More Power For Honda’s XR500

Honda’s Kit And Our Own

Getting more horsepower from a two-stroke is relatively simple: align the ports, bolt on a larger carburetor and install a good expansion pipe. Presto, more power. And it doesn’t take long to do the complete job.

Four-strokes are another problem. Just getting the head off most of them requires engine removal first. After the head and cylinder are removed the first-timer and two-stroke rider are usually baffled by the complexity. The two-stroke has a piston, a cylinder full of ports and a simple head making the horsepower: the four-stroke has a complicated head with valves, valve guides, springs, cams, chains, oil passages and—the parts just keep piling up. Parts go round ’n’ round, up and down, and. . . . who knows.

The Honda XR500 engine is one of the multi-piece four-stroke engines. We have one in a C&J racing frame and decided to try some of the engine hop-up parts available. We tried a couple different approaches. First we bolted on the complete performance kit offered by American Honda, then we collected single pieces from different firms and made our own kit.

Honda’s Kit

Honda’s kit is made from sub-kits and won’t require searching for gaskets, cables or odds and ends. The kit consists of the following sub kits: high performance muffler, high compression piston with rings and gasket set, camshaft, 37mm Keihin carb (stock is 34mm) with manifold, throttle and cable and hoses. All a buyer has to do is bolt the pieces onto the engine. The carburetor is prejetted and the cam installation doesn’t require machine work to the head. Horsepower is claimed to increase from 35.9 at 6500 rpm to 40.8 at 6000. All figures are crankshaft power so rear wheel bhp is a little less.

Honda’s sub kits bolt right on to stock XRs with a minimum of mechanical knowledge required. We used a Honda shop manual and installed all of the pieces with no problems. We put all of the sub kits on at once but it doesn’t have to be done that way as the carb, pipe, etc, are available separately. The kit silencer is ugly and didn’t do much for the looks of the trick C&J but we vowed to try it anyway. The Honda parts increased power in the mid-range and at low engine speeds. The Honda cam is a torquer and designed for woods type riding. The high compression piston made it harder to kick and with poor quality fuel the bike pinged. Although the Honda kits are well designed and installation is relatively simple, the cam grind didn’t fit our riding areas. More torque isn’t needed on an XR500 engine for desert terrain.

Our Engine

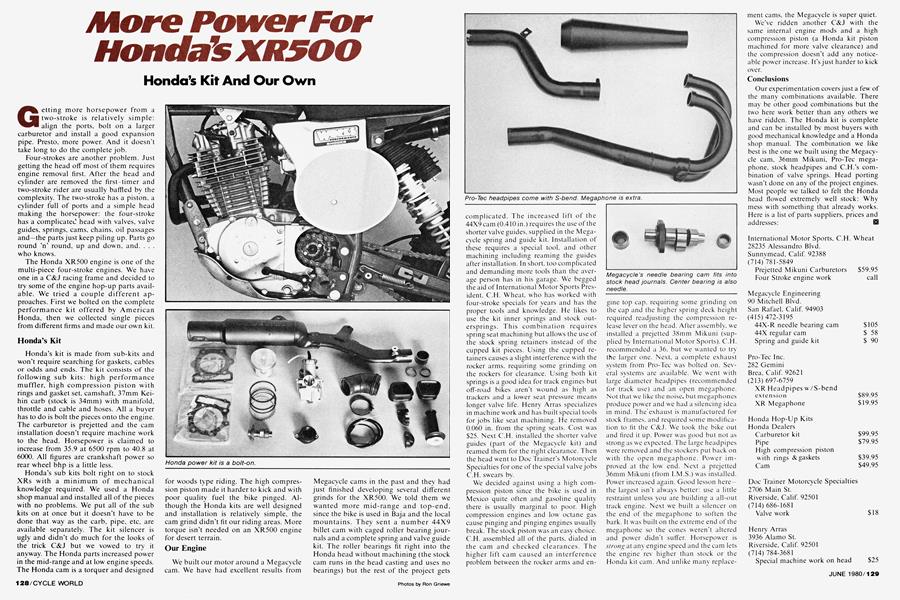

We built our motor around a Megacycle cam. We have had excellent results from Megacycle cams in the past and they had just finished developing several different grinds for the XR500. We told them we wanted more mid-range and top-end, since the bike is used in Baja and the local mountains. They sent a number 44X9 billet cam with caged roller bearing journals and a complete spring and valve guide kit. The roller bearings fit right into the Honda head without machining (the stock cam runs in the head casting and uses no bearings) but the rest of the project gets complicated. The increased lift of the 44X9 cam (0.410 in.) requires the use of the shorter valve guides, supplied in the Megacycle spring and guide kit. Installation oí these requires a special tool, and other machining including reaming the guides after installation. In short, too complicated and demanding more tools than the average person has in his garage. We begged the aid of International Motor Sports President, C.H. Wheat, who has worked with four-stroke specials for years and has the proper tools and knowledge. He likes to use the kit inner springs and stock outersprings. This combination requires spring seat machining but allows the use of the stock spring retainers instead of the cupped kit pieces. Using the cupped retainers causes a slight interference with the rocker arms, requiring some grinding on the rockers for clearance. Using both kit springs is a good idea for track engines but oif-road bikes aren’t wound as high as trackers and a lower seat pressure means longer valve life. Henry Arras specializes in machine work and has built special tools for jobs like seat machining. He removed 0.060 in. from the spring seats. Cost was $25. Next C.H. installed the shorter valve guides (part of the Megacycle kit) and reamed them for the right clearance. Then the head went to Doc Trainer's Motorcycle Specialties for one of the special valve jobs C.H. swears by.

We decided against using a high compression piston since the bike is used in Mexico quite often and gasoline quality there is usually marginal to poor. High compression engines and low octane gas cause pinging and pinging engines usually break. The stock piston w'as an easy choice. C.H. assembled all of the parts, dialed in the cam and checked clearances. The higher lift cam caused an interference problem between the rocker arms and engine top cap, requiring some grinding on the cap and the higher spring deck height required readjusting the compression release lever on the head. After assembly, we installed a prejetted 38mm Mikuni (supplied by International Motor Sports). C.H. recommended a 36. but we wanted to try the larger one. Next, a complete exhaust system from Pro-Tec was bolted on. Several systems are available. We went with large diameter headpipes (recommended for track use) and an open megaphone. Not that we like the noise, but megaphones produce power and we had a silencing idea in mind. The exhaust is manufactured for stock frames, and required some modification to fit the C&J. We took the bike out and fired it up. Power was good but not as strong as we expected. The large headpipes were removed and the Stockers put back on with the open megaphone. Power improved at the low end. Next a prejetted 36mm Mikuni (from I.M.S.) was installed. Power increased again. Good lesson here— the largest isn’t always better: use a little restraint unless you are building a all-out track engine. Next we built a silencer on the end of the megaphone to soften the bark. It was built on the extreme end of the megaphone so the cones weren't altered and power didn’t suffer. Horsepower is strong at any engine speed and the cam lets the engine rev higher than stock or the Honda kit cam. And unlike many replacement cams, the Megacycle is super quiet.

We’ve ridden another C&J with the same internal engine mods and a high compression piston (a Honda kit piston machined for more valve clearance) and the compression doesn’t add any noticeable power increase. It’s just harder to kick over.

Conclusions

Our experimentation covers just a few of the many combinations available. There may be other good combinations but the two here work better than any others we have ridden. The Honda kit is complete and can be installed by most buyers with good mechanical knowledge and a Honda shop manual. The combination we like best is the one we built using the Megacycle cam, 36mm Mikuni, Pro-Tec megaphone. stock headpipes and C.H.’s combination of valve springs. Head porting wasn’t done on any of the project engines. Most people we talked to felt the Honda head flowed extremely well stock: Why mess with something that already works. Here is a list of parts suppliers, prices and addresses: