THE SERVICE DEPARTMENT

JOHN DUNN

TANK CLEANUP

I’m in the process of cleaning up my ’66 Triumph and would like to do away with the oil tank. I would like to know the pros and cons on having my fuel tank split and using one-third for oil and two-thirds for gasoline.

Richard Boore Covina, Calif.

Containing the oil tank within the fuel tank is not without problems. The main disadvantage is transfer of a considerable amount of heat from the hot oil to the fuel. At normal operating temperatures, the oil tank will be 250F. Also, if the oil compartment were at the rear of the tank, this could prove very uncomfortable for the rider. Just try holding your hand on the side of the oil tank after a good hard run. If the oil tank is contained within the fuel tank, it will be necessary to isolate or insulate the compartments. The most logical place to locate the oil compartment would be at the front. If the fuel tank is of the pannier type (to accommodate the top frame tube), the tank virtually will have two compartments.

With this sort of arrangement it will be easier to accommodate a separate oil compartment. One whole side of the fuel tank could be isolated for oil. If this provided too great a capacity for oil, only the front half of one side could be used. However, it would then be necessary to insulate between the oil and fuel compartments.

To have modification of this type carried out properly would be fairly expensive. For first-class custom fabrication work of this type, I would highly recommend Bill Eaton Enterprizes, 24239 Friar St., Woodland Hills, Calif.

HEADACHE

/ am owner of a 1967 CB-77 Super Hawk equipped with a roller tappet cam kit supplied by Harmon and Collins, and a Webco 350 kit. After installing the 350 kit, an oil leak developed between the cast iron insert into which the spark plug is threaded and the aluminum head itself on both cylinders. What is the cause of this and the cure? Would you please comment on the feasibility of installing the new constant velocity Keihin carburetors found on the new 350 Honda on my machine.

Wardner E. Randolph Tewksbury, Mass.

This is quite a common problem on both the 250and 305-cc Honda Twins, even when they have not been modified with a 350-cc conversion kit. The cylinder head is manufactured with an integral steel skull that forms the combustion chamber, provides a good material for the valve seats, and provides a durable spark plug thread. The only place that the skull comes to the external surface is at the spark plug boss. Unfortunately, because of the difficulty in performing this manufacturing technique, oil leaks from the bottom of the cam box and finds its way out to where the steel and aluminum merge at the spark plug boss. I have heard of new heads having this fault, so it could be a waste of money to purchase a new cylinder head. Sometimes the fault can be cured by removal, disassembly and thorough cleaning of the head, then coating the inside of the cam box with a special high temperature sealing compound.

However, another problem does arise when the big bore 350-cc kit is employed. The larger cylinder bore exposes the joint between the steel skull and the aluminum head at the head face. This joint normally is covered by the head gasket on the standard 250and 305-cc models. Because of the high temperatures incurred during combustion, it has been known for this joint to open up, causing the aluminum head to be badly burned at this point. This may also cause leakage at the spark plug boss, the result of leakage of cylinder pressure at the joint. A head that has deteriorated at the joint on the head face could be reclaimed by machining the head face to accept a pressed in steel ring, thereby bridging the joint and moving the new joint to a point that is covered by the head gasket.

The constant velocity carburetors from the new 305-cc Honda can be adapted to fit on your engine and should perform very well. However, it is important that the CV carburetors are mounted in a horizontal plane and are not inclined. It is also necessary to rubber mount them to insure proper operation.

FLOW BENCH

Can you give me any information on how to build a flow bench for cylinder heads?

J. Merritt Battle Creek, Mich.

The cost of building a flow bench can vary considerably. A relatively inexpensive unit can be built if you are able and prepared to improvise. To achieve the latter successfully will require some basic knowledge of air flow, manometers, pumps and pressure measuring devices. I could not, within the medium of this column, even start to instruct you fully in these things. However, if you are conversant, I would suggest you proceed in the following manner.

(Continued on page 24)

Continued from page 22

First, it is best to pull air through the port and valve in the same direction as would be expected under normal engine operation. In the case of the intake system, air would be sucked through the intake into a dummy cylinder. To provide the suction it will be necessary to acquire a suitable air pump, and plumb the intake side (of the pump) to the bottom of the dummy cylinder. The pump size or capacity will depend on the quantity of air you wish to flow.

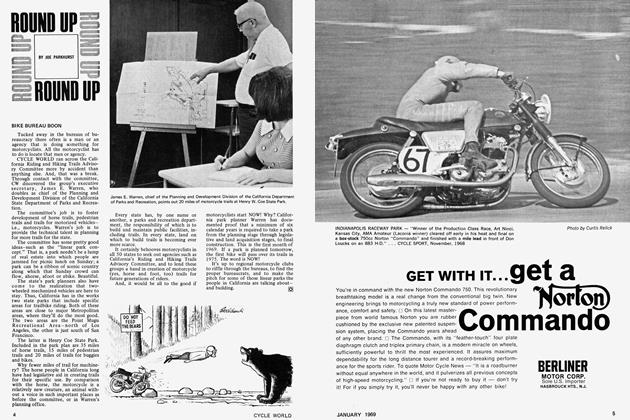

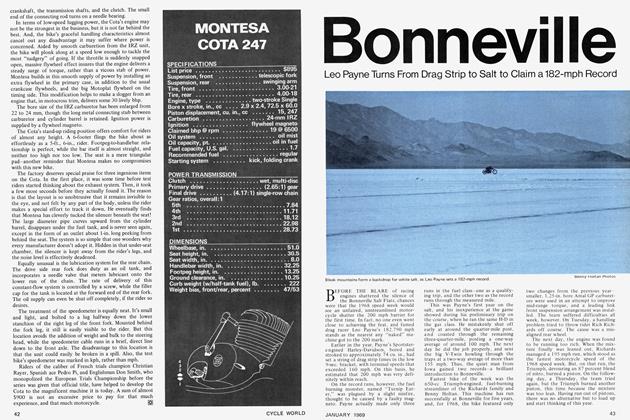

The next thing you will require is a water manometer, one side of which is open to atmosphere, and the other side of which is connected to the suction side of the intake valve (inside the dummy cylinder). With the valve fully open, you will require sufficient suction to obtain 10 in. of water on the manometer. This will indicate whether the pump has sufficient capacity. This first manometer is the “static pressure manometer.” If a globe or gate valve is installed between the dummy cylinder and the pump, it will then be possible to vary the static pressure. All conditions of flow should be measured at the same static pressure. If the maximum lift of the intake valve is 0.4 in., measure the flow at increments of 0.1 in. lift, always adjusting the static pressure by means of the globe valve to a given standard (8 in. of water). Whatever you are flowing, always use the same static pressure in order to obtain true comparison. To measure the amount of air that is flowing through the valve and port, it will be necessary to include a measuring device in the system. This will have to be in series with the intake valve and the vacuum control (globe valve), in other words, between the dummy cylinder and the globe valve. The simplest form of measuring device is an orifice (hole). When connected in series (in line), the amount of air that flows through the orifice will be the same, or very nearly the same, as that which flows through the intake valve. To measure the amount of air that is flowing through the orifice, and therefore the intake arrangement, it will be necessary to employ another manometer, preferably of the U-tube variety. Connect one side of the manometer just down-stream of the orifice, and the other side just upstream of the orifice. With air flowing through the orifice, there will be a pressure drop across the orifice which, in turn, will give a reading on the manometer. This reading represents the amount of air that is flowing through the intake arrangement. It can be read as inches of water and any change in the intake arrangement will alter this reading. It is not necessary to know the amount of air that is flowing, either in cfm (cubic feet per minute) or pounds per minute. The important factor is increase or decrease to evaluate the modifications you are making.

It will be necessary to experiment with the size of orifice used to obtain sufficient scale reading on the flow measuring manometer. The accompanying schematic shows the system described. If you wish to build a more sophisticated system, I would suggest you contact Meriam Instrument Co., 10920 Madison Ave., Cleveland, Ohio, for details of the firm’s laminar flow sensing unit and other finely calibrated instrumentation. [O]