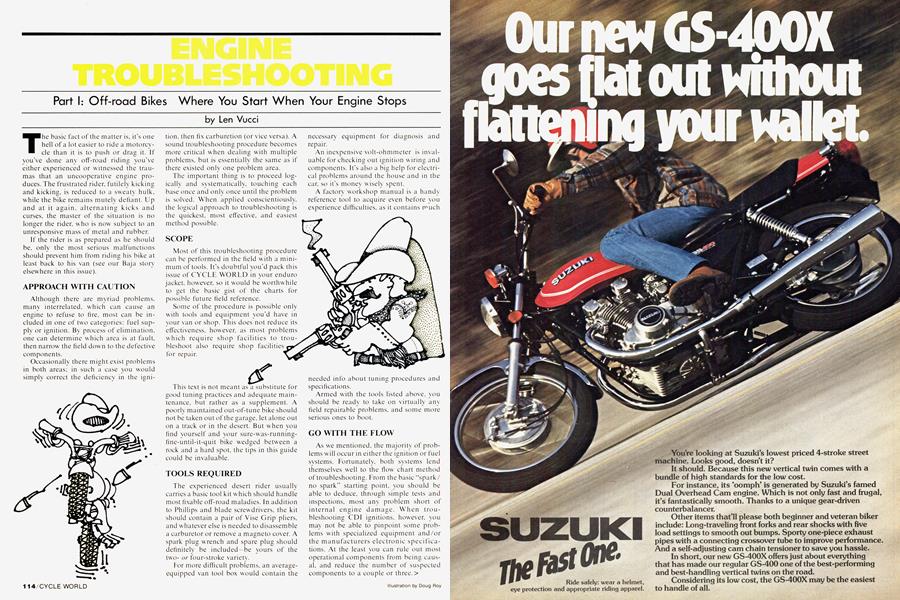

ENGINE TROUBLESHOOTING

Part l: Off-road Bikes Where You Start When Your Engine Stops

Len Vucci

The basic fact of the matter is. it's one hell of a lot easier to ride a motorcy-

cle than it is to push or drag it. If you’ve done any off-road riding you’ve either experienced or witnessed the traumas that an uncooperative engine produces. The frustrated rider, futilely kicking and kicking, is reduced to a sweaty hulk, while the bike remains mutely defiant. Up and at it again, alternating kicks and curses, the master of the situation is no longer the rider, who is now subject to an unresponsive mass of metal and rubber.

If the rider is as prepared as he should be, only the most serious malfunctions should prevent him from riding his bike at least back to his van (see our Baja story elsewhere in this issue).

APPROACH WITH CAUTION

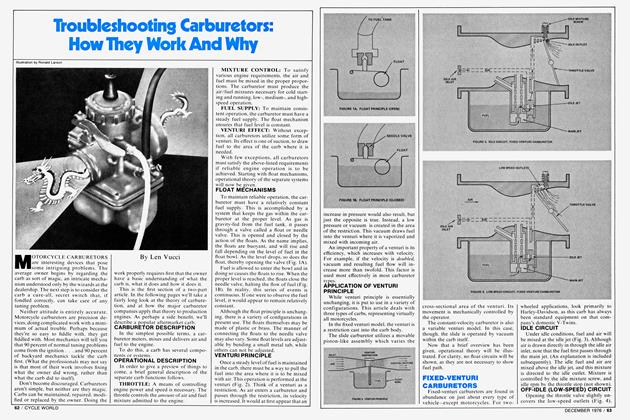

Although there are myriad problems, many interrelated, which can cause an engine to refuse to fire, most can be included in one of two categories: fuel supply or ignition. By process of elimination, one can determine which area is at fault, then narrow the field down to the defective components.

Occasionally there might exist problems in both areas; in such a case you would simply correct the deficiency in the ignition. then fix carburetion (or vice versa). A sound troubleshooting procedure becomes more critical when dealing with multiple problems, but is essentially the same as if there existed only one problem area.

The important thing is to proceed logically and systematically, touching each base once and only once until the problem is solved. When applied conscientiously, the logical approach to troubleshooting is the quickest, most effective, and easiest method possible.

SCOPE

Most of this troubleshooting procedure can be performed in the field with a minimum of tools. It’s doubtful you'd pack this issue of CYCLE WORLD in your enduro jacket, however, so it would be worthwhile to get the basic gist of the charts for possible future field reference.

Some of the procedure is possible only with tools and equipment you'd have in your van or shop. This does not reduce its effectiveness, however, as most problems which require shop facilities to troubleshoot also require shop facilities for repair.

This text is not meant as a substitute for good tuning practices and adequate maintenance. but rather as a supplement. A poorly maintained out-of-tune bike should not be taken out of the garage, let alone out on a track or in the desert. But when you find yourself and your sure-was-runningfine-until-it-quit bike wedged between a rock and a hard spot, the tips in this guide could be invaluable.

TOOLS REQUIRED

The experienced desert rider usually carries a basic tool kit which should handle most fixable off-road maladies. In addition to Phillips and blade screwdrivers, the kit should contain a pair of Vise Grip pliers, and whatever else is needed to disassemble a carburetor or remove a magneto cover. A spark plug wrench and spare plug should definitely be included—be yours of the twoor four-stroke variety.

Lor more difficult problems, an averageequipped van tool box would contain the necessary equipment for diagnosis and repair.

An inexpensive volt-ohmmeter is invaluable for checking out ignition wiring and components. It’s also a big help for electrical problems around the house and in the car. so it's money wisely spent.

A factory workshop manual is a handy reference tool to acquire even before you experience difficulties, as it contains much

needed info about tuning procedures and specifications.

Armed with the tools listed above, you should be ready to take on virtually any field repairable problems, and some more serious ones to boot.

GO WITH THE FLOW

As we mentioned, the majority of problems will occur in either the ignition or fuel systems. Fortunately, both systems lend themselves well to the flow chart method of troubleshooting. From the basic “spark/ no spark" starting point, you should be able to deduce, through simple tests and inspections, most any problem short of internal engine damage. When troubleshooting CDI ignitions, however, you may not be able to pinpoint some problems with specialized equipment and/or the manufacturers electronic specifications. At the least you can rule out most operational components from being.causal, and reduce the number of suspected components to a couple or three.>

article

CARBURETION TROUBLESHOOTING CHART

CON

IGNITION TROUBLESHOOTING CHART

View Full Issue

View Full Issue