THE SERRVICE DEPT

JODY NICHOLAS

CT-1 ELECTRICS

This is in answer to switch hitter, Charles Jacob Jr. from Rocky Ford, Colo., who has battery problems with his CT-1.

I also have a CT-1 Enduro, and the battery is really too small for the machine. I’ve done a considerable amount of checking on the same problem, and can state that the rear stoplight operates on both the generator and the battery.

Proof of this is when / ride the dirt in close quarters, using the brake constantly. The stoplight is bright at the start, but slowly begins to fade. This is not the case during normal road riding, as I believe the battery takes a charge.

There is nothing radically wrong, but I’m thinking of having another CT-1 battery placed in series for added life. There appears to be enough room in the compartment. That is, if the increased amperage does not have an adverse effect.

Carmine Bricchi West Babylon, N. Y.

Thank you for taking time to send in your comments on the Yamaha CT-1. We are publishing your letter in hopes that other readers might use the information. However, if you did install another battery to increase the length of time the light will burn before it begins to grow dim, it would have to be wired in parallel with the first battery and not in series, which would double the voltage.

COMMANDO GRIPES

All questions refer to a '70 Norton Commando Roadster purchased new in June 19 70. After 4500 miles and three times to the shop to have it adjusted, I have had four clutch plates replaced because they were glazed. Now the bike is starting to do the same thing again after 6000 miles, or 1500 miles after the plates were installed. Could you possibly recommend a solution to this, or should / have a Barnett racing clutch installed?

Secondly, there is a bad vibration between 1000 to 2000 rpm. Since this

has Isolastic mounting, where does the vibration come from and how might it be cured?

Thirdly, I keep stripping kickstarters because of vibration. Would it be best to have the gearbox dismantled and have a key way cut in the shaft? Also I have heard about a new 35-mm Lake carburetor with only one knob for adjustment. Could you explain how this works and how it is superior to the A mals on my bike now. Also, would they mount on my intake manifolds? What modifications would you recommend to the engine, bearing in mind that I take this bike on long rides and

need reliability? D. . „ ,, ,,

Rick Pershell

Carbondale, III.

The Norton Commando clutch is one of the best, and should last much longer than 4500 miles. 1 suspect that insufficient clearance between the clutch pushrod and actuating arm, which is located just inside the outer gearbox cover on the right side of the machine, is causing the trouble. If there is not enough clearance there, and at least 3/16 in. of free play between the clutch lever and its inner casing, the clutch pressure between the plates could be lessened to the extent that slippage occurs, leading to glazed friction plates. Barnett clutch plates are available for the Commando and give excellent results.

Norton-Villiers Corp. has found that 5 oz. of SAE 20 oil is plenty to lubricate the primary chain, and caution should be used not to exceed that amount. Drain your primary chaincase completely and add 5 oz. of oil. This will reduce the possibility of oil coming in contact with the clutch plates and causing slippage.

Vibration at low engine speeds is a characteristic of the Commando and helps take advantage of the Isolastic engine suspension system. The flywheel balance factor is drastically different from conventionally mounted vertical Twins (52 percent against 84 percent for a Norton Atlas, for example), so that it will vibrate at low speeds, and not in the 3500-5500-rpm range where most riding is done. Shims can be added or removed from the suspension units to vary their movement, and the vibration’s severity, but the standard number seems to be quite correct.

You neglected to mention which part of the kickstarter strips, but 1 suspect that it was the shaft and not the crank itself. There were a few shafts that were made too soft and had a tendency to strip. A replacement shaft should cure the problem. There is a fine line between having the shaft too soft, which will cause it to strip, and too hard, which could cause it to shatter while cranking the engine. Norton-Villiers has also found that some owners mount their kickstarter levers too far forward.

(Continued on page 40)

Continued from page 38

This often causes the pawls to engage because the rider’s calf presses on the lever and causes it to move rearward while he is riding.

The standard 30-mm Amal Concentric carburetors have proven to be large enough, even for racing. Once tuned, they have little tendency to get out of adjustment. For the smoothest performance and best reliability, it would be best to leave your machine standard, and maintain it in good tune.

YAMAHA KLUNK

/ own a Yamaha 650 and. until recently (at 3000 miles), was very happy with its performance. When the dutch is engaging in first gear, the transmission lets out a very noticeable klunk. I've spoken to my dealer, and as far as he cati tell, every 650 Yamaha made makes this grinding noise. He explained that until something goes wrong he can 't do a thing about it.

I have a suspicion that it might have to do with the spring-loaded gears in back of the dutch housing. But / can't explain why it won't make the noise when the engine is cold. I would apprec ia t e any s i igges t ion s.

Mark Roche Redwood City, Calif.

Your noise is quite common to the Yamaha 650 XS1 and is attributed to both the six cushion springs in the clutch hub and to the normal slack in the transmission’s components. So far, no one seems to have had any trouble with the Yamaha transmission, but the noise is somewhat annoying.

Yamaha International has now changed their engine/transmission oil recommendation from SAH 30 to either SAH 20W-40 or SAH 40-weight oil. I'he thicker oil tends to reduce the gear noises, and provides better protection.

BMW CARB CURE

As the proud owner of a new BMW R75/5 l have experienced considerable difficulty with both carburetors, and thought my findings might be useful to other BMW owners. As far as l know, there are no service bulletins out covering this trouble.

The trouble is that the needle and the seat in the carburetors are not cutting off the gasoline flow completely or regulating it properly. The following is a step-by-step method for completely eliminating the problem. If you have the proper tools, the entire job can be done in about 10 minutes per carburetor.

1. Remove carburetor float bowl.

2. Remove carburetor float hinge pin. This"'pin is knurled on one side and

(Continued on page 42

Continued from page 40

is pressed in. It must be removed in the opposite direction from which it was installed. This can be determined by a close examination of both ends of the pin. The end which went in first has a short, sharp taper on it. Use a suitable punch and carefully tap the pin out. Be careful not to drop the float or the needle. Notice that the needle has a spring-loaded ball on the end which contacts the float.

3. Obtain an 8 in. length of %-in. diameter copper tubing. Make sure that one end of the tubing is square and free from burrs.

4. Install the needle in the carburetor body and place the square end of the copper tubing on the bottom of the needle. Using a small hammer, tap once lightly on the bottom of the copper tubing.

5. Reassemble the carburetor and check at least 10 minutes for flooding. On my machine, I used a Swiss file to remove the knurling on the hinge pin for possible future removal. The pin will still be finger tight in the carburetor body. If the carburetor still floods,

repeat the procedure.

Robert Hayden Dallas, Tex.

Thank you very much for your letter. Even such a seemingly minor.problem can cause a machine to run erratically at low speeds, and no amount of adjustment will completely cure it. Readers who own different machines may find it worthwhile to perform similar modifications on their carburetors.

MOTORCYCLE SCHOOLS

I have been trying to secure employment as a motorcycle mechanic for several months without success. Since my experience has been limited to working on my own machines, I can understand why dealers would be hesitant to hire would-be mechanics.

My question, which no dealer whom I have approached can answer, is: where can I get shop experience that will render me an experienced and employable mechanic? I am willing to relocate anywhere in the United States to receive whatever training available. Any information you can send me will be greatly appreciated.

Ray Richter Bartlesville, Okla.

Due to Mr. Richter’s letter, and many just like it, I’ve decided to expand on the answer to Isiah Charleston’s letter which appeared in the Service column, August issue.

There are two schools in the Los Angeles area which offer a course inmotorcycle mechanics in their curriculum. Los Angeles Trade Technical College, 400 W. Washington Blvd., Los Angeles, CA 90015, offers a two-year program. Pat Maloy is the senior instructor. The West Valley Occupational Center, 6200 Winnetka, Woodland Hills, CA 91364 is the other. They offer a 20week semester course, which may be attended twice to complete a full school year. Marty Dickerson is the man to contact there.

Both of these schools have waiting lists which are quite long. If any reader is interested in attending, it would be wise to write for the particulars as soon as possible.

Schools in states other than California offering motorcycle mechanics are not known to me. The best way to find out where they are is to write to that state’s department of education, which is usually located in the same city as the capitol.

Motorcycle mechanics are scarce . . . the field is wide open! [Ö]

View Full Issue

View Full Issue

More From This Issue

-

Departments:

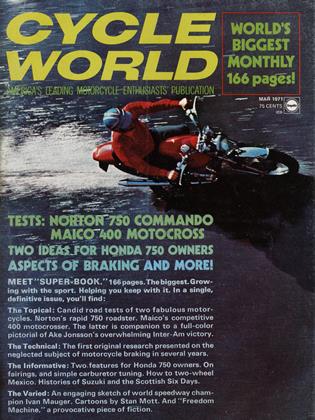

Departments:Round Up

March 1971 By Joe Parkhurst -

Letters

LettersLetters

March 1971 -

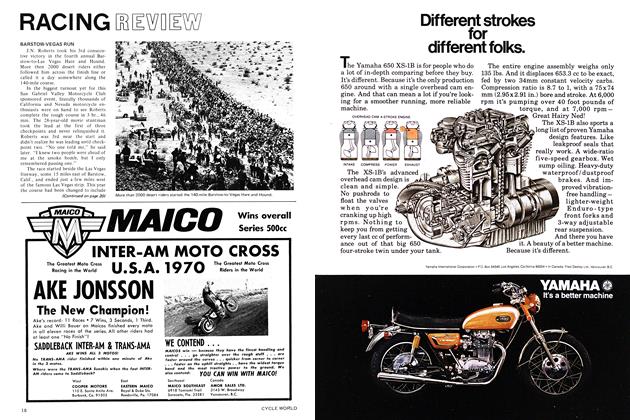

Departments:

Departments:Racing Review

March 1971 -

Departments:

Departments:The Scene

March 1971 By Ivan J. Wagar -

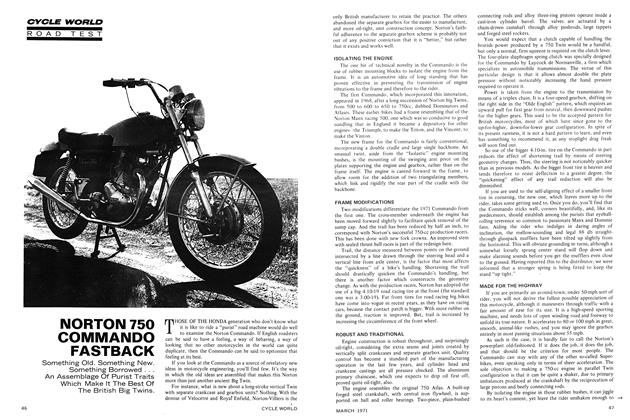

Cycle World Road Test

Cycle World Road TestNorton 750 Commando Fastback

March 1971 -

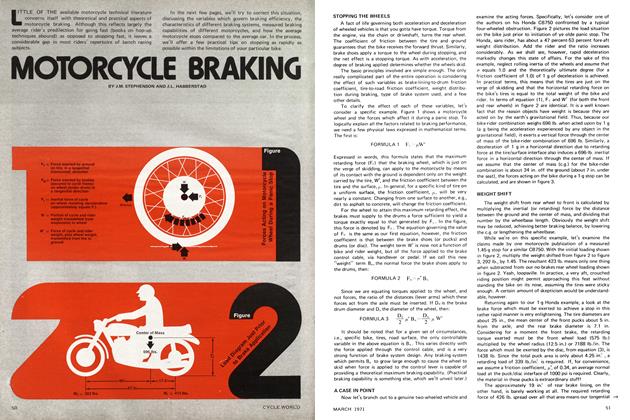

Technical Feature:

Technical Feature:Motorcycle Braking

March 1971 By J.L. Habberstad, J.M. Stephenson