MOTORCYCLE BRAKING

LITTLE OF THE available motorcycle technical literature concerns itself with theoretical and practical aspects of motorcycle braking. Although this reflects largely the average rider's predilection for going fast (books on hop-up techniques abound) as opposed to stopping fast, it leaves a considerable gap in most riders' repertoire of bench racing subjects.

In the next few pages, we'll try to correct this situation, discussing the variables which govern braking efficiency, the characteristics of different braking systems, measured braking capabilities of different motorcycles, and how the average motorcycle stops compared to the average car. In the process, we'll offer a few practical tips on stopping as rapidly as possible within the limitations of your particular bike.

J.M. STEPHENSON AND J.L. HABBERSTAD

STOPPING THE WHEELS

A fact of life governing both acceleration and deceleration of wheeled vehicles is that you gotta have torque. Torque from the engine, via the chain or driveshaft, turns the rear wheel. The coefficient of friction between the tire and ground guarantees that the bike receives the forward thrust. Similarly, brake shoes apply a torque to the wheel during stopping, and the net effect is a stopping torque. As with acceleration, the degree of braking applied determines whether the wheels skid.

The basic principles involved are simple enough. The only really complicated part of the entire operation is considering the effect of such variables as brake-lining-to-drum friction coefficient, tire-to-road friction coefficient, weight distribution during braking, type of brake system used, and a few other details.

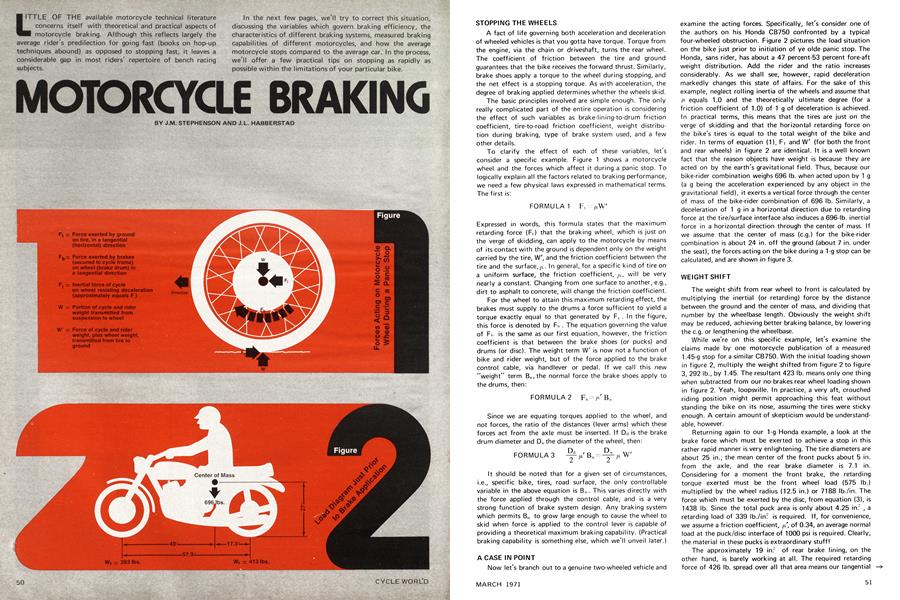

To clarify the effect of each of these variables, let's consider a specific example. Figure 1 shows a motorcycle wheel and the forces which affect it during a panic stop. To logically explain all the factors related to braking performance, we need a few physical laws expressed in mathematical terms. The first is:

FORMULAI F, >W'

Expressed in words, this formula states that the maximum retarding force (F,) that the braking wheel, which is just on the verge of skidding, can apply to the motorcycle by means of its contact with the ground is dependent only on the weight carried by the tire, W', and the friction coefficient between the tire and the surface,/t. In general, for a specific kind of tire on a uniform surface, the friction coefficient, will be very nearly a constant. Changing from one surface to another, e.g., dirt to asphalt to concrete, will change the friction coefficient.

For the wheel to attain this maximum retarding effect, the brakes must supply to the drums a force sufficient to yield a torque exactly equal to that generated by F, . In the figure, this force is denoted by Fi,. The equation governing the value of Fi, is the same as our first equation, however, the friction coefficient is that between the brake shoes (or pucks) and drums (or disc). The weight term W' is now not a function of bike and rider weight, but of the force applied to the brake control cable, via handlever or pedal. If we call this new "weight" term B„,the normal force the brake shoes apply to the drums, then:

FORMULA 2 F„ = B„

Since we are equating torques applied to the wheel, and not forces, the ratio of the distances (lever arms) which these forces act from the axle must be inserted. If D,i is the brake drum diameter and Du the diameter of the wheel, then:

FORMULA 3 -yV Bn = y~/x W'

It should be noted that for a given set of circumstances, i.e., specific bike, tires, road surface, the only controllable variable in the above equation is B„. This varies directly with the force applied through the control cable, and is a very strong function of brake system design. Any braking system which permits B„ to grow large enough to cause the wheel to skid when force is applied to the control lever is capable of providing a theoretical maximum braking capability. (Practical braking capability is something else, which we'll unveil later.)

A CASE IN POINT

Now let's branch out to a genuine two-wheeled vehicle and

examine the acting forces. Specifically, let's consider one of the authors on his Honda CB750 confronted by a typical four-wheeled obstruction. Figure 2 pictures the load situation on the bike just prior to initiation of ye olde panic stop. The Honda, sans rider, has about a 47 percent-53 percent fore-aft weight distribution. Add the rider and the ratio increases considerably. As we shall see, however, rapid deceleration markedly changes this state of affairs. For the sake of this example, neglect rolling inertia of the wheels and assume that /x equals 1.0 and the theoretically ultimate degree (for a friction coefficient of 1.0) of 1 g of deceleration is achieved. In practical terms, this means that the tires are just on the verge of skidding and that the horizontal retarding force on the bike's tires is equal to the total weight of the bike and rider. In terms of equation (1), Ft and W' (for both the front and rear wheels) in figure 2 are identical. It is a well known fact that the reason objects have weight is because they are acted on by the earth's gravitational field. Thus, because our bike-rider combination weighs 696 Ib. when acted upon by 1 g (a g being the acceleration experienced by any object in the gravitational field), it exerts a vertical force through the center of mass of the bike-rider combination of 696 Ib. Similarly, a deceleration of 1 g in a horizontal direction due to retarding force at the tire/surface interface also induces a 696-lb. inertial force in a horizontal direction through the center of mass. If we assume that the center of mass (c.g.) for the bike-rider combination is about 24 in. off the ground (about 7 in. under the seat), the forces acting on the bike during a 1-g stop can be calculated, and are shown in figure 3.

WEIGHT SHIFT

The weight shift from rear wheel to front is calculated by multiplying the inertial (or retarding) force by the distance between the ground and the center of mass, and dividing that number by the wheelbase length. Obviously the weight shift may be reduced, achieving better braking balance, by lowering the c.g. or lengthening the wheelbase.

While we're on this specific example, let's examine the claims made by one motorcycle publication of a measured 1,45-g stop for a similar CB750. With the initial loading shown in figure 2, multiply the weight shifted from figure 2 to figure 3, 292 ib., by 1.45. The resultant 423 Ib. means only one thing when subtracted from our no-brakes rear wheel loading shown in figure 2. Yeah, loopsville. In practice, a very aft, crouched riding position might permit approaching this feat without standing the bike on its nose, assuming the tires were sticky enough. A certain amount of skepticism would be understandable, however.

Returning again to our 1-g Honda example, a look at the brake force which must be exerted to achieve a stop in this rather rapid manner is very enlightening. The tire diameters are about 25 in., the mean center of the front pucks about 5 in. from the axle, and the rear brake diameter is 7.1 in. Considering for a moment the front brake, the retarding torque exerted must be the front wheel load (575 Ib.) multiplied by the wheel radius (12.5 in.) or 7188 lb./in. The force which must be exerted by the disc, from equation (3), is 1438 Ib. Since the total puck area is only about 4.25 in: , a retarding load of 339 lb./in: is required. If, for convenience, we assume a friction coefficient, ft, of 0.34, an average normal load at the puck/disc interface of 1000 psi is required. Clearly, the material in these pucks is extraordinary stuff!

The approximately 19 in: of rear brake lining, on the

other hand, is barely working at all. The required retarding force of 426 Ib. spread over all that area means our tangential

loading is only 22 psi, and even assuming a // of only 0.34 again, the normal load is only 65 psi. Stopping full-on all the time is great for rear brake life.

In this section then, we saw that, given identical tires (so that the friction coefficient is a constant), all motorcycles have the same theoretical braking capability. Practical experience reveals, however, that regardless of theory, some motorcycles stop a lot better than others.

MOTORCYCLE BRAKES

Motorcycle brakes generally come in three configurations, single-leading shoe, double-leading shoe, and disc. Each of these types have inherent advantages and disadvantages, which should govern the choice of brakes for any particular machine.

Before considering the two different internal expanding brake configurations, let's first look at the forces acting on one brake shoe inside a rotating brake, as shown in figure 4. The dimensions shown were chosen largely to simplify the analysis, but they don't differ greatly from those on many machines being sold. The brake shoe is assumed to be of unit width (one inch in this case) and the loading of the brake shoe surface is assumed uniform. This latter assumption neglects such important factors as brake shoe and drum distortion, uneven brake shoe wear, and "bell-mouthing" of the drum under stress. For our purposes the assumptions approximate the real case sufficiently closely.

The unit normal loading of the brake shoe, b„, is simply our friend from equation (3), B„, divided by the braking area. Similarly, f,,, is just the Fh from equation (2), divided by the same area.

The reason for the relatively high efficiency of leading shoe brakes like that in the figure may be explained as follows. Application of a braking force by the rider results in a unit normal loading, b„, which may be easily calculated if the wheel is not turning. For the configuration shown in figure 4, an input force of 200 lb. yields an average unit static loading of 58 psi. However, if the wheel is turning or trying to turn, a frictional force is induced at the surface of the shoe, and the value of b,, is magnified substantially. This is true because the tangential load considerably magnifies the force exerted by the pivot pin, F,,, which acts to hold the shoe in place. The couple induced by these two forces must be offset by a corresponding increase in the value of b„. This increase is commonly referred to as "the degree of self-actuation," and is a true mechanical servo effect. As might be expected, for a given lining geometry, the magnitude of the multiplier effect depends only on the shoe-to-drum friction coefficient, //, and the pivot pin placement. The dramatic effect of friction coefficient on the brake self-actuation is shown in the following table:

friction coefficient 0.2 0.4 0.5 0.55 0.60 0.62 brake multiplier 1.5 2.8 5.1 8.5 29 infinite % self actuation 31 65 82 90 97.5 infinite

The infinite values listed for a friction coefficient of 0.62 are, of course, impossible to obtain, since the bike and rider part company at somewhat lower numbers.

The message from this little exercise makes a couple of interesting points. First, that self-actuation may very well be the average rider's best friend, is surely true up to a point. It permits factories to equip bikes with relatively low-coefficient, long-wearing brake linings while still permitting rather efficient brakes. Without self-actuation, the typical bike might be equipped with a Danforth anchor and strong line.

Secondly, a weekend road racer looking for more brakes for his pony, via stickier linings, had best employ some discretion. In practical terms, the breakdown of our equations at a // value of 0.62 signals that we've reached a point of

instability. The rider need only hit the brake lever once to shut things down for good. Releasing the lever has no effect, since positive feedback makes the system independent of the rider.

It might also be noted that unless the effect of such things as water and dirt on the linings can be verified, the average rider would be well advised not to approach the limit too closely. Although the maximum useable friction coefficient will vary somewhat depending on brake shoe geometry, the installation of linings with a coefficient over 0.5 should be followed by a fair amount of testing prior to use in competition.

The above information reveals the really important difference between single-leading shoe brakes and double-leading shoe brakes. All of the equations employed to obtain the above results are equally valid for a trailing shoe, except that the self-actuation feature now works against the rider. For a trailing shoe, our braking system which produced a static normal force of 58 psi may produce a force of only 25 psi for a friction coefficient of 0.5 (if the wheel is trying to turn). For a single-leading shoe system, with a p'of 0.5, the leading shoe provides 90 percent of the total stopping force during a panic stop. The same linings in a double-leading shoe system of the type shown in figure 6 provide 80 percent more total stopping force.

DISC BRAKES

Brake design work these days is going primarily into the area of front brakes, and the key word is disc. The most admirable quality of all disc brake systems, a vastly increased fade resistance, was first exploited by auto racers about 1954. By 1964, drum brakes on Grand Prix cars were ancient history, and a large share of European passenger cars were joining the trend. The if-we-didn't-start-it-it-ain't-no-good philosophy kept the devices generally unavailable on Detroit iron for a few more years, but capitulation was inevitable. The Lockheed double disc set-up, which became more or less available a few years ago, signaled the era of modern disc brakes for motorcycles. Lyster, Airheart, and others followed suit and the Honda CB750 and the new CB450 are now setting the pace. Capitulation by at least the heavyweight bike manufacturers is equally inevitable.

HOW A DISC BRAKE WORKS

Before discussing the advantages and disadvantages of discs, a glance at figure 7, a unit similar to that used by Honda, might be informative. As is shown, only one of the two pucks is actually forced against the disc by hydraulic fluid pressure on the piston! The other actually moves with the housing which pivots with the caliper unit on an arm attached to the support hinge on one fork leg. Compared to the fixed caliper arrangement, this system is much simpler, since a separate hydraulic piston for each puck is no longer required.

The systems operation is quite simple, since movement of a piston in the brake fluid reservoir (master cylinder) forces fluid into the pressure chamber, applying pressure to the back of the puck via the piston, and thence to the disc by surface contact with the front side of both pucks.

Since disc brakes are so simple, why haven't they been used before? For one thing, they require much higher unit loads than shoe brakes to achieve identical stopping torque. This translates into high force multiplication from the hand lever to the puck. A really strong grip might achieve a load at the handlebar of 100 lb., but the average individual is good for much less, say 50 lb. Control lever multiplication helps some, but in the Honda for example, our puck required an input load of over 2000 lb.

Accordingly, multiplication of perhaps 40 is required. All the mechanical gadgetry required to do this may be deleted if a hydraulic system is employed, since a small master cylinder piston combined with a large puck piston may give pretty hefty total force magnifications. For example, a 0.3-in. master cylinder piston diameter and a 2-in. puck piston diameter combine to give a ratio of 44:1, pretty close to what we need. By setting puck-to-disc clearance to a very small value (less than 0.010 in. for the CB750) the total amount of hydraulic fluid which must be pumped from the master cylinder is very small, and the required handlever travel may be minimized. Of course the hydraulic system requires machining to much closer tolerances than many manufacturers are accustomed to. And therein lies another reason discs haven't been used—cost.

Yet another reason concerns the lining material required. Standard shoe-type linings just won't do for puck material since these materials may operate at b,,values of about 300 psi, but not for long. One thousand psi would wear them down in nothing flat. That the required materials, whatever they contain, can be developed is clearly evidenced by Honda's experience.

THE NITTY GRITTY

While theoretical discussions are interesting, the way that brakes perform in day-to-day use is the really important thing. In general, riding habits should be tailored to the capability of the machine, and this is as true in the area of braking as in any other area.

To determine just how good brakes on the average motorcycle are, seven different machines were subjected to a series of maximum braking tests on a stretch of asphalt highway. Tests were run using the front brake only, the rear brake only, and both brakes. Test runs were made at an indicated 20 mph and an indicated 40 mph. The results were analyzed using corrected speedometer readings.

A solenoid-actuated dart gun was used to mark the point of first brake application. Stopping distance was then obtained by measuring from the dart impact point to the stationary motorcycle. At least two runs were made employing all combinations of variables, and those reported represent the best efforts. A summary of the results obtained is presented in Table I.

With the exception of the Honda CB350, which exhibited at all speeds and for all brake combinations the best performance, there appears to be no standout performer. There are a few additional considerations not apparent in the raw figures, which warrant some discussion.

The first regards the experimental scatter apparent between consecutive similar runs. Frequently, differences of 25-30 percent were observed. This confirms the fact that the results are a strong function of rider technique. Because the tests were performed primarily to determine "first stop" capability, adequate time was allowed between tests for cooling. On all bikes except the BSA, no fade was observed. However, after three 40-mph stops with the BSA, brake fade was very noticeable despite the rest periods. In addition, the maximum braking which could be obtained on this bike from 38.3 mph (40 mph indicated) was 0.64 g, an indication that brake fade was in fact occurring during the stop. The linings in this 1963 model were admittedly very hard and probably not up to current standards.

With this exception, no major decreases in stopping capability were observed between the slow and medium speed tests. A decrease in maximum CB350 deceleration from 1.1 g to something over 0.9 g was attributed mainly to increasing control difficulties under high speed-high g conditions. In

other tests using a similar CB350, deceleration rates of 1 g have been obtained at speeds of up to 50 mph.

The CB750 results are interesting because of the considerable interest which has surrounded the disc front brake. Although, as the author can attest, this set-up has virtually absolute fade resistance, the figures suggest that the average rider can probably not utilize the maximum capability inherent in this set-up. Front wheel lock-up can be obtained but tends to be most unnerving and is usually short-term.

THE BRICKWALL TROPHY

The relatively poor showing of the smaller bikes is attributable to two things. The first is the presence, on all of these bikes, of single-leading shoe brakes on both the front and rear wheels. As we previously saw, a double-leading shoe system on the front wheel is considerably superior for highway riding. It should be said, in defense of these bikes, that since they are used for everyday transportation and are from two to five years old, they may not reflect the capability of many of the lightweight bikes being sold today. And, of course, a primary constraint on the design of these bikes is cost, and a double-leading shoe system is more expensive.

This attention to cost-saving, in the area of poor quality cables, was the other primary reason, and also was a factor in the BSA results. An important feature of any front brake system is a control lever that retains some hand grip clearance during even a rather frantic yank. On all of these bikes, the control lever could be "pegged" prior to wheel lock-up, even after system adjustment. During the braking tests, this characteristic caused the controls to feel mushy.

After completion of the braking tests, one other group of tests was performed to determine how the results compared with the "theoretical maximum" braking rate described by equation 1. During these tests, performed only with the CB350 and CB750, a force gauge was used to measure the force required to drag the motorcycles over the test surface with the brakes locked. In this manner, the kinetic friction coefficient, //, was obtained. Both bikes equipped with the stock Bridgestone tires gave friction coefficients of about 1.16. The load required to start the bikes skidding was also measured, and the static friction coefficient obtained was about 1.2.

CONCLUSIONS

Now that we've examined braking from a theoretical standpoint and also run some tests to see how things really work, a few reasonably educated conclusions can be made.

First, our idealized equations really do describe what's practically possible under near perfect conditions, and are born out by the CB350 test results. The stopping rate of this bike approached the theoretically realistic maximum to within 5 percent. Rider judgement and control is an important variable and is attested to by the wide disparity between the theoretical CB750 capability and its performance. Visions of skidding along the ground with the front wheel locked up clearly tempered the rider's grip with undue prudence. The high mileage CB450 was apparently incapable of locking up the front wheel, despite its double-leading shoe system. All of the other bikes had a single-leading shoe system on front and all were incapable of lock-up.

As far as the best practica! panic stop is concerned, a few ideas need emphasis. A well known engineering principle states that, the coefficient of static friction is always higher than the coefficient of kinetic friction. Simply stated, it takes more force to start something sliding than to keep it sliding.

Continued on page 126

Continued from page 56

The difference between the measured static coefficient (1.2) and dynamic coefficient (1.16) bears this out. It is a small difference, which means that it is impossible for the average rider to determine accurately where the breakaway point is, and yet continuously brake in excess of the kinetic limit.

What does this mean insofar as technique is concerned? For one thing, it means that locking up the rear wheel is normally the most efficient procedure in a straight-line stop. The rear end may fishtail a bit, but at speeds up to 50 mph or so, the average rider should be able to maintain control.

As far as the front wheel is concerned, it means that lock-up may not trigger the instant disaster we all imagine. If the kinetic and static coefficients were exactly the same, the handling behavior of the bike would be the same immediately after the start of skidding as it was immediately before, again assuming a straight-line stop. The closer these are together, the smaller the variation. Rapidly locking and releasing the front brake probably provides maximum stopping in a reasonably controlled manner. In a turn, this same small difference means that rear wheel breakaway occurs gradually, with a bit of drift, giving the rider time to take corrective measures. But the extreme angle of lean in this situation may prove a problem in attempting a recovery. Friction coefficients in excess of 1.0 also reveal why motorcycle tires tend to be rather short-lived compared to the harder automobile tires, which typically have a coefficient of 0.67 to 0.85.

THE RIDER FACTOR

But back to braking. Completion of this series of tests leads the authors to believe that few riders are capable of completing a 1-g stop except under near ideal circumstances. The external stimuli provided by the extreme bike nose-dive and the personal discomfort resulting from the very noticeable loads (you gotta hang on!) probably add all the prudence necessary. So, unless you have a super-servo, doubleleading shoe brake on the front, don't be afraid to grab a handful of front brake during a pavement panic stop.

It is obviously very desirable to

(Continued on page 134

Continued from page 126

have some prior familiarity with the panic stop characteristics of your iron pony, at least dynamically, and possibly statically. To run a capability check, hook up a rope to the frame of your charger and the rear bumper of a friend's car and let him try to drag you a few feet with the brakes locked. The only essential precaution is to tie the rope below the center of gravity. If that front wheel continues to turn despite your best grip, our old friend B is an anemic sort, and equation No. 3 doesn't apply to you. A full-on stop on clean dry pavement means noholds-barred.

Finally, how does the average motorcycle stop compared to the average car? If you're a tailgater and read through all the previous material just to get this information, you're liable to be disappointed. Referring to Consumer Reports' tests for the past year on a wide variety of cars, the maximum deceleration rates for most cars are quite similar to those for most bikes, 0.67 to 0.85 g's. The major difference here is that braking to the point of a four-wheel skid is relatively easy for most auto systems, so that the above figures represent almost maximum capability as defined by equation No. 3. The motorcyclist, on the other hand, seldom locks up the front wheel, and therefore has some room for improvement. Motorcycle tires are just plain stickier than car tires, but not all bikes can use this fact to best advantage.

To summarize, motorcycle braking capability is a widely variable function of machine and rider characteristics. The most recent crop of motorcycles, through improved system design and lining material, make stopping at relatively high deceleration rates easier than ever before. However, under these higher rates, the rear wheel assumes an ever diminishing portion of the load, and the front wheel brakes become most important.

A familiarity with front wheel ''feel'' during braking becomes really essential. The average motorcycle in good condition with an average rider should be able to stop about as fast as most of the cars on the road today. A fairly experienced rider with a competent machine and a practiced technique can 'Stop somewhat faster than the best, but not every time. [Ö]