspension’s overall effectiveness.

A shaft drive’s anti-squat forces are a direct result of Newton’s second law: For every action there is an equal and opposite reaction. As the pinion in the rear gearcase of a shaft-drive motorcycle tries to drive its mating ring gear on the rear wheel, an equal force is exerted in the opposite direction on the gearcase. But, since the gearcase is bolted solidly to the swingarm, it can rotate only by rotating the entire swingarm about the rear axle in the opposite direction of tire rotation. When that happens, the entire motorcycle is lifted simply because the front of the swingarm is attached to the frame at the swingarm pivot.

The magnitude of this lifting force can be amazing— enough, sometimes, to effectively lock the rear suspension solid. The force is proportional to the torque driving the rear wheel, so it’s greatest in the lower gears, where the torque-multiplication is greater. The amount of lift decreases with any increase in swingarm length (a longer swingarm has less leverage on the chassis), so short swingarms yield increased anti-squat.

Chain and belt drives also generate anti-squat forces in most cases, but not to the same degree as shaft drives. The typical chain/belt-driven streetbike falls in the 0-to-100 range of anti-squat, so the effect on the rear suspension is less noticeable than with shaft drive. The amount of antisquat depends on the relationship of the top run of the chain to the swingarm pivot: The further above the pivot the chain is at any given time, the lower the amount of antisquat.

These easier-to-manage suspension interactions, along with the lighter weight and ease of gear-ratio changes, explain why chains predominate on racebikes and sport machines. With the standard shaft-drive configuration, it’s impossible to avoid the kinds of suspension compromises that are not conducive to optimum handling—although BMW’s new K100 demonstrates that it is possible to have shaft drive and a suspend sion that works quite well for sport riding.

It is possible, though, to reduce or eliminate a shaftdrive’s severe anti-squat effects by floating the rear gearcase just like on a full-» floating rear brake. Instead of being bolted directly to the swingarm, the case can be al-> lowed to rotate about the axle, with the rotation controlled by a link running parallel to the swingarm. This would effectively remove the gearcase’ from the swingarm, and in doing so, eliminate the antisquat altogether. The drawback is that this system requires another universal joint on the driveshaft as well as additional pivots for thev torque link, all of which increases weight and complexity. But this concept has been used before (a 1950s MV Agusta 500cc GP roadracer and BMW’s Futuro showbike), and it might bev seen again in the not-so-distant future.

But as far as the final-drive’ systems of today are concerned, it seems that most motorcycles have the drive system that best serves their needs. Sportbikes and dirt bikes use chains because the'» weight and the suspension effects of a shaft are unacceptable for their purposes. Tour-1 ing bikes and cruisers use shaft drive because minimal maintenance has a higher priority than handling or un-4 sprung weight. And belts simply are too bulky for most motorcycles, although they might be used more often in the future on smaller bikes of all kinds, and even on large touring machines where size* isn’t such a concern.

Yet there is room for development. Floating the reargearcase on shaft drives could eliminate the undesirable anti-squat effects, and using enclosures and oiling systems^ on chain drives could minimize chain wear and adjustments. With those kinds of, improvements, final drives wouldn’t be so stereotyped according to performance. But even if that were to happen, bench-racers would continue'*« to argue about them anyway. E3

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsCycle World Editorial

October 1984 By Paul Dean -

Cycle World Letters

Cycle World LettersCycle World Letters

October 1984 -

Departments

DepartmentsCycle World Roundup

October 1984 By David Edwards -

Features

FeaturesHot-Rodding the Xr500r Engine

October 1984 By Ron Griewe -

Departments

DepartmentsCycle World Things To Do

October 1984 -

Departments

DepartmentsCycle World Race Watch

October 1984 By Ken Vreeke