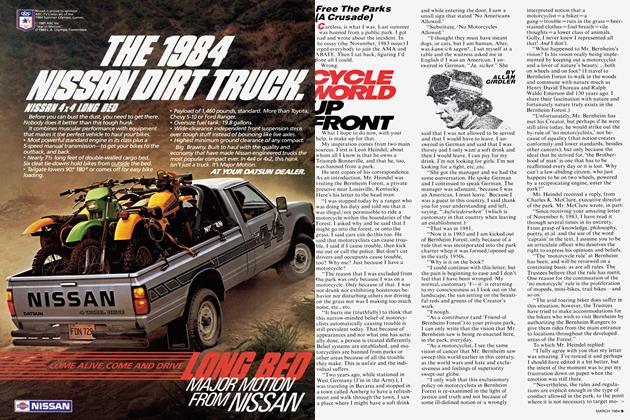

CYCLE WORLD FOLLOW UP

After motorcycles and products are tested, they don’t just disappear. Some bikes are kept around for up to a year, while they pile up thousands of miles. These you get to read about as long-term reports. More often, a bike stays around for another month or two. We

put two or three thousand miles on the odometer, try out a few accessories, and then it goes back. During this time, we sometimes learn things about the motorcycles and accessories, things worth reporting.

Follow Up will be an irregular feature in Cycle World, reporting on things that went wrong, things that went right, and, occasionally, ways to make things right.

Honda VF750F Interceptors

Several problems have surfaced in Honda VF750F Interceptors ridden both on the street and on the racetrack, and Honda has issued warranty fixes for some of the troubles. Most common are problems with camshaft lobes and rocker arms losing their hardfacing and camshaft journals seizing in the cylinder head. Interceptors entered in production class races routinely overheat because anti-freeze is not allowed in racebikes. The slippery ethylene glycol would be unsafe if spilled.

The Interceptor cooling system operates at a high enough temperature that straight water boils off. Some riders have solved the overheating problem by installing a second lower radiator.

Bikes run on the street and track have broken shift pawl springs, causing the transmission to lock in one gear.

Warranty fixes exist for the camshaft hardfacing and seizure problems (a larger oil feed line) and the shift pawl

spring (a stronger spring.) Unfortunately, warranties don’t apply to Interceptors used on the racetrack.

Suzuki GR650 shock preload

5>uzuki’s remote hydraulic spring preload is a clever idea. It enables a rider to easily adjust spring preload on a single rear shock, even when that shock is buried deep inside a motorcycle. On

a long-term GR650, however, when the bike went into the shop for a routine tune-up, the service people found the spring adjusted to minimum preload, even though the adjusting knob was screwed into its housing most of the way. No adjustment was possible. The hydraulic system has apparently leaked. There is no shop repair possible and the service manual specifies that the shock should be sent to Suzuki headquarters for repair, at a cost of $250.

Surely there should be some provision for changing the hydraulic fluid and the seals in this system.

Honda XR500R power tips

F ree horsepower isn’t often possible. This is the exception. The 1983 and ’84 Honda XR500Rs are delivered with extremely lean carburetor jetting. Making the jetting richer gives an immediate increase in midrange power. The price of two main jets and a half hour of your time is all it costs.

Getting to the carbs isn’t an easy job on the XRs but it’s made easier by first removing the seat and gas tank. Complete carburetor removal isn’t necessary, just remove the two Phillips screws that hold the cap on the top of each carb, then remove the screw that locks the slide rocker to the control shaft on each. Next pull the slide up as far as possible and carefully pry the plastic connector link off the rocker. The slide can now be removed and

placed on the work bench. Be careful you don’t mix the slides. We usually do one carb at a time to avoid errors. Remove the two small screws in the bottom of the slide and lift the needle retainer out, then turn the slide upside down and let the needle fall from the slide. Each needle (one per carburetor) has 5 small grooves at the top. These are the height adjustments that control richnessleaness. The clip is set in the 4th groove from the top on the left (primary) carburetor. Use a pair of pliers and carefully pull the clip from the needle and replace it in the 5th (bottom) groove. Moving the clip down raises the needle and makes it richer. Use the same precedure for the right (secondary) carb. The standard needle position on the secondary carb is the 2nd groove (always start the count from the top needle groove), move it to the 3rd groove.

The main jets are also too small and need replacement; remove the cap on the bottom of each float bowl (a 17mm wrench), screw the main jet out using an 8mm wrench (the needle jet may unscrew with the main jet on Keihin carbs but don’t worry about it, just separate the two on the work bench and replace as a unit). The standard main jet in the left (primary carb) is a 1 35, the right carb comes with a 108. Replace the 135 with a 140, the 108 is replaced with a 112 or 115, whichever is easied to obtain. These jetting specs work fine with the stock exhaust and air cleaner.

GS1100ES sidecovers

Shortly after our test of the GSI 100ES was complete, an odd problem cropped up. The pegs holding on the right sidecover broke off when the sidecover was removed.

We've tried unsuccessfully to glue the prongs back on, and have resorted to duct tape to hold the cover on.

The bike now has about 3300 mi. on the odometer and nothing else has given a hint of trouble. It still runs just as

well as it did the day it was delivered and is a favorite foi long trips and local commuting. The power hasn’t gone away, but the rear tire is bald and the chain rollers are loose. The chain is also near the end of its adjustment range, a remarkably short life.

Shoei ER-7 helmet shield

One of the favorite helmets around the CWoffice has become the Shoei ER-7 and the later model Z-100. On the ER-7, though, we’ve had a problem with the faceshield loosening. Lifting and lowering the faceshield gradually loosens the screws that hold the shield in position. This has caused the screws to fall out of two of these helmets. As long as a rider tightens the screws once a week, there appears to be no problem. One rider experimented with Loctite. Screw tightening has been reduced to a once-amonth chore. With the faceshield tightened, the helmets have remained some of our favorites.

Tour Lion Riding Suit

A Tour Lion two-piece insulated nylon riding suit with Early Warning reflective treatment didn’t make it through an entire season without several problems.

The inseam on both legs split open about five inches at the ankle. And the jacket zipper, which has plastic teeth, lost its slider when several teeth came loose. The torn seams created no real hardship other than looking tacky. The broken zipper made it impossible to seal out wind despite the Velcro-equipped wind flap fitted behind the zipper,

View Full Issue

View Full Issue

More From This Issue

-

Departments

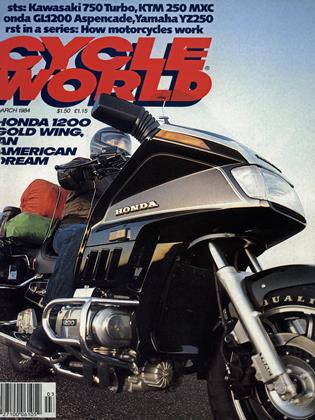

DepartmentsCycle World Up Front

March 1984 By Allan Girdler -

Cycle World Letters

Cycle World LettersCycle World Letters

March 1984 -

Departments

DepartmentsCycle World Round Up

March 1984 -

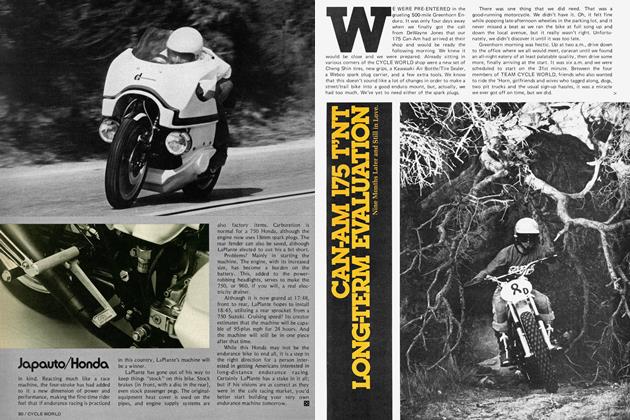

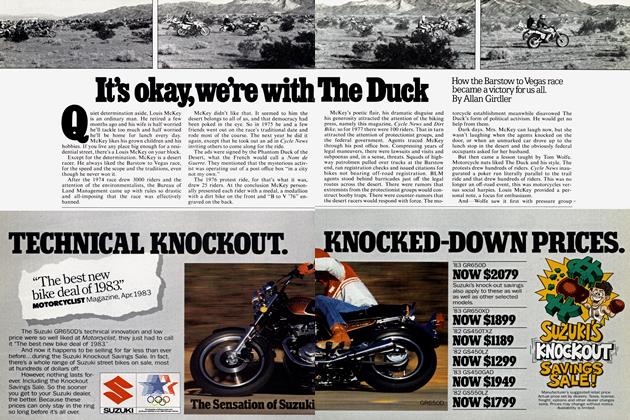

Competition

CompetitionIt's Okay, We're With the Duck

March 1984 By Allan Girdler -

Special Feature

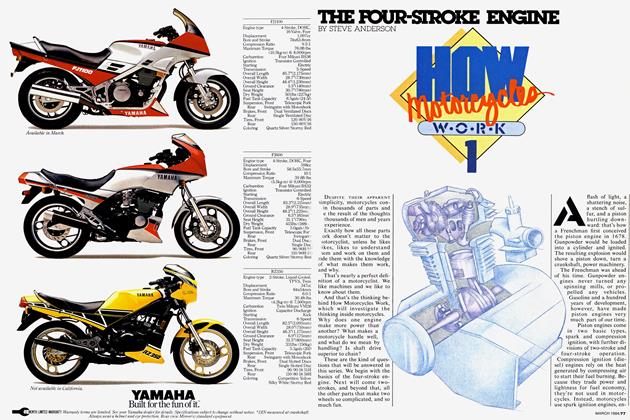

Special FeatureHow Motorcycle W.O.R.K 1

March 1984 By Steve Anderson -

Technical

TechnicalPainting Plastic

March 1984