HOT-RODDING THE XR500R ENGINE

Trying to milk more power from the XR500R engine can be a frustrating process. And time-consuming. And expensive. A couple of simple modifications, like bolting on a megaphone exhaust and rejetting the carbs, can result in a noticeable increase in power; but going beyond that—experimenting with cams, head work, compression ratios and different carburetors—can be a real headache. And until you learn the particular quirks of this engine, you could spend months trying to work out the right combination.

So says C.H. Wheat, owner of International Motorsports in Riverside, California, and a tuner known for his expertise in building fast and reliable four-stroke Singles. Wheat is the man who builds the engines for Team Honda off-road riders Bruce Ogilvie, Chuck Miller and Bob Rutten. That’s why I went to him for advice on hopping up my XR; I figured any engine that produces enough power to satisfy Team Honda’s best, and that stays together for gruelling, long-distance races like the Baja 1000, should be the hot ticket for my needs—trail riding in Baja, playriding in the Mojave, and an occasional desert race or enduro.

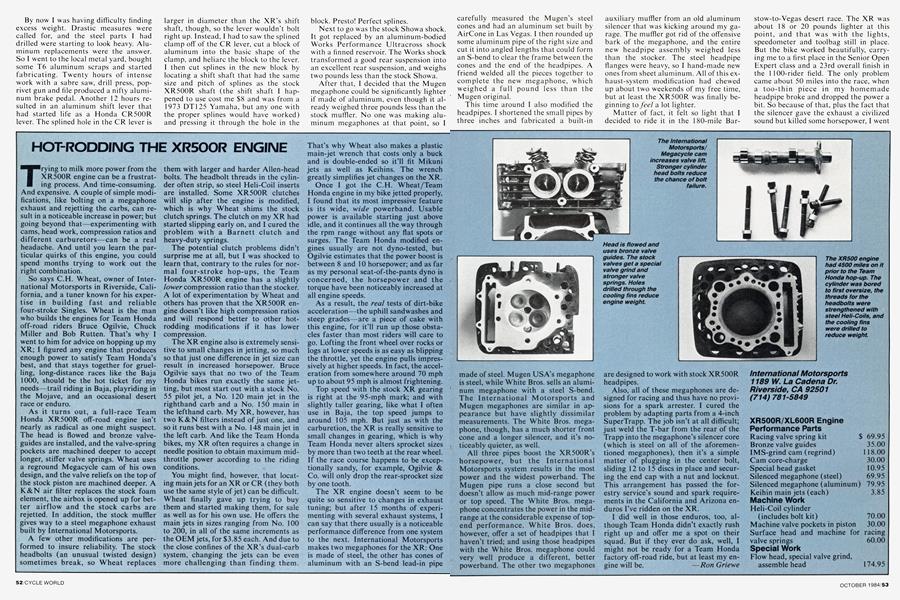

As it turns out, a full-race Team Honda XR500R off-road engine isn’t nearly as radical as one might suspect. The head is flowed and bronze valveguides are installed, and the valve-spring pockets are machined deeper to accept longer, stiffer valve springs. Wheat uses a reground Megacycle cam of his own design, and the valve reliefs on the top of the stock piston are machined deeper. A K&N air filter replaces the stock foam element, the airbox is opened up for better airflow and the stock carbs are rejetted. In addition, the stock muffler gives way to a steel megaphone exhaust built by International Motorsports.

A few other modifications are performed to insure reliability. The stock headbolts (an unusual twisted design) sometimes break, so Wheat replaces them with larger and harder Allen-head bolts. The headbolt threads in the cylinder often strip, so steel Heli-Coil inserts are installed. Some XR500R clutches will slip after the engine is modified, which is why Wheat shims the stock clutch springs. The clutch on my XR had started slipping early on, and I cured the problem with a Barnett clutch and heavy-duty springs.

The potential clutch problems didn’t surprise me at all, but I was shocked to learn that, contrary to the rules for normal four-stroke hop-ups, the Team Honda XR500R engine has a slightly lower compression ratio than the stocker. A lot of experimentation by Wheat and others has proven that the XR500R engine doesn’t like high compression ratios and will respond better to other hotrodding modifications if it has lower compression.

The XR engine also is extremely sensitive to small changes in jetting, so much so that just one difference in jet size can result in increased horsepower. Bruce Ogilvie says that no two of the Team Honda bikes run exactly the same jetting, but most start out with a stock No. 55 pilot jet, a No. 120 main jet in the righthand carb and a No. 150 main in the lefthand carb. My XR, however, has two K&N filters instead of just one, and so it runs best with a No. 148 main jet in the left carb. And like the Team Honda bikes, my XR often requires a change in needle position to obtain maximum midthrottle power according to the riding conditions.

You might find, however, that locating main jets for an XR or CR (they both use the same style of jet) can be difficult. Wheat finally gave up trying to buy them and started making them, for sale as well as for his own use. He offers the main jets in sizes ranging from No. 100 to 200, in all of the same increments as the OEM jets, for $3.85 each. And due to the close confines of the XR’s dual-carb system, changing the jets can be even more challenging than finding them. That’s why Wheat also makes a plastic main-jet wrench that costs only a buck and is double-ended so it’ll fit Mikuni jets as well as Keihins. The wrench greatly simplifies jet changes on the XR.

Once I got the C.H. Wheat/Team Honda engine in my bike jetted properly, I found that its most impressive feature is its wide, wide powerband. Usable power is available starting just above idle, and it continues all the way through the rpm range without any flat spots or surges. The Team Honda modified engines usually are not dyno-tested, but Ogilvie estimates that the power boost is between 8 and 10 horsepower; and as far as my personal seat-of-the-pants dyno is concerned, the horsepower and the torque have been noticeably increased at all engine speeds.

As a result, the real tests of dirt-bike acceleration—the uphill sandwashes and steep grades—are a piece of cake with this engine, for it’ll run up those obstacles faster than most riders will care to go. Lofting the front wheel over rocks or logs at lower speeds is as easy as blipping the throttle, yet the engine pulls impressively at higher speeds. In fact, the acceleration from somewhere around 70 mph up to about 95 mph is almost frightening.

Top speed with the stock XR gearing is right at the 95-mph mark; and with slightly taller gearing, like what I often use in Baja, the top speed jumps to around 105 mph. But just as with the carburetion, the XR is really sensitive to small changes in gearing, which is why Team Honda never alters sprocket sizes by more than two teeth at the rear wheel. If the race course happens to be exceptionally sandy, for example, Ogilvie & Co. will only drop the rear-sprocket size by one tooth.

The XR engine doesn’t seem to be quite so sensitive to changes in exhaust tuning; but after 15 months of experimenting with several exhaust systems, I can say that there usually is a noticeable performance difference from one system to the next. International Motorsports makes two megaphones for the XR: One is made of steel, the other has cones of aluminum with an S-bend lead-in pipe made of steel. Mugen USA’s megaphone is steel, while White Bros, sells an aluminum megaphone with a steel S-bend. The International Motorsports and Mugen megaphones are similar in appearance but have slightly dissimilar measurements. The White Bros, megaphone, though, has a much shorter front cone and a longer silencer, and it’s noticeably quieter, as well.

All three pipes boost the XR500R’s horsepower, but the International Motorsports system results in the most power and the widest powerband. The Mugen pipe runs a close second but doesn’t allow as much mid-range power or top speed. The White Bros, megaphone concentrates the power in the midrange at the considerable expense of topend performance. White Bros, does, however, offer a set of headpipes that I haven’t tried; and using those headpipes with the White Bros, megaphone could very well produce a different, better powerband. The other two megaphones are designed to work with stock XR500R headpipes.

Also, all of these megaphones are designed for racing and thus have no provisions for a spark arrester. I cured the problem by adapting parts from a 4-inch SuperTrapp. The job isn’t at all difficult; just weld the T-bar from the rear of the Trapp into the megaphone’s silencer core (which is steel on all of the aforementioned megaphones), then it’s a simple matter of plugging in the center bolt, sliding 12 to 15 discs in place and securing the end cap with a nut and locknut. This arrangement has passed the forestry service’s sound and spark requirements in the California and Arizona enduros I’ve ridden on the XR.

I did well in those enduros, too, although Team Honda didn’t exactly rush right up and offer me a spot on their squad. But if they ever do ask, well, I might not be ready for a Team Honda factory off-road ride, but at least my engine will be.

Ron Griewe

international Motorsports 1189 W. La Cadena Dr. Riverside, CA 92501 (714) 781-5849

Weight Saved

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsCycle World Editorial

October 1984 By Paul Dean -

Cycle World Letters

Cycle World LettersCycle World Letters

October 1984 -

Departments

DepartmentsCycle World Roundup

October 1984 By David Edwards -

Technical

TechnicalHow Motorcycles W·o·r·k 5

October 1984 By Steve Anderson -

Departments

DepartmentsCycle World Things To Do

October 1984 -

Departments

DepartmentsCycle World Race Watch

October 1984 By Ken Vreeke