THE MEXAWOP EXPRESS

D. RANDY RIGGS

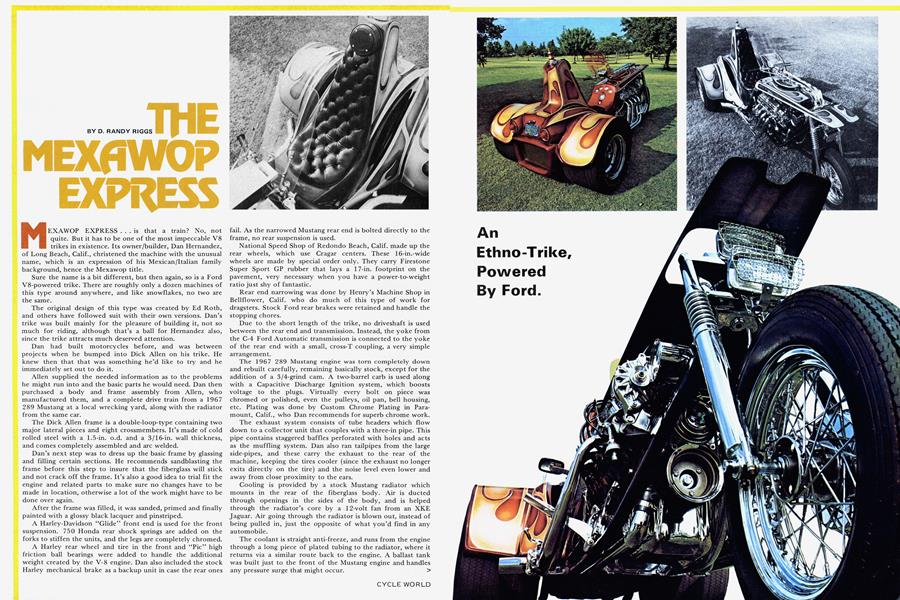

MEXAWOP EXPRESS ... is that a train? No, not quite. But it has to be one of the most impeccable V8 trikes in existence. Its owner/builder, Dan Hernandez, of Long Beach, Calif., christened the machine with the unusual name, which is an expression of his Mexican/Italian family background, hence the Mexawop title.

Sure the name is a bit different, but then again, so is a Ford V8-powered trike. There are roughly only a dozen machines of this type around anywhere, and like snowflakes, no two are the same.

The original design of this type was created by Ed Roth, and others have followed suit with their own versions. Dan's trike was built mainly for the pleasure of building it, not so much for riding, although that's a ball for Hernandez also, since the trike attracts much deserved attention.

Dan had built motorcycles before, and was between projects when he bumped into Dick Allen on his trike. He knew then that that was something he'd like to try and he immediately set out to do it.

Allen supplied the needed information as to the problems he might run into and the basic parts he would need. Dan then purchased a body and frame assembly from Allen, who manufactured them, and a complete drive train from a 1967 289 Mustang at a local wrecking yard, along with the radiator from the same car.

The Dick Allen frame is a double-loop-type containing two major lateral pieces and eight crossmembers. It's made of cold rolled steel with a 1.5-in. o.d. and a 3/16-in. wall thickness, and comes completely assembled and arc welded.

Dan's next step was to dress up the basic frame by glassing and filling certain sections. He recommends sandblasting the frame before this step to insure that the fiberglass will stick and not crack off the frame. It's also a good idea to trial fit the engine and related parts to make sure no changes have to be made in location, otherwise a lot of the work might have to be done over again.

After the frame was filled, it was sanded, primed and finally painted with a glossy black lacquer and pinstriped.

A Harley-Davidson "Glide" front end is used for the front suspension. 750 Honda rear shock springs are added on the forks to stiffen the units, and the legs are completely chromed.

A Harley rear wheel and tire in the front and "Pic" high friction ball bearings were added to handle the additional weight created by the V-8 engine. Dan also included the stock Harley mechanical brake as a backup unit in case the rear ones fail. As the narrowed Mustang rear end is bolted directly to the frame, no rear suspension is used.

National Speed Shop of Redondo Beach, Calif, made up the rear wheels, which use Cragar centers. These 16-in.-wide wheels are made by special order only. They carry Firestone Super Sport GP rubber that lays a 17-in. footprint on the pavement, very necessary when you have a power-to-weight ratio just shy of fantastic.

Rear end narrowing was done by Henry's Machine Shop in Bellflower, Calif, who do much of this type of work for dragsters. Stock Ford rear brakes were retained and handle the stopping chores.

Due to the short length of the trike, no driveshaft is used between the rear end and transmission. Instead, the yoke from the C-4 Ford Automatic transmission is connected to the yoke of the rear end with a small, cross-T coupling, a very simple arrangement.

The 1967 289 Mustang engine was torn completely down and rebuilt carefully, remaining basically stock, except for the addition of a 3/4-grind cam. A two-barrel carb is used along with a Capacitive Discharge Ignition system, which boosts voltage to the plugs. Virtually every bolt on piece was chromed or polished, even the pulleys, oil pan, bell housing, etc. Plating was done by Custom Chrome Plating in Paramount, Calif., who Dan recommends for superb chrome work.

The exhaust system consists of tube headers which flow down to a collector unit that couples with a three-in pipe. This pipe contains staggered baffles perforated with holes and acts as the muffling system. Dan also ran tailpipes from the large side-pipes, and these carry the exhaust to the rear of the machine, keeping the tires cooler (since the exhaust no longer exits directly on the tire) and the noise level even lower and away from close proximity to the ears.

Cooling is provided by a stock Mustang radiator which mounts in the rear of the fiberglass body. Air is ducted through openings in the sides of the body, and is helped through the radiator's core by a 12-volt fan from an XKE Jaguar. Air going through the radiator is blown out, instead of being pulled in, just the opposite of what you'd find in any automobile.

The coolant is straight anti-freeze, and runs from the engine through a long piece of plated tubing to the radiator, where it returns via a similar route back to the engine. A ballast tank was built just to the front of the Mustang engine and handles any pressure surge that might occur.

An Ethno-Trike, Powered By Ford.

Normal temperature around town is about 185 to 190 degrees, while trips down the open road cool it somewhat down to 180. No heating problems have ever occurred in 7000 miles of driving, proving that the system works well.

A fiberglass body sets the machine off. Fenders were added to the rear to keep the dirt down (and those giant tires would throw a lot of dirt!), and 1960 Chevy taillights formed into the rear deck above the radiator screen are simple and blend well into the overall styling concept. The body attaches to the frame unit by brackets glassed directly to the structure, then bolted to the frame.

Just behind the black leather seat, stitched by Mario of Compton, is a 6-gal. gas tank that provides more than enough fuel for long trips, since the gas mileage usually ranges in the upper half of the 20-mpg bracket.

The little 289 doesn't have to work too hard to propel the 1472-lb. machine along at any speed. 80 mph can be reached in less than 7 sec. if you so desire, quick enough for anybody.

For his riding pleasure, Hernandez installed a J.C. Penny Mini Tape Deck which he mounted directly to the handlebars. The custom-made bars also act as a shock absorbing device for the tape deck, since they tend to flex and cushion the rough jolts. Speakers were installed to create a stereo effect; one mounts just to the rear of the rider's head on the gas tank hump, and the other is under the front of the seat.

Stewart-Warner gauges keep tabs on "what's happening" up front, and Japanese quartz iodine lamps light up the road ahead at night. The lamps are protected by Porsche screens.

As you can tell, Molly, a name well known to motorcycle racers, once again outdid himself with the spray gun and produced one heck of a fine paint job on the trike.

Other than body painting, chrome, and heavy machine work, everything was done by Hernandez himself, who has proved with this fine example that he is quite a craftsman and takes great pride in his work. His attention to detail is superb with no part left undone.

He estimates that he has put about 400 man hours into his trike, at a cost of approximately $2800. Actually, the true cost of the machine was $2700, but an outfit for his wife as sort of an appeasement raised the total somewhat. You married fellows know what we're saying, right?

Dan's present plans include selling the trike and starting a new project shortly, but meanwhile he continues with his mind blowing (for onlookers) trips down the road, gazing calmly through the custom amber windscreen, while listening to that J.C. Penny tape deck.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

DECEMBER 1971 By Joe Parkhurst -

Letters

LettersLetters

DECEMBER 1971 -

Departments

DepartmentsThe Service Dept

DECEMBER 1971 By Jody Nicholas -

Departments

DepartmentsThe Scene

DECEMBER 1971 By Ivan J. Wagar -

Features

FeaturesViewpoint: the Road Bike In Tomorrow's World

DECEMBER 1971 By Dan Hunt -

Competition

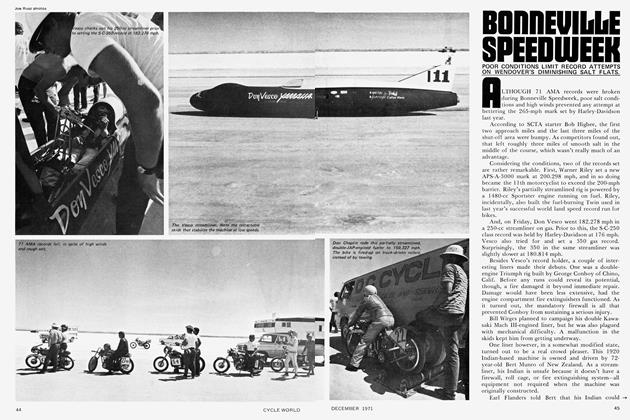

CompetitionBonneville Speedweek

DECEMBER 1971