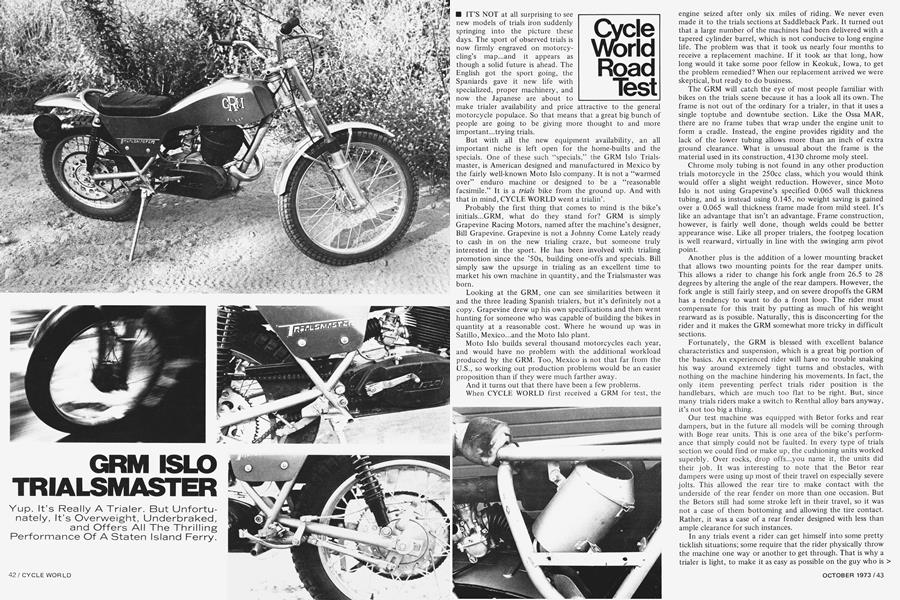

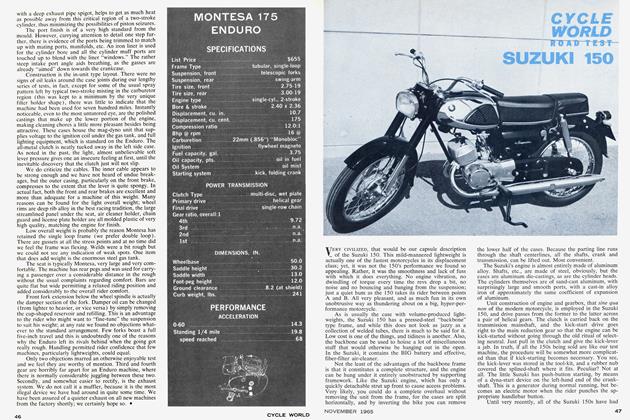

GRM ISLO TRIALSMASTER

Yup. It’s Really A Trialer. But Unfortunately, It’s Overweight, Underbraked, and Offers All The Thrilling Performance Of A Staten Island Ferry.

Cycle World Road Test

IT’S NOT at all surprising to see new models of trials iron suddenly springing into the picture these days. The sport of observed trials is now firmly engraved on motorcycling’s map...and it appears as though a solid future is ahead. The English got the sport going, the Spaniards gave it new life with specialized, proper machinery, and now the Japanese are about to

make trialer availability and price attractive to the general motorcycle populace. So that means that a great big bunch of people are going to be giving more thought to and more important...trying trials.

But with all the new equipment availability, an all important niche is left open for the home-builts and the specials. One of these such “specials,” the GRM Islo Trialsmaster, is American designed and manufactured in Mexico by the fairly well-known Moto Islo company. It is not a “warmed over” enduro machine or designed to be a “reasonable facsimile.” It is a trials bike from the ground up. And with that in mind, CYCLE WORLD went a trialin’.

Probably the first thing that comes to mind is the bike’s initials...GRM, what do they stand for? GRM is simply Grapevine Racing Motors, named after the machine’s designer, Bill Grapevine. Grapevine is not a Johnny Come Lately ready to cash in on the new trialing craze, but someone truly interested in the sport. He has been involved with trialing promotion since the ’50s, building one-offs and specials. Bill simply saw the upsurge in trialing as an excellent time to market his own machine in quantity, and the Trialsmaster was born.

Looking at the GRM, one can see similarities between it and the three leading Spanish trialers, but it’s definitely not a copy. Grapevine drew up his own specifications and then went hunting for someone who was capable of building the bikes in quantity at a reasonable cost. Where he wound up was in Satillo, Mexico...and the Moto Islo plant.

Moto Islo builds several thousand motorcycles each year, and would have no problem with the additional workload produced by the GRM. Too, Mexico is not that far from the U.S., so working out production problems would be an easier proposition than if they were much farther away.

And it turns out that there have been a few problems.

When CYCLE WORLD first received a GRM for test, the engine seized after only six miles of riding. We never even made it to the trials sections at Saddleback Park. It turned out that a large number of the machines had been delivered with a tapered cylinder barrel, which is not conducive to long engine life. The problem was that it took us nearly four months to receive a replacement machine. If it took us that long, how long would it take some poor fellow in Keokuk, Iowa, to get the problem remedied? When our replacement arrived we were skeptical, but ready to do business.

The GRM will catch the eye of most people familiar with bikes on the trials scene because it has a look all its own. The frame is not out of the ordinary for a trialer, in that it uses a single toptube and downtube section. Like the Ossa MAR, there are no frame tubes that wrap under the engine unit to form a cradle. Instead, the engine provides rigidity and the lack of the lower tubing allows more than an inch of extra ground clearance. What is unusual about the frame is the material used in its construction, 4130 chrome moly steel.

Chrome moly tubing is not found in any other production trials motorcycle in the 250cc class, which you would think would offer a slight weight reduction. However, since Moto Islo is not using Grapevine’s specified 0.065 wall thickness tubing, and is instead using 0.145, no weight saving is gained over a 0.065 wall thickness frame made from mild steel. It’s like an advantage that isn’t an advantage. Lrame construction, however, is fairly well done, though welds could be better appearance wise. Like all proper trialers, the footpeg location is well rearward, virtually in line with the swinging arm pivot point.

Another plus is the addition of a lower mounting bracket that allows two mounting points for the rear damper units. This allows a rider to change his fork angle from 26.5 to 28 degrees by altering the angle of the rear dampers. However, the fork angle is still fairly steep, and on severe dropoffs the GRM has a tendency to want to do a front loop. The rider must compensate for this trait by putting as much of his weight rearward as is possible. Naturally, this is disconcerting for the rider and it makes the GRM somewhat more tricky in difficult sections.

Lortunately, the GRM is blessed with excellent balance characteristics and suspension, which is a great big portion of the basics. An experienced rider will have no trouble snaking his way around extremely tight turns and obstacles, with nothing on the machine hindering his movements. In fact, the only item preventing perfect trials rider position is the handlebars, which are much too flat to be right. But, since many trials riders make a switch to Renthal alloy bars anyway, it’s not too big a thing.

Our test machine was equipped with Betor forks and rear dampers, but in the future all models will be coming through with Boge rear units. This is one area of the bike’s performance that simply could not be faulted. In every type of trials section we could find or make up, the cushioning units worked superbly. Over rocks, drop offs...you name it, the units did their job. It was interesting to note that the Betor rear dampers were using up most of their travel on especially severe jolts. This allowed the rear tire to make contact with the underside of the rear fender on more than one occasion. But the Betors still had some stroke left in their travel, so it was not a case of them bottoming and allowing the tire contact. Rather, it was a case of a rear fender designed with less than ample clearance for such instances.

In any trials event a rider can get himself into some pretty ticklish situations; some require that the rider physically throw the machine one way or another to get through. That is why a trialer is light, to make it as easy as possible on the guy who is holding on with white knuckles. The GRM is in a bad position in this respect, since it’s a good 10 lb. heavier than the heaviest serious trialer we can think of. Ten pounds does not sound like too awful much, but after a day’s event where perhaps 36 sections have been traveled through, it makes a noticeable difference.

The main reason the GRM picks up so much weight is the extensive use of steel on most of the component parts. Items like wheel rims, spokes, sprockets, pedals and assorted bits and pieces really add up. The substitution of aluminum alloy for these parts would put the GRM down in the weight class where it belongs, but that is easier said than done.

Seems as though Mexico produces little in the way of alloy materials; that means that most would have to be imported from another country. Mexico, however, has laws that allow just 20 percent of component parts to be imported to manufacture a specific item, in this case a motorcycle. Since Grapevine is already exporting to Mexico the chrome moly tubing used in the GRM frame, there isn’t much left he can ship them. Twenty percent of the machine is already produced outside of Mexico. So steel it is.

By using a one-piece fiberglass tank/seat combination, some weight is saved, and a fiberglass rear fender does likewise. But at the front, a steel fender finds its way into the scene, so the GRM is a win some, lose some proposition. And again, even though the fiberglass saves pounds, the flexibility of the components fitted to the GRM is nil, so they won’t be too hard to damage in a fall. A plus is an impregnated maroon finish that is hard to scratch, and the 1.5-gal. fuel capacity is more than enough for any trials loop we’ve ever seen. Trialer seats are usually small and the GRM follows tradition, though its seat is one of the more comfortable ones we’ve sampled on a machine of this sort.

The 215cc piston-port Single fitted to the GRM will automatically place it in the 250 class, where trials events have specific displacement divisions. Most of the time in the U.S., however, everyone is grouped together, regardless of the size of their machine. But that’s not really the point here. The problem is that the GRM is heavier than the rest of the 250 trialers, and yet barely has the power output of a mediocre 175.

Moto Islo rates the unit at 18 bhp, but we can’t help but wonder after a ride if perhaps a decimal point has been misplaced. There is nothing particularly exciting about the engine’s basic design or construction, so the power output really doesn’t surprise us. A cast iron cylinder is used with an aluminum head, and side cases are sand castings, while main crankcases are die cast.

A 26mm Mikuni carburetor supplies fuel and spark is provided by an Italian Dansi magneto and components. Lighting coils are also fitted since lights are standard equipment, though they must be installed by the owner if he wishes. The engine starts easily in spite of the fact that the left footpeg limits the crank travel, an indication that the Dansi unit puts out a healthy spark. The kickstarter shaft also fouls the rider’s boot when he’s looking for the brake pedal, an item that requires considerable rethink.

Engine vibration is acceptably low, right up to maximum rpm, and the unit is mechanically quiet at the same time. An Xdusor spark arrester/silencer unit attaches to the end of the exhaust pipe, but it’s somewhat on the loud side, besides being rather large and more prone to damage. Primary drive is via single-row chain to a healthy clutch unit which, unfortunately, cannot be recommended too highly. It doesn’t seem to disengage completely, and if the rider adjusts it so it doesn’t drag, clutch slip occurs.

The transmission is strange in that it’s a four-speed unit, when the rest of the trialers are using five; but the shifting is smooth, and got more so as the miles piled up. Gear spacing, however, is peculiar. Low and second are fairly close together, which is the way it should be. But then comes a big jump to third, and fourth is again close. Most trialers have the first three gears close together with a slight jump for fourth and a big jump to high. The gear shift lever is a crude looking affair, but the important thing is that it’s well out of the way and shouldn’t snag on obstacles too easily.

Controls are set up much the same as other trialers, but clutch lever pressure is high and the effort required to squeeze the front brake lever is ridiculous. And as we said before, the kick start lever interferes with the operation of the rear brake pedal, so basically most of the control devices are unsatisfactory.

Also, after all that effort and trouble to apply the brakes, nothing much happens once you do. These are some of the poorest brake units we’ve ever sampled. Granted, trialers don’t need the stopping ability of a road racer, but it’s nice to know you can stop if need be! The GRM’s front brake is almost totally useless, and the rear one isn’t much better. This means that when a rider is traveling between sections at higher speeds on the loop of an event, he will have his hands full slowing down for a steep downhill, or another rider, and so forth. The brakes heat up rapidly, which only adds to the problem. The brakes could be improved a bit if the owner wanted to take the time to pull them apart and make a few modifications, but that really shouldn’t be necessary.

The lack of power, especially at low rpm, makes the GRM difficult to ride because it’s hard to get the front end up to clear an obstacle. The rider has to really give the bars a yank and hope for the best. There are also sections where a rider must pivot on his foot and pull the front end up and around to make an especially sharp turn. This is almost an impossibility on the Trialsmaster, due to the weight and lack of bottom end “grunt.”

GRM

ISLO

$895

The skid plate is like a bad joke, made from fiberglass and shaped to catch on everything in sight. Yet, they turn around and fit an excellent chain tensioner and cush drive for the rear hub to smooth power impulses; the GRM is full of contrasts such as this.

Whether or not the Trialsmaster gets straightened out remains to be seen, but as the machine presently stands, it’s the parody of the trials world.

View Full Issue

View Full Issue