THE SERVICE DEPARTMENT

JOHN DUNN

350 KITS

I have a 1965 Honda 250cc Scrambler. I would like to change over to a 305 Super Hawk and would also like to install a 350cc kit. What changes would have to be made?

D. H. Taylor Indianapolis, Indiana

A 350cc conversion kit can be obtained from Webco Inc. for increasing the displacement of either the 250cc or 350cc twin cylinder Hondas. The kit is manufactured by Forgedtrue and consists of the following items: cylinder liners, special pistons. complete with "Dykes" type piston rings, a set of special valve springs, including bottom retainers, also a 350cc cylinder head gasket. It is also possible to obtain a modified cylinder barrel with 350cc sleeves already installed for those who are unable to carry out the necessary machine work themselves. Although the conversion can be applied to either the 250cc or 305cc cylinder barrel, we do consider that the 305cc barrel does present the best proportion due to increased cylinder wall thickness, allowing better liner support and greater heat transfer characteristics. When the 250cc barrel is bored to accept the larger diameter sleeve, the tool quite often breaks through the original cylinder wall. It is also necessary on the 250cc engine to enlarge the crankcase mouth sufficiently to allow the larger diameter sleeve spigot of the 350cc barrel to enter. This is not necessary on the 305cc engine. The carburetors should be rejetted to suit the increased displacement.

A booklet containing full details and instructions is supplied by Webco Inc. with each kit.

SLOW GAS BALLS

1 heard that Scrambler pipes like the ones Honda uses cut down on engine horsepower. Is this true? A friend told me that from pushing the exhaust gas uphill, it cuts down on the engine's horsepower.

Bob DeVore Lakewood, California

Providing there is no restriction to gas flow, caused by acute bends or reductions in the pipe cross sectional area, it is not important whether the exhaust pipe is of the high level variety (scrambler type) or low level (typical TT type). If both types were the same length and diameter, the effect on engine performance would be the same. Generally speaking, a long pipe will provide maximum effect at low engine speed and a short pipe at high engine speed. Your friend's remark about a reduction in horsepower being attributed to the gasses being pushed uphill, is without foundation. This condition will have no effect on engine performance.

We have many letters referring to the correct proportions of an exhaust system for many individual machines. There are many factors that influence the final choice of an exhaust pipe length, and without knowing exact details of actual valve timing and the engine speed where maximum effect is desired, it is impossible to suggest a tuned length.

Those interested in learning more about exhaust pipe design and the related conditions influencing good volumetric and thermal efficiency should obtain the CYCLE WORLD Technical Manual.

ECONOMY

Why do big English twins have alloy heads and cases, but cast iron barrels, whereas Hondas, etc., have all alloy engines? The only answer which has been suggested to me is that heat transfer from iron sleeves to alloy barrels is not very efficient, but the smaller bikes have sufficient fin area/displacement to get away with it. What about it?

Cecil Harper Portland, Oregon

We can only assume why the manufacturers of the majority of the big English twins employ a cast iron cylinder barrel; the reason is almost certainly not related to any differences in the thermal conductivity and heat transfer characteristics of the two systems. In fact a well designed aluminum cylinder will always provide the best condition in this respect; even with its slight resistance to heat transfer between liner and barrel, it is still more efficient, due to the high thermal conductivity of aluminum.

The iron cylinder, under normal conditions, provides adequate cooling, it is less expensive to produce, and with the methods used to bolt it to the crankcase, (in the case of the British twins mentioned) provides greater strength to material thickness, than would an alloy cylinder of similar proportions. Most alloy cylinders have retaining bolts passing right through the cylinder and head and do not rely on a flange type mounting, which is the case on most engines employing an iron cylinder.

An alloy cylinder is the best all-round theoretical proposition and does have a substantial weight advantage.

SEIZURES

At the time of this writing, my local Honda dealer is still unable to find the malfunction in my CB 160.

The problem first developed after the bike was about one month (1,000 mi.) old. When the bike had been ridden for about one to two hours, the engine seemed to be seizing. The sensation felt was that the pistons were being slowed down, due to some fault. This usually happened in the speed range of about 60, and usually under load (i.e., passenger or baggage). When this "seizing" begins, the bike immediately slows down to about 40; applying more throttle causes the bike to slow down even more. After running at this reduced speed for several minutes, the throttle can be opened and the bike will accelerate until the same sensation develops. Downshifting at this speed to third seems to overcome this malady. As soon as top speed is reached in third, however, and fourth gear is engaged, the engine immediately seems unwilling to perform.

(Continued on page 38)

This is the second time that the bike is in the shop for this reason. The first time, the cylinders were replaced. The dealer said that the liners had come loose of the cylinders, due to an incorrect fit.

Is it possible that the pistons are causing the damage to the cylinder sleeves? Another rider thought that 1 might be having valve trouble. I would greatly appreciate any information that you can give me about this problem. I have two friends who have last year's 160, and they seem to be having the same trouble, except at higher speeds (75-80).

William D. Harter New York, N.Y.

From the symptoms described, it is very likely that your CB 160 is suffering from a partial piston seizure. To my knowledge, this is not a common ailment with the CB 160 if the machine has been runin correctly and is in proper adjustment.

The sensation of seizing may also be caused by spark plug failure at high operation temperatures. If this is the case, it will be necessary to use a colder spark plug, particularly when the machine is driven hard. Honda indicates that either a NGK D-10H or D-12H be used under these conditions. An incorrect and overheated spark plug can cause severe engine damage, piston failure and seizure.

50 PLUS 65 = 59.3

I have a Honda 50 (C-100) and I want to put a Honda "65" piston in it. Can this be done without any alterations other than bigger jets in the carb? Also, will this help performance and top speed?

Jerry Luschen Lambertville, Michigan

It is possible to bore the Honda 50 cylinder barrel and install a Honda 65 piston. If this is done, it is necessary to use the 65 head gasket and it may be necessary to machine the head or piston crown to ensure adequate piston-to-head clearance. Using the 65 Honda 44mm diameter piston will increase the cylinder displacement to 59.3cc. Quite an appreciable gain in performance can be obtained. It will be necessary to use a larger jet in the existing carburetor, also possibly a colder spark plug, due to the increase in compression ratio.

LARGE TWO-STROKES

I have read in other motorcycle technical books that the two-stroke engine is a fine engine for lightweight bikes, but that it is not a good large displacement engine for a number of reasons involving power, volumetric efficiency, etc. If this is true, how do some foreign auto manufacturers, such as Saab and DKW, get away with using large displacement two-stroke engines successfully? Also, what is the usual combustion chamber shape on motorcycle racing engines and on regular production engines if there is a common design? I know that for auto engines, the hemispherical head is one of the most powerful because of its breathing advantages. Are any "hemis" used on bikes?

And just out of curiosity, when can you tell us more about the new Ducati 1260cc Apollo four? Is it on the market yet and when will you be able to road test it?

Mike Regan Minneapolis, Minnesota

It is partially correct to assume that the air cooled two-cycle engine system is more suited to engines employing a small cylinder displacement. The main disadvantages encountered with the large displacement cylinder are directly related to the effects of undue piston and cylinder barrel distortion, which invariably result in piston seizure. In the past, it was generally considered that a cylinder over 250cc was not practical. However, in recent years, due to advances in material technology and detailed attention to piston and cylinder barrel design, there has been a tendency to employ larger cylinder displacements successfully, particularly in motocross competition engines. There are now several very successful 360cc single cylinder motocross engines.

Cylinder distortion problems are not only confined to large displacement cylinders. There is a marked tendency toward water cooling on high output road racing two-strokes, which employ cylinders of only approximately 62cc displacement. It has been found necessary to employ water cooling even at the added disadvantage of a substantial increase in the total weight of the machine.

The automobile engines you refer to are water cooled and do not have cylinders of relatively large displacement, each individual cylinder being in the region of 250cc.

The majority of four-stroke motorcycle engines for many years have had hemispherical combustion chambers. On many road racing engines, in order to improve breathing at the extremely high operating speeds, there is an increasing tendency toward employing four valves per cylinder. These engines use what is known as a "pent-roof" combustion chamber.

It is most unlikely that the Ducati 1260cc Apollo four will ever be available . To our knowledge, this machine has never reached the final stages of development.

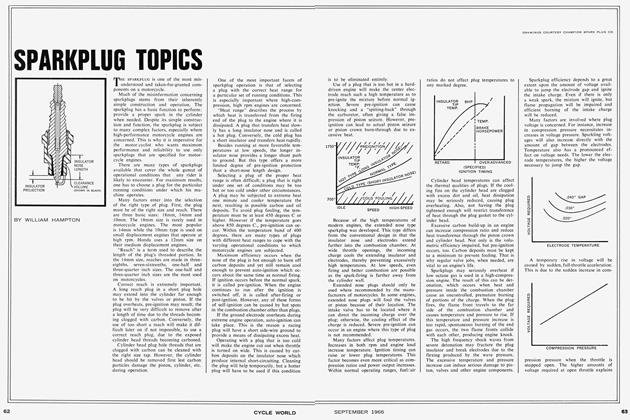

HOT POT

Recently 1 purchased a 1962 BMW R60. I hadn't had any experience with motorcycles before. I have been having troubles with it, but am unable to locate the cause. The right hand cylinder has been heatingj up. It heats up to the extent that the piston tries to seize the cylinder wall. It has the original Bing carburetor on it. Previously, the exhaust valve on the right head cracked about half way around the head where the valve stem connects. 1 had a valve machined, which remedied this problem. Presently, I have the right cylinder torn down. The piston has been so hot that the domed center has given way. The cylinder wall is scored a bit. 1 have examined all paris, but cannot find the cause.

(Continued on page 40)

Gene Smith Checotah, Oklahoma The problems being experienced with your 1962 R60 do not normally occur with this model, unless it has been severely abused and running in a critical condition for a considerable time. The melted piston crown and subsequent piston seizure is most likely closely connected with the exhaust valve failure. Insufficient valve tappet clearance or a badly sealing valve seat can cause extremely high piston crown temperatures at a point adjacent to the exhaust valve. This alone could have caused the piston crown failure.

Both the valve and piston failure may have resulted from prolonged running with the engine incorrectly tuned. A retarded ignition setting, weak carburetor mixture, or an incorrect grade of spark plug may have been responsible. An extremely lean carburetor mixture can be caused by a faulty float or an air leak between carburetor and valve.

I would recommend that the scored cylinder bore is checked by a qualified person, and if a rebore is necessary, have the left-hand cylinder bored also, both cylinders being fitted with new pistons of the same stage of oversize. Have both cylinder heads decarbonized, checked and then rebuilt.

After the engine has been reassembled, make sure that everything is adjusted to the correct specification as detailed in the manufacturer's instruction book.

TWO-STROKE RACER

1 am starting to prepare a Yamaha YL-l twin Jet 100 for road racing at circuits around the U.S., and since this is my first two-stroke, 1 hope you can help me on a few things.

1 want to increase the compression from the stock 7.1:1 to 11.6:1 with a set of heads from the J&R Equipment Company. These people offer two types of heads: trench type or hemi. Which of the two would be more desirable and what other modifications would 1 have to make with these ultra-high compression heads? I also plan to install competition expansion chambers. Also, would it help to install larger carbs and, if so, what type and size would work best?

I purchased a tachometer from my brother (he bought a Honda CR-93 racer in Tokyo) and was wondering how 1 would go about installing the tach, if it would be possible. I am buying the machine brand new. Should 1 put a thousand miles or so on the motor before making the changes or make the changes while still new?

1 would also appreciate any other "tips on speed" you may have.

George Black New Braunfels, Texas

The hemispherical - type combustion chamber would definitely be the best choice for your YL-l Yamaha. If a large increase in compression ratio is made, it will almost certainly be necessary to carry out other engine modifications to obtain an increase in horsepower and minimize the possibility of adverse operating conditions. The higher compression ratio will cause an increase in combustion chamber gas temperatures, which automatically results in higher residual exhaust gas pressures. It is essential that the combustion chamber pressure is lower than the rising pressure in the transfer ports when the latter opens. A higher pressure in the combustion chamber will result in reverse flow conditions in the transfer ports, which in turn will have an adverse effect on good cylinder filling and a subsequent reduction in horsepower, and an undesirably high engine operating temperature.

To obtain the desired balance of pressures between transfer port and combustion chamber, it is necessary to either increase the transfer port pressure or reduce the combustion chamber pressure at the time of transfer opening. This is possible by opening the exhaust port sooner, thus allowing a longer exhaust period. This unfortunately reduces the compression ratio slightly, due to the theoretically shorter working stroke. The compression ratio on a two-cycle engine is calculated from the theoretical swept volume. This is the cylinder volume, measured from the top of the exhaust port to the top of the stroke. With a large increase in compression ratio, it may be necessary to carry out both modifications to obtain the best results.

(Continued on page 42)

Carburetor size will be greatly influenced by the extent of other engine modifications. Your final choice will almost certainly be between 18mm and 22mm.

It is unlikely that the Honda CR93 tachometer will be suitable, due to a possible difference in drive gearbox ratios. The CR93 tachometer is suitable for a 3 to 1 drive gearbox ratio, being driven at half engine speed from the camshaft.

It will be well worthwhile running in your machine before carrying out the modifications to give you an indication of the mechanical condition and acquaint you with the handling characteristics and with the controls.

I would recommend that you buy the CYCLE WORLD Technical Manual and study the section dealing with racing expansion chambers, as these will give you the largest single gain.

CHROME BORES

I've had a question which has been bothering me for quite some time, so 1 decided to write to the most reliable source of information. How would chrome plating on pistons and cylinder walls affect engine performance?

Mark Beasley Carlinville, Illinois

It would not be practical to chromiumplate both the cylinder wall and piston skirt. Materials of similar molecular structure are not compatible when there is relative movement between the two contacting surfaces. Even under good lubrication conditions, seizure would occur.

Chromium plating the cylinder wall only is worth considering, though. I know of several instances where this process has been successfully applied, on BSA, Gold Star and Matchless machines used for motocross. Previously, when operating in dusty conditions, cylinder bore wear proved to be a problem, requiring frequent cylinder barrel changes. With the chromium plated bore it was possible to go through a complete season or longer with the same barrel.

Most engines with an iron bore now employ a chromium plated top piston ring for the same reason. However, if one decides to chromium plate the cylinder bore, it is essential that the chromium piston ring be replaced with a cast iron ring. If this is not done, cylinder bore damage would certainly take place.

As a point of interest, there are quite a few two-cycle engines, employing an alloy cylinder barrel, where the chrome is deposited directly on the aluminum bore.

STIFF OILER

The past year and a half 1 have been completely rebuilding a 1959 Triumph T110 (650cc). I still have a lot of work, time, and money to invest before being satisfied that 1 have done a complete job of face-lifting.

Still, one major problem remains. Where the generator bolts up to the back of the timing cover, I have a terrible problem with oil leakage. I can't tighten it up tighter, or 1 will strip out the end plate on the generator.

My local Triumph dealer can't tell me what to do, because he doesn't seem to be able to figure out a solution, either.

Also, how much is involved in repairing front shocks that are stiff? In other words, they don't shock.

Robert Lee Hoffpauer Richardson, Texas A leak at this point can be cured by fitting a new cork gasket. To install, slacken off the generator clamp, remove the domed nut on timing case, and slide generator out. Clean sealing faces, making sure there are no burrs or gouges. Then lightly smear grease on the new cork gasket before it is installed. It's not necessary to overtighten the timing case nut, only tighten enough to obtain sealing pressure at the joint. The generator is held in place mainly by the mounting strap tension.

You haven't given us much to go on regarding your fork problem. There could be too much oil in them, or incorrect viscosity. First drain the forks completely and refill with SAE 20, using 1/6 pint (lOOcc) in each leg. However, you also say you have been rebuilding the machine for a year and a half; the problem could very well be corrosion or rust on the stanchions, causing the bushes to seize, in which case the forks will have to be taken apart.

"POP CYCLE" SLIP

I recently purchased a 1953 HarleyDavidson 3 wheeler for use in my business. 1 have run into an acute problem. In my business 1 deliver popsicles, and my exhaust pipe runs directly under the storage bin. This tends to melt the popsicles at the bottom of the bin. 1 tried high scramble pipes, but the kids burned their hands on them. What can 1 do?

One more thing. 1 have recently become very interested in drag racing. I have encountered severe traction problems. Do you know anyone that makes slicks in my size? So far my best time has been 27.46 @ 52 mph (with a full load of popsicles). 1 imagine a set of slicks would really help my E.T. 1 would appreciate it very much if you would print my letter since I'm losing a lot of popsicles. Thank you.

Rongus Rogy Raytown, Missouri

We would suggest that you don't need slicks. The melting popsicles are probably dripping onto your back tires, causing a lot of slippage down the quarter. Perhaps if you tried a "dry run."

OIL QUERY

I have purchased a Honda 305 Super Hawk and have a few questions concerning its upkeep. Firstly, do I use a detergent or a non-detergent oil? Is it all right to use aircraft oils such as Aero-Shell ashless dispersant oil? Would a quartercan of STP with each oil change help?

Secondly, what is a good break-in procedure to follow? The shop mechanics don't even agree on this!

Thirdly, is there any way to keep the vibration from breaking taillights, chainguards, etc.? My friends tell me these things happen on the Hawk.

(Continued on page 48)

Fourthly, just how good is the Yetman space-frame? I have heard both good and bad about it, and writing to the company would, of course, only provide me with one point of view: that favorable to the frame. Will it hold up under road-use? Vibration? Will a Hawk equipped with this frame handle better at speed? (I don't intend to race.)

Lastly, is it possible to obtain a good four or five-speed close-ratio transmission? That is, one that doesn't play all the cute tricks the stock tranny does, while increasing speed potential. I have ridden Triumphs before and don't see why Honda transmissions can't be as good.

Dan Kuttner Austin, Texas

We have received many letters from readers asking what type of oil should be used in their machines.

First of all, judge mainly by the type and grade of oil recommended by the machine manufacturer. Remember, he has the reputation of his product at stake and will not recommend a brand or grade of oil that has not been found suitable by extensive research and test.

The majority of oils today contain a percentage of detergent additive. Detergent oils do have the advantage of preventing or controlling the degree of lacquer formation on pistons and valve stems. Also, they help prevent excessive sludge build-up in the crankshaft and oil drillways.

My limited experience with "ashless" type oils has not been sufficient to comment with any certainty on their overall effect. I did observe that this type of oil does not appear to deteriorate as readily under extreme temperature conditions, and when drained, still appeared to retain its original condition.

It is my personal opinion that STP, when used as an additive, does have some beneficial effects when extreme engine operating conditions are encountered and does prolong complete oil film breakdown when abnormally high oil temperature and unit loadings prevail.

The most important factor concerning lubrication is the necessity for frequent oil changes. The value of frequent oil changes cannot be overstressed, and is of great importance during break-in period.

As you say, there are many schools of thought on the best or correct break-in procedure. The break-in period is critical and does have a marked influence on the life potential of the machine. During the first 200 miles it is essential that the engine is allowed to run freely, without undue load. In the case of your machine, do not exceed 4,000 rpm; also, do not allow the machine to slog (lug), but let it rev freely in each gear up to 4,000 rpm.

Make full use of the gearbox and change down whenever the engine starts to work hard. This also helps to break-in the gearbox and change mechanism. After the first 200 miles have been covered, gradually increase engine speeds proportional to the increased mileage covered. However, do not subject the engine to undue loads. This procedure should be continued until 1,000 miles have been covered. By this time maximum rpm can be employed briefly, but do not hold maximum too long. It can take as long as 2,500 to 3,000 miles to run-in an engine satisfactorily. During this period it is also most important that the machine is properly maintained, as advised by the maintenance schedule in riders' handbook.

It is true that taillight bulb filament breakage was a problem on earlier models. This problem has now been overcome by fitting a conventional bulb employing the "loop" type filament.

Sorry we do not have any direct experience with the Yetman space frame and cannot therefore comment on its virtues or vices.

IT'S A GRINDER

Two months ago 1 purchased a new Honda S-90. When 1 pull or engage the clutch and shift gears, there is an unnecessary grinding that I cannot identify, as none of the other Honda cycles have this grinding noise.

RICHARD E. CHAPPELL Cordell, Oklahoma 73632

It would appear that the trouble is being caused by "clutch drag." Make sure the clutch cable and clutch actuating mechanism are correctly adjusted to allow full disengagement. If the trouble still persists, it will be necessary to dismantle ihe clutch to check its mechanical condition, also that the plates are not distorted or binding on their splines or grooves.