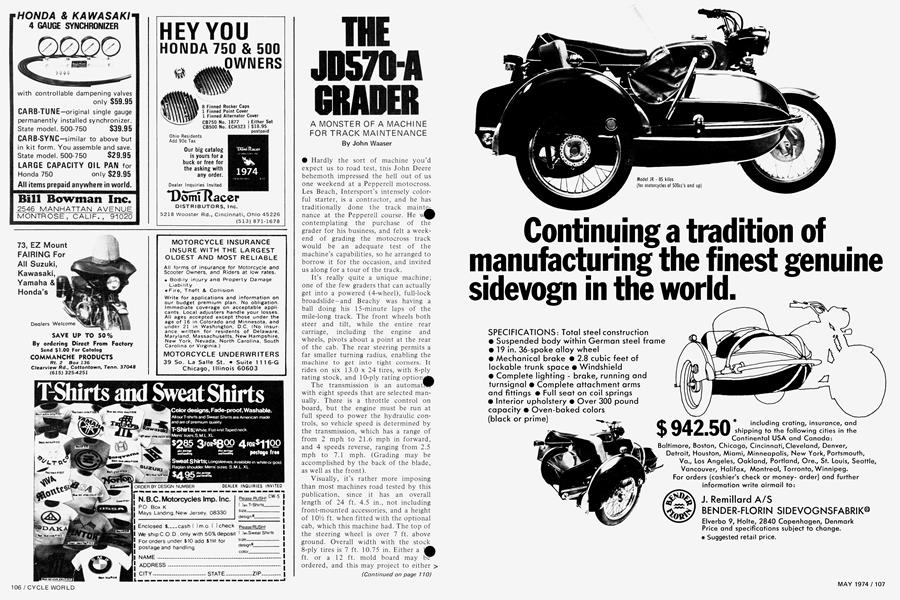

THE JD570-A GRADER

A MONSTER OF A MACHINE FOR TRACK MAINTENANCE

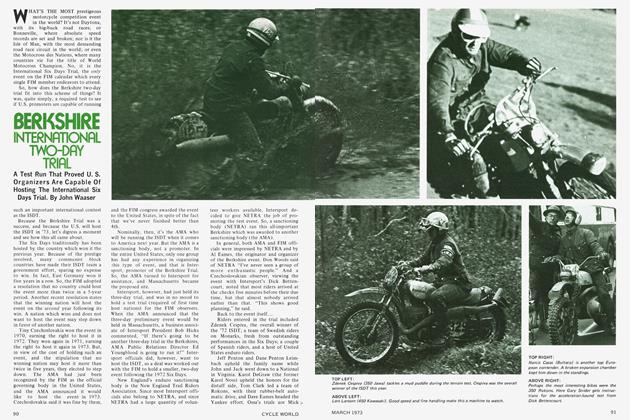

John Waaser

Hardly the sort of machine you’d expect us to road test, this John Deere behemoth impressed the hell out of us one weekend at a Pepperell motocross. Les Beach, Intersport’s intensely colorful starter, is a contractor, and he has traditionally done the track maintenance at the Pepperell course. He w contemplating the purchase of the grader for his business, and felt a weekend of grading the motocross track would be an adequate test of the machine’s capabilities, so he arranged to borrow it for the occasion, and invited us along for a tour of the track.

It’s really quite a unique machine; one of the few graders that can actually get into a powered (4-wheel), full-lock broadslide—and Beachy was having a ball doing his 15-minute laps of the mile-long track. The front wheels both steer and tilt, while the entire rear carriage, including the engine and wheels, pivots about a point at the rear of the cab. The rear steering permits a far smaller turning radius, enabling the machine to get into tight corners. It rides on six 13.0 x 24 tires, with 8-ply rating stock, and 10-ply rating optiomj^

The transmission is an automatw^ with eight speeds that are selected manually. There is a throttle control on board, but the engine must be run at full speed to power the hydraulic controls, so vehicle speed is determined by the transmission, which has a range of from 2 mph to 21.6 mph in forward, and 4 speeds reverse, ranging from 2.5 mph to 7.1 mph. (Grading may be accomplished by the back of the blade, as well as the front).

Visually, it’s rather more imposing than most machines road tested by this publication, since it has an overall length of 24 ft. 4.5 in., not including front-mounted accessories, and a height of IOV2 ft. when fitted with the optional cab, which this machine had. The top of the steering wheel is over 7 ft. above ground. Overall width with the stock 8-ply tires is 7 ft. 10.75 in. Either a ft. or a 12 ft. mold board may b^ ordered, and this may project to either > (Continued on page 110) side by more than 2 ft. Weight of the basic machine is 20,025 lb., but with the front-mounted scarifier and wheel weights (which this machine did not have), the weight climbs to 21,503 lb.

Continued from page 106

The fuel tank holds 50 gallons, good for about a day’s use, which works out to a very low mileage figure. Maybe the EPA should ban them? Crankcase capacity is 12 quarts, which isn’t really that much (hell, that’s a good breakfast for a Jaguar), but the transmission, which includes the hydraulic system for operating the blade and other machine functions, holds a whopping 21 gallons of John Deere-type 303 Special Purpose Oil or the equivalent. Turning radius is 18 ft., not much more than some bikes, and less than most cars.

Hydraulic disc brakes work on four rear tandem wheels only, whiiÄi hand operated parking brake works on drums on the same wheels. The sixcylinder engine puts out 85 net horsepower at 2300 rpm, and electrics are 12 volt, with a 55 amp alternator, and two 6-hour reserve capacity batteries.

Maintenance is somewhat special, also, as, for instance, the rig has no fewer than 44 grease nipples, which must be serviced on a daily basis. Engine oil changes (12 quarts, remember) are recommended about every two weeks. Most of the engine accessories look easy to get into, but a few are not, even on this new rig. After a few weeks heavy use, you’d want to steam clean it before tackling a fan belt or other routine service job.

Driving the grader is no less difficult than maintaining it. There are no fewer than 1 6 hand-and-foot controls, pln(^^ least eight switches, so it would appear to have been designed for siamese-twin octopi (joined at the brain). Coordination is an absolute must. You wouldn’t think fine grading would matter too much on a rough and tumble motocross cross like Pepperell, but Beachy also maintains the TT scrambles course at Middleboro with this rig. Smooth transitions are essential from the straight onto the banked turns.

The operator of this machine should be a burly fellow, with a deft touch on the controls, capable of raising one side of the mold board, while lowering the other side, both gradually and smoothly, while simultaneously steering the rig through a corner. Some of the controls move from side to side, while some go back and forth. One T-handle, which both turns the mold board and controls the side projection, must both rotated and moved from side to side. If only one movement of the blade is desired, the corresponding movement must be made on the control without disturbing the other setting.

(Continued on page 116)

Continued from page 110

Since a rut in the surface at the front wheels will disturb the height of the mold board some six feet behind the rut (or bump), the operator must constantly keep his eyes well ahead to observe track conditions. But he must also know where the tip of the mold board is at all times, and keep the rear end from getting into trouble caused by the articulated steering. All things considered, it takes a lot more talent to maintain a motocross course than to ride one.

Intersport has discovered that the best way to tackle the problem of course maintenance is to grade the track the day AFTER the race, then let it sit through rain and sun until the next race. That way, the dirt that fills into the holes has a chance to settle, and when the riders tackle the course again, it is much more natural, and less likely to go to pieces under the duress of a long and grueling motocross. If large bumps, stones, and ruts come up during a > motocross, they can be leveled easily enough during the intermission. But if maintenance is left until just before a r^e, then the soft dirt piled into the l^^s quickly leaves, and the resulting ruts and bumps that crop up during the event are twice as large, and potentially more dangerous.

The Pepperell course has retained its rider appeal, in spite of its rocky surface and lack of built-up jumps, simply because Intersport has left it in its natural state. One or two areas have been carved up just enough to allow the bikes to leave the ground, but nothing like one other New England course, where the promoters have decided to please the spectators with death-defying jumps.

Built-up jumps are tremendously scary, not only because they are so high, or so long, but also because there is nothing to hold the surface together. Even where calcium and other chemicals are added to the built-up areas, the top ajtface changes a bit every lap, and IRt is the proper line one lap, could kill a rider the next.

Pepperell is as rough and rugged as any course in the country, and the rocks require that protective clothing be worn. But a careful maintenance schedule, lengthy waits between race dates to allow the track to settle, and the decision to allow the track to follow natural contours of the land, have made it a relatively safe place to race.

Following a race date, Beachy explains, scarifying equipment (sort of like a toothed “cowcatcher” available as an optional accessory on the JD 570-A), can be used to reclaim expended and spoiled topsoil. The projection of the mold board allows the soil to be reclaimed from berms and sidelines. After this material is scarified and reclaimed, the whole surface may be leveled with

»grader, and then the track is allowed settle before the next event. Of course, for this to work, the track must be absolutely closed to practice and other use by would-be racers. A professional promoter has an advantage here over a club that promotes races on its property, where club members would insist on practicing.

During the race, it takes several people to run the grader and the water truck, and to perform track maintenance. But Beachy’s employees are always willing to work at Pepperell for minimal salary. Les explains that the races attract crowds of scantily-clad feminine bodies, and his employees find looking at them ample reward! So Pepperell always has a crew of experienced helpers to perform track maintenance.

As an example of the sort of thing that can be done with this kind of J»pment, there used to be one stretch ai Pepperell where the mud was so > heavy that the bikes would create deep ruts whose sides would knock the machines out of gear. Naturally, this area was difficult to reclaim after a race, and quickly got out of shape during the races. Beach came in with his equipment after one race, hauled out all of the mud, threw in a couple of feet of gravel, then tossed the mud back on top. Now the area drains much better; and while it is still muddy, the deep, dangerous ruts are gone. The area holds up pretty well for a two-day event, and can be easily reclaimed before the next race.

(Continued on page 118)

Continued from page 117

The JD 570-A grader is not cheap; it sells for $28,000 as it is set up here. But Beachy puts that into perspective handily. Assuming that a two-day motocross at Pepperell attracts 500 bikes, and assuming that an average cost of new and used machines there might be $800 each, then the track is being torn apart by $400,000 worth of equipment. At that rate, $28,000 to put it back in shape is a bargain. Beautiful it ain’t; but as one of the most unusual machines that we’ve tested, the JD 570-A has to rank as one of the most useful, too. RSI

SPECIFICATIONS

HORSEPOWER (at 2,300 rpm):

SAE net (at 500-ft. altitude and 85 F. temp.) Engine equipped with fan, air cleaner, water pump, lubricating oil pump, fuel pump, alternator, and muffler ... 85

TRANSMISSION

Full Power Shift, 8 forward speeds and 4 reverse. Hydraulic direction reverser. Lock, unlock differential.

TRAVEL SPEEDS (at 2,300 rpm):

BRAKES

Foot operated, hydraulic-actuated wet-disk, effective on 4 tandem wheels. Hand-operated parking brake; mechanical expanding dry shoe; effective on 4 tandem wheels.

OPERATING WEIGHT:

With Standard Equipment

On Front Wheels .... 5,705 lb. (2608 kg) On Rear Wheels .... 14,320 lb. (6495 kg)

Total............ 20,025 lb. (9083 kg)

With Scarifier........ 20,903 lb. (9481 kg)

With Scarifier and

Wheel Weights..... 21,503 lb. (9753 kg)