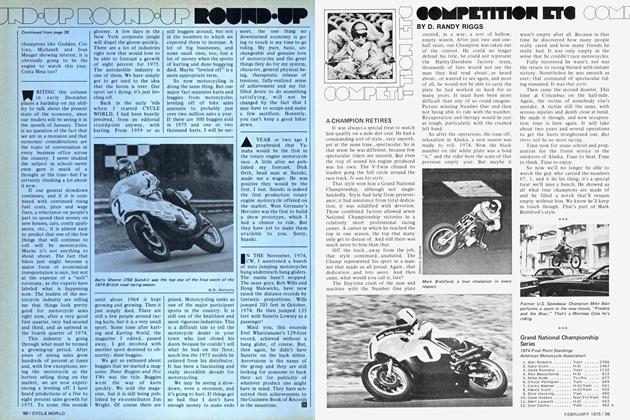

K-R TT500 Yamaha

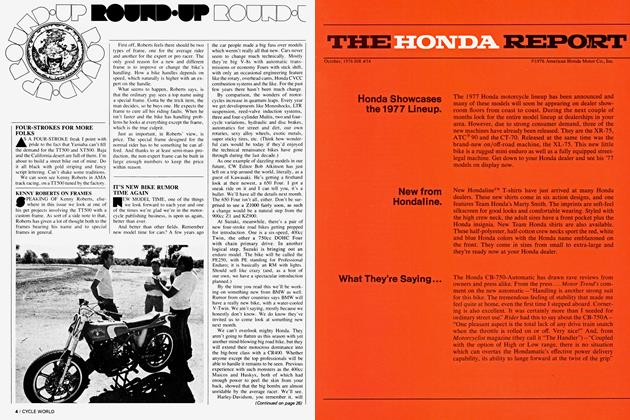

Combining Yamaha’s Versatile Thumper With A Chassis Designed And Built By Kenny Roberts Creates A Very Serious Playbike

D. Randy Riggs

EVER WONDER what kind of bike a champion like Kenny Roberts would design if there were no factory engineers to censor his ideas and thoughts? Well, you don't have to wonder any longer because Kenny has recently formed his own company, K-R Racing Specialties and has begun to manufacture motorcycle and bicycle motocross frames.

I was able to obtain one of these specially manufactured bikes from Sparky Edmonston, West Coast representative for Lectron Carburetors. Testing the machine on Kenny’s practice track, I was really impressed with the bike’s agility and handling prowess.

Kenny’s reasons for entering the frame manufacturing business were relatively straightforward. He felt that the existing> frame builders had progressed little over the last couple of years and were reluctant to try new ideas. He had a few of his own that he felt would eliminate the handling problems he had experienced, but people either wouldn’t listen, or were too busy turning out existing designs to take time out and experiment. The only way he could get what he wanted was to build it himself, and that's precisely what he did.

K-R 500

Yamaha

For some, it may come as a surprise to learn that the K-R frame is manufactured from mild steel, not chrome-moly, as is the fashion with most accessory units. Naturally, this effects quite a savings in cost, partially in material, but mainly in labor expense since it requires more time to heli-arc chrome-moly than it does to wire weld mild steel. Roberts claims that the use of chrome-moly isn’t as necessary for strength as some people think, that the design of the chassis is of foremost importance when it comes to rigidity. As an example he points out that his ultra special factory OW31 Yamaha road racer has a frame built from mild steel.

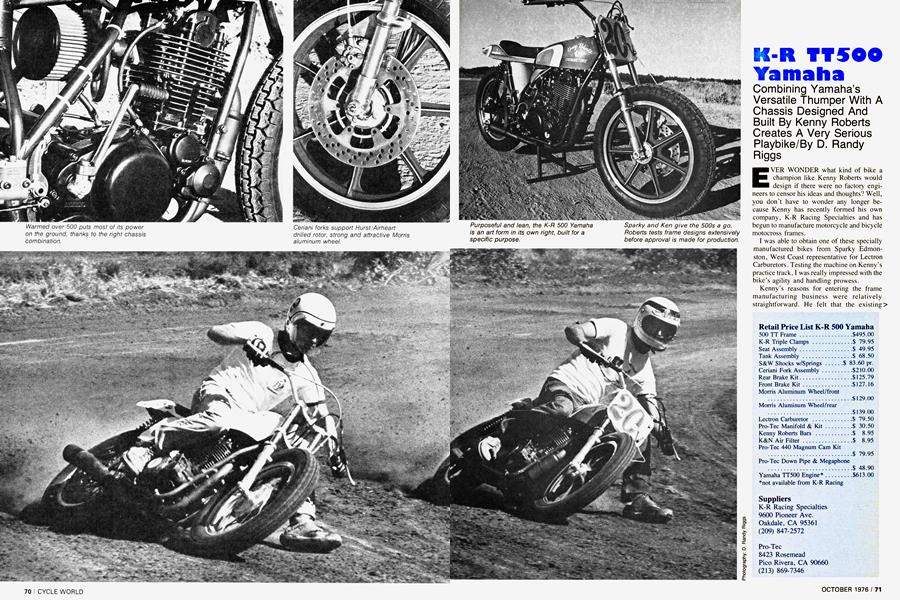

The K-R Frame Kit includes all the necessary hardware and assorted bits to bolt things together. Grade 8 bolts are used throughout and the rear axle and related parts are included as well. On a machine like this one, individual components such as suspension, handlebars, control cables, etc., are usually preference items selected by the rider. Edmonston, the owner of the bike pictured here, opted for Ceriani Forks and S&W rear shocks, but Betor front suspension units are available to fit K-R triple clamps, and the choice of dampers at the rear is almost limitless.

Edmonston claims that he’s never had a custom-framed machine go together so easily. He built the bike in three nights of work after getting all the necessary pieces together. Besides a normal assortment of open-end metric wrenches and sockets, the only “special’’ tool required was a %-in. drill. The engine slipped into the frame without a crowbar; only the strength of extra helpers was needed. Nothing seemed misaligned or out of place, owing to the high degree of workmanship.

Sparky used K-R aluminum triple clamps designed for Ceriani road race forks. The clamps come with all the necessary bearings and securing bolts for attachment to the motorcycle. The front end is a bolt-on operation, but you do need to experiment with different weights of fork oil and springs. Sparky used 20-wt. Bel-Ray fork oil coupled with “light" Ceriani springs. Since the machine is designed to run on smoother surfaces than would normally be expected for a cross-country bike, fork travel is not excessive at about 5 inches. Complementing this amount of travel are stiffer springs than normally used on a motocross suspension unit.

(Continued on page 92)

$2300

Continued from page 73

S&W is a very reputable name in rear suspension and one doesn't have to look far in the pit area of a race meet to gaze upon one of its components. Rather than experiment, Edmonston stuck with the racer's choice. Fitted to the 500 are 14.5-in. S&W Freon Bag units with 80-lb. non-progressive springs. The box section swinging arm has four low'er shock mounting positions and one upper, allowing for subtle but effective changes in the rear suspension to suit riding conditions and rider preference.

Wire spoked wheels and hubs would have been slightly less expensive to purchase, but Sparky liked the beauty and strength of the Morris aluminum wheel, and opted for one at each end of the machine. There is no doubt that the wheels add a tremendous amount of posh to an already classy motorcycle. The wheels come complete with the proper bearings and spacers. All one need do is hook up the hydraulic Hurst-Airheart disc brakes at both ends to complete the wheel system. Tires were arranged through Bill Robinson of Goodyear, a 3.50-19 DT up front, and a 4.00-18 DT at the rear. These will work well on a variety of tracks and on smooth fireroads where an abundance of throttle and sliding is the order of the day.

Yamaha's 500 Single doesn't need much fiddling for extra power. Sparky warmed his over with a 36mm Lectron carb mated to a Pro-Tec installation kit and cable (CW, July '76). Pro-Tec also has a good selection of camshaft kits from which he picked the 440 Magnum. He went yet another step with their down pipe, which he modified slightly with a built-in silencer, to change the engine's power characteristics. K&N filters were used for the carburetor and engine breather tube.

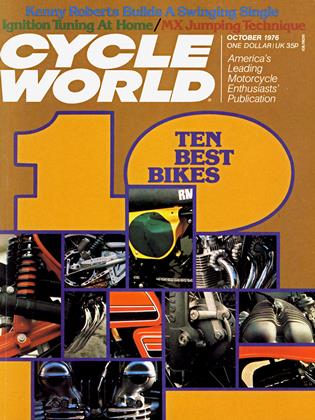

Glasswork is supplied by K-R Specialties and is designed to attach directly to the new chassis with no modifying or hassles. Rick Marquis applied the paint, striping and lettering, which is one of the highlights of the bike. Coupling this to the gun metal gray chassis, black engine unit and Morris wheels makes this K-R 500 Yamaha a hard one to miss and even harder not to appreciate.

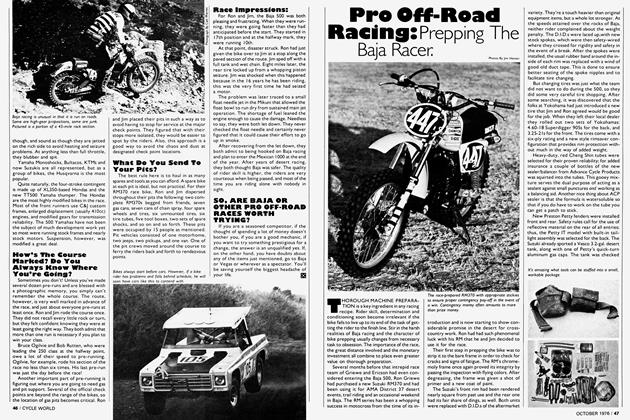

While it may be easy to appreciate, it certainly isn't a machine for the masses. Besides being expensive, whether or not one already owns a 500 Yamaha, the bike has a very limited use potential. You can either race scrambles on it or go fire roading. Any attempt at making a cross-country or rough road excursion would result in misery for the rider. The seat is intended for only brief periods of use, the suspension is taut, travel limited and ground clearance minimal. But that’s the whole point. This is a machine that was built for Edmonston’s specific purpose: an occasional race and a once-in-awhile fling down a forgotten firebreak.

(Continued on page 96)

Continued from page 92

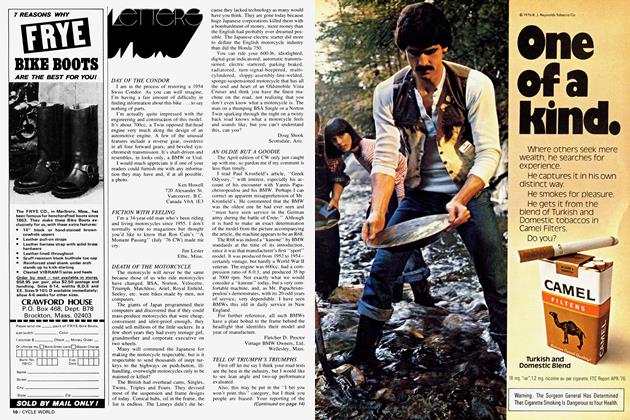

Riding the machine is really an experience, particularly if you're one who appreciates the power output of a large-bore thumper. The bike feels almost toylike when you first climb on, especially if you're at all used to the stock Yamaha TT500. But the engine sounds almost the same, so you really can't forget what's beneath you. Kenny's track is a slightly larger version of the course set up annually in the Astrodome, with a smaller jump, and I had to allow myself to get used to both the track and the motorcycle at the same time.

It feels very strange to ride a smooth track machine after many miles on hordes of motocrossers and enduro type motorcycles. The handlebars are narrower and swept back, the seat is hard, the suspension stiff and everything happens more quickly. Ruts or bumps that a motocrosser would totally ignore are suddenly magnified and are to be avoided if at all possible. Forget any ideas that there may be similarity in handling between a stock TT500 and the K-R-framed version, because there is none.

Stuffing a stock TT500 into a corner usually results in a plowing front wheel or even a front end washout, certainly nothing to instill confidence. Do the same with the K-R chassis and you had better be ready to turn when the bars are pointed to either side because this one turns right now! It felt awkward at first, but with some tips from National Expert Jimmy Odom and Kenny, the bike and I began working as a team. The secret is lots of throttle to get the rear tire spinning. The rider pitches the bike in a sideways movement into the corner, then controls the drift with throttle. Angle is varied with subtle steering movements. I have yet to sample anything that afforded quite the degree of control on a smooth dirt track that the K-R 500 Yamaha did.

Current production frames include those for the 350 Honda, 360 Yamaha, 250 MX and YZ Yamaha and Hodaka 250 in Short Track geometry. The TT frame is available for the 500 Yamaha. Testing is currently being completed for Bultaco frames, and one of Kenny’s key projects is a complete new chassis for 750cc motors, for use on half-mile and mile tracks. When these are completed, two more versions for the 500 Yamaha will be built. One will be for cowtrailing. The other will be a streetable cafe racer. We can hardly wait! n

View Full Issue

View Full Issue