THE SERVICE DEPARTMENT

JOHN DUNN

PRE-PURCHASE PREPS

I am buying a 750-cc Honda Four and I have four specific questions.

1. What can be done about the chain oiler getting oil all over the rear wheel and pipes? Can it be shut off altogether and the chain lubed manually?

2. Should the final gearing be lowered for two-up touring with saddlebags?

3. What weight oil would be best for fast long distances at 70to 90-degree temperatures?

4. Would you advise the use of an oil additive such as STP or any kind of an upper cylinder lube in the gas?

Robert Kummer Sheboygan, Wis.

The Honda Four chain could be lubricated in the normal fashion. However, if the present system appears to issue too much oil, it may be worth trying to reduce the quantity of oil being supplied by employing a smaller metering orifice.

Most Hondas seem a little over geared, particularly when a passenger is carried. I suggest you first try the machine with standard gearing. Then, if not satisfied, install a rear wheel sprocket with two more teeth or a gearbox sprocket with one less tooth.

Use the grade of oil recommended by the manufacturer for the operating temperature range you mentioned.

Oil additives such as STP are not advised in cases where the primary drive lubrication is integral with the engine lube system as clutch sticking problems are likely to occur. The use of an upper cylinder lubricant is also not recommended where a paper type air cleaner is employed. The quantity of oil which is blown back into the air cleaner impairs its efficiency.

CURRENT CRISIS

What are the differences among the three different generating systems in use on motorcycles today and what are the advantages of each? The three, to my knowledge, are d.c. generator, a.c. alternator with permanent magnet and a.c. alternator with excited magnet. Why do British hikes have a diode in their circuits?

Douglas Brent ling San Francisco, Calif.

Twenty years ago the majority of motorcycles and automobiles were equipped with d.c. (direct current) generating systems. Today most of them employ a.c. (alternating current) systems. Direct current flows in one direction only. Alternating current first flows in one direction and then in the opposite direction. However, a battery can store only d.c., so a.c. must be converted into d.c. current, and made to flow in one direction only in order to be stored. Simply, you cannot charge a battery directly from an a.c. generator; the current has to be rectified to d.c. first. Some machines employ a direct lighting system. Here, no battery is employed and a.c. current is used for both ignition and lighting purposes. There are two or more coils in the a.c. generator. With the main switch turned to the “on” or “ignition” position, only one generator coil is brought into use, supplying sufficient current for ignition purposes only. When the switch is turned to the “lighting” position, another coil is brought into play to meet the additional demands of the lighting system. It is therefore necessary for the generator output to be just sufficient to meet all the electrical current requirements. Otherwise, if the output were too great, current would become excessive and the lightbulbs would burn out. All magnetos produce a.c. current.

Most motorcycle a.c. generating systems (alternators) employ the permanent magnet principle where there is no control of the field current. Two things influence the output of a generator. With a fixed field current, the output increases with rotor speed. With a fixed rotor speed the output rises as the field current is increased. In the majority of automotive a.c. generating systems the generator output is controlled by a voltage regulator in circuit with the field coils. It controls the strength of the field current. The permanent magnet alternator does not have a sophisticated voltage regulation system; it relies on finely balanced output and load requirements. It has no brushes or components that will wear out other than its bearings. It will operate in oil and requires no maintenance.

The d.c. generator has brushes that run on a segmented commutator. The brushes and commutator become worn during normal operation and therefore periodic maintenance is essential. Performance of the unit is adversely affected by the presence of oil, water and

dirt. The d.c. system has a voltage regulation system similar to the one previously mentioned.

The Zener diode employed on some makes of British motorcycles is the main component employed in a voltage regulating system for permanent magnet a.c. generating systems. It provides automatic control of the charging current.

To put it simply, the Zener diode is an electrical switch which operates only when the battery voltage reaches a predetermined high, grounding the excess current through a well cooled heat sink. It has the advantage of insuring that the battery does not become over charged if generator output is excessively high.

IT'S ALL WORK

/ have been riding motorcycles for five years and have been trying to get as much technical information together as possible. There are several things that 1 am confused about. What is the difference between torque and bhp? They both appear to be a measure of engine output or power. What is their relationship, as I have noticed that both are given in the manufacturers’ specifications, although at different engine speeds.

F.R. Brown Santa Barbara, Calif.

Torque and bhp are directly related. Torque is the turning effort at the engine crankshaft. It is at its maximum when the pressure on the piston is at its highest. Bhp is a measure of work done in a given time.

The torque that an engine is capable of developing changes with engine speed. An engine’s highest efficiency is attained at the same speed where maximum torque occurs. This is usually at approximately midpoint in the engine speed range, when volumetric efficiency (there is sufficient time for the cylinder to fill with air and fuel at this moderate speed) is at its highest point. Below and above this speed the torque will fall off, mainly because of the engine’s inability to take in a full volume of air. This is more pronounced as the engine speed rises due to the lack of time available for the cylinder to fill. Therefore as the engine speed increases and the volumetric efficiency drops, the torque will be lower because of the decreasing pressure on the piston.

The bhp curve of an engine is completely different from that of torque curve. Bhp starts low at low engine speed and gradually increases as the engine speed rises up to a point where volumetric efficiency is falling off alarmingly and the mechanical losses have attained a high level. This is the point at which maximum bhp occurs.

View Full Issue

View Full Issue

More From This Issue

-

Departments

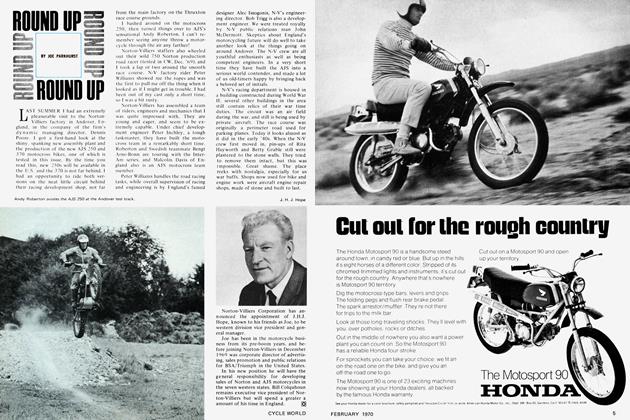

DepartmentsRound Up

February 1970 By Joe Parkhurst -

Letters

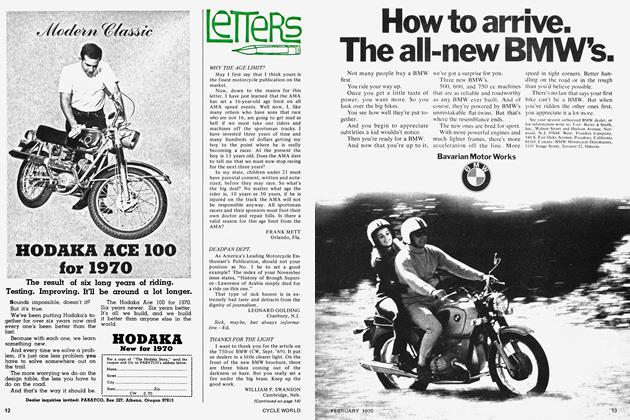

LettersLetters

February 1970 -

Departments

DepartmentsThe Scene

February 1970 -

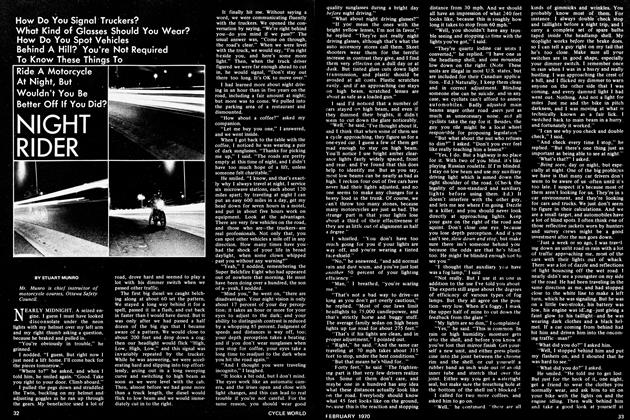

Features

FeaturesNight Rider

February 1970 By Stuart Munro -

Features

FeaturesHow To Teach Your Girl To Ride

February 1970 By David C. Hon -

Special Color Feature

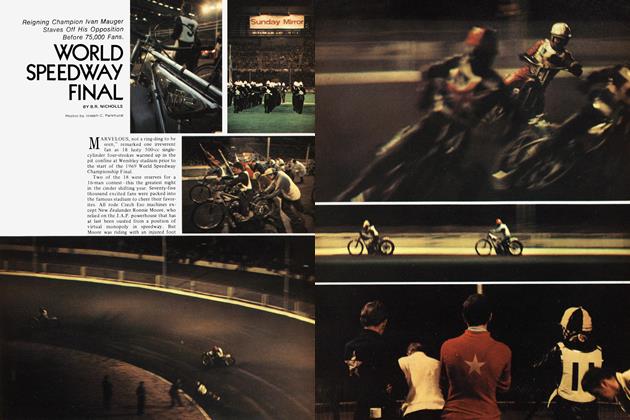

Special Color FeatureWorld Speedway Final

February 1970 By B.R. Nicholls