THE SERVICE DEPT

JODY NICHOLAS

SQUEAKY DISC BRAKES

Recently I purchased a 1971 Honda CB450 K4 from my local dealer.

After approximately 500 miles, the front brake (hydraulic disc) began to squeak, at which time I asked the dealer about the problem. He said, “Wait until 1000 miles when your first service is due and we will take care of it then."

By the time the bike had 1000 miles on it the squeak was really pronounced. At this time I asked the dealer to correct the problem. I was told that all of the hikes with disc brakes had this problem and that, more or less, I had bought a very squeaky front brake along with the hike.

The dealer told me there was one thing I could do to eliminate the squeak, and that was to apply kerosene to the brake pads, and he said this is what the factory recommended to do to prevent squeaking.

I find it difficult to believe that something such as kerosene, which contains a considerable amount of oil, could safely be applied to brakes. I find it even more difficult to believe that the factory does such a thing.

My (piestion is, could it he possible that this is the recommended procedure? If so, would you please explain why, and if not, would you he able to recommend what can he done to correct this problem.

S.E. Schell Sebastopol, Calif.

The squeak of the front brake on many Hondas is annoying, and the factory is working on a cure for the problem. One dealer has found that careful alignment of the brake puck holders using the spring-loaded adjustment screw provided stops the squeak. Try adjusting the puck holders to give between 0.008 and 0.010 in. between each puck and the disc.

If this doesn’t cure the squeak, disassemble the puck holders and check for a small rock imbedded in the puck material. In no case should kerosene be applied to the brake pads, as the oil will become imbedded into the friction material and cause reduced braking efficiency and glazed pads.

As a last resort, try installing new pucks and align them carefully right away. (Continued on page 24)

Continued from page 22

SPARK PLUGS

I’m picking up a Kawasaki 175b' in due course and find that there are two holes drilled in the head for extra spark plug or compression release. First, does a “hotter ” plug provide more power for hillclimbing, etc.? If so, can you recommend a “hotter” plug or, if you can’t promote a particular company, could you give me a description, i.e., composition, stock number or type?

Secondly, what exactly is the function of a compression release mechanism? I understand that it is relative to braking in some way.

Gerald Jngley Hal timore, Md.

The “hot” or “cold” designation of a spark plug doesn’t mean that the former will produce more power than the latter. Rather, it is how quickly the spark plug dissipates the heat produced by the combustion process to the cylinder head. Engine design and usage dictate what heat range spark plug will be required in any application.

A “hot” spark plug has a long insulator nose which retains heat to keep carbon burned off and thereby help prevent spark plug fouling. “Hot” plugs are used in low-speed applications, such as trials riding, whereas a “cold” plug is used for track and road racing, where large amounts of heat are created by high rpm engines. A “cold” plug dissipates its heat rapidly and is prone to foul if the engine is allowed to run too slowly.

For hillclimbing, you would need a spark plug one or two ranges “colder” than the recommended heat range.

A compression release is used as a brake, and operates to make the engine like an air pump. When the compression release is actuated, it opens a hole and allows air to be drawn in and then expelled, but the hole is so small in comparison to the piston size that the passing air is considerably restricted. Hence, the braking action.

(Continued on page 32)

Continued from page 24

Some machines, such as the Maico 400, have a compression release installed as standard equipment, but the Maico’s release is used primarily to ease the starting chore.

RECTIFIER REPLACEMENT

The following is a suggestion to riders who need to replace their rectifiers:

When your rectifier goes bad, try replacing it with some silicon diodes. They are much less ex pensive, and they perform much better. Among their advantages are: 1) lower forward voltage drop, 2) greater resistance in the reverse direction than selenium, 3) longer life, and 4) ability to withstand greater heat.

They can be bought at any radio parts store such as Allied-Radio Shack (who were formerly Allied Radio and Radio Shack). The units I recommend come two to a package, and cost 69 cents for the two. You’ll need four. Ask for stock number 276-B-1142. These are rated at 100 peak inverse volts as a margin of safety. If the 100-volt units are not in stock, you can go higher without harm. They are also available in 200 and 400 PIV (they cost more, though). They are rated at 3 amps each, which should be sufficient.

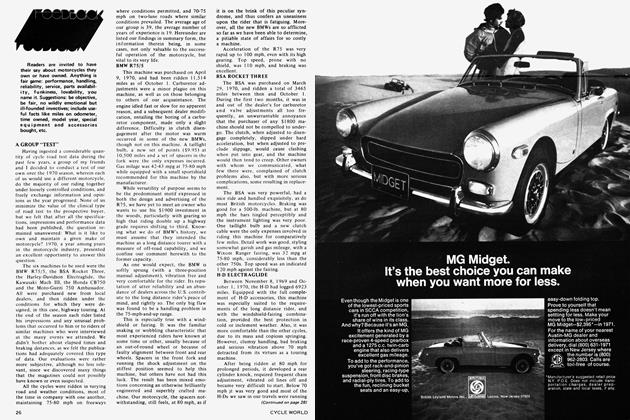

Wire them as shown in the following diagram:

Illustration (b) shows how to identify the polarity of the diode.

The diodes can be assembled on a small piece of perf-board or printed circuit board as desired.

If charging current does exceed 3 amps, parallel all four diodes with four other diodes in the same direction! Installing them in reverse could cause the circuit to pass A C.

These diodes are much cheaper than going to your neighborhood motorcycle shop and buying a selenium rectifier; however, they will give much better service.

Douglas Hoff Vacaville, Calif.

You are correct about the benefits of silicon diodes, and your method of using four of the Allied-Radio Shack’s number 276-B-1142 units would be right, except for the fact that in the circuit you propose, the 3-amp rating of each diode would not change, due to the wiring of the bridge, and your total capacity would still only be 3 amps. And the diodes may not break down at the same load, which would put more stress on the one(s) breaking down later. On a BSA or Triumph Twin, the minimum DC output from the rectifier at 3000 rpm should be no less than 9.5 amps! On the CB350 Honda, for example, the maximum charging current at 10,000 rpm is in the neighborhood of 4 amps, which would be safe for your system.

We suggest a single Motorola diode bridge, model number MDA 990-3, which would preclude having to mount four diodes on a piece of circuit board that could be damaged by vibration. The Motorola unit has a PIV rating of 200 volts, a continuous conduction current (steady state current) rating of 25 amps and a surge current capability of 300 amps! With an overload capacity like that, the unit should last forever.

With a retail price of $4.80 from most industrial electronic distributors, the Motorola diode is considerably less expensive than either the Lucas selenium rectifier ($12.60) as used on the large BSA and Triumph Twins, or the Honda rectifier, as used on the CB450 models, which sells for $9.20.

The Motorola diode features a single bolt mounting, and it should be attached securely to the frame, or at least should be grounded if it’s attached to plastic or some other poor conductor of electricity. It will remain operationally stable at temperatures well in excess of 100 degrees centigrade (212 degrees fahrenheit).

EXHAUST CLEANUP REVISITED

In the course of reading your suggestions on “Exhaust Clean-Up,” in the Service Dept., May issue, may I offer several alternative suggestions as substitutes for caustic soda (sodium hydroxide), and a few precautions. Sodium hydroxide (or caustic soda) is, or can be, very messy in the concentration range of 2 oz. to 32 oz. per quart of water. Dilute solutions are better cleaners than the concentrated solutions. Shoot for 2 to 4 oz. of sodium hydroxide per quart of water. Many of the drain cleaners contain sodium hydroxide as the active ingredient. Other alternatives are washing soda, sodium carbonate, and tri-sodium phosphate, which is one of the principle ingredients in Calgon electric dishwasher detergent.

Do not use any of the above compounds in aluminum containers. Strong bases or caustic attack aluminum with the formation of hydrogen gas which could surprise the unwary with an explosion. A steel 100-lb. (?) grease drum would be a good choice for a container with a fire built under the bottom outdoors. Take caution about open fires and outdoor burning regulations.

Torching out the accumulated carbon can be a very time consuming task; I’ve been putting it off. Has anyone tried building a charcoal fire around the baffle tubes for several hours? This type of fire would not be as tricky to control as an oxy-acetylene torch and not as apt to introduce strain or permit bending due to the less concentrated heat.

In handling any of the above compounds used for cleaning mufflers, etc., it would be an excellent idea to put the helmet on the head with the face shield, full face shield, attached. Strong bases in the eyes are many times more unpleasant than acids. Wear gloves, preferably rubber, while handling these cleaners and the cleaned muffler, and use plenty of water to thoroughly rinse everything when finished.

David C. Taylor, Ph.D Slippery Rock, Pa.

Thank you very much for your interest and concern. The dangers of caustic soda are very real indeed, and most brands have warnings printed on the labels.

Your idea of using a charcoal fire to heat the baffle tubes is certainly a good one. All readers having tips or ideas such as Dr. Taylor’s are urged to send them in to the Service Department.

View Full Issue

View Full Issue