Technical: the Flow Theory Way To Make A Sportster Go!

October 1 1970 Jody Nicholastechnical: THE FLOW THEORY WAY TO MAKE A SPORTSTER GO!

A Discussion Of The Principles Involved, And A Practical Demonstration.

JODY NICHOLAS

IN THE OLD DAYS, they called it porting and polishing. Now they call it flow theory. More has changed than just the name. Before an accurate method of testing the effects of port work was commercially available, much of this work actually reduced horsepower—exactly the opposite of the intended result. Grief and aggravation ran rampant among tuners and riders who believed and practiced the theory that a bigger, smoother port will flow more air, the result being greater horsepower and torque. Not necessarily so.

A normally aspirated engine is an air pump in that it must draw in and compress air; therefore, any restrictions to this process invariably lead to a loss of horsepower and torque. To get a better understanding of this phenomenon, we turned to Jerry Branch, of Branch Flowmetrics, for a graphic demonstration using a set of cylinder heads from a Harley-Davidson XLCH.

Jerry Branch has been involved with motorcycles since his teens, and has been preparing high-performance racing Harley-Davidsons almost as many years. His powerful engines have been winning races with clockwork-like regularity, and at one time or another riders such as Joe Leonard, Bart Markel, Dick Hammer, George Roeder, Mert Lawwill and Mark Brelsford have ridden Branch-tuned machines.

Jerry worked closely with the Harley-Davidson factory for a number of years in developing the 750-cc KR side-valve Twin to its high degree of sophistication. Probably no other side-valve engine in the world has put out as much horsepower-per-cubic-inch displacement. But the KR has been superseded by the overhead valve XR-750, and much of the developmental work must be credited to Jerry Branch. He is currently working closely with Harley-Davidson's racing chief, Dick O'Brien, to get the XRs up to the same level of performance and reliability.

Approaching the problems scientifically, Jerry has set up shop on the second floor of the Wixom Bros, fiberglass and fairing works in Long Beach. Here, Jerry works in his grinding room and at his flow bench to improve the breathing characteristics of motorcycle cylinder heads. He also does experimental work for Meyer-Drake Engineering, builders of the famous Offenhauser racing engines.

Presently, Jerry is involved in flow testing and modifying cylinder heads and carburetors for Harley-Davidson machines. He later hopes to expand his operation enough to get set up to do other machines, but right now his contract with the Harley-Davidson factory keeps him pretty busy. Few people know that the new XR-750 Harleys have Branch-flowed heads, and a great number of the 150-mph fuel-burning Harley-based dragsters are running them as well. Despite his heavy workload, Jerry took the time for an interview and two separate sessions at Lions Drag Strip in Long Beach to explain and prove the merits of his flow theory and his modification improvements.

Jerry's flow bench room is impressive by any standards. Housed in the work bench are the air supply (a McCulloch impeller-type supercharger driven by an electric motor), the intake for the laminar flow unit, and the flow unit itself, which is used to measure the air flow. Made of very thin, precisely-metered flat sections of metal in a tube-shaped device, the laminar flow unit is a precision instrument which requires cleanliness in order to function properly. Jerry cleans and tests all equipment each day to insure uniformity in his work, and the Miriam Instrument Co. components are all of laboratory quality. Regardless of the ambient air temperature or barometric pressure, work can go on as usual, as the readings obtained are all converted to a standard temperature and pressure: 70 degrees Fahrenheit and 29.92 in. of mercury. All flow tests are made using 12 in. of water on the vacuum gauge, which is the generally accepted standard for such work.

To show us how his apparatus works, and to have some material to use on our test bike, Jerry took a set of standard Harley-Davidson Sportster cylinder heads, measured the air flow at valve openings from 0.025 in. to 0.450 in., and corrected his findings to the "standard" temperature and pressure (see chart). He then ported and polished the heads, installed oversized valves and heavy-duty valve springs and again flowed the heads. Increases at all valve lifts were impressive, as can be seen in the accompanying charts. A number of other components were also flow-tested and the readings recorded. As an example, the chart indicates that an XLCH Harley-Davidson manifold originally flowed 165.78 cubic feet of air per minute (cfm) at 12 in. of water. After reshaping and enlarging the same manifold, the flow reading jumped to 192.95 cfm at 12 in. of water—a sizeable increase.

Following are the questions we had for Jerry on his theory and methods of modification.

CIA/: What factors affect the flow of air from the mouth of the carburetor into the combustion chamber?

Branch: We have to begin where the air is taken into the system, which is the carburetor entry. This pipe, which is the entry into the laminar flow unit, is a prime example of what I'm talking about. It's merely a piece of pipe. At 12 in. of water, it will flow 189 cfm of air. Now, lets put a bell-shaped entry on it. You'll notice that the inside diameter of this radiused piece of tubing is slightly smaller inside than the pipe is, but we get a reading of 245 cfm with it. The reason is that the radius directs the incoming air towards the edges of the pipe without the turbulence you find when the end of the pipe is cut off straight.

CIA/: How much variance do you find between standard Harley-Davidson Sportster heads when they come from the factory?

Branch: Quite a bit, really. Even though casting differences are slight to the naked eye, flow characteristics vary greatly. We've noticed that valve seat locations vary as much as 1/16 in., up or down, in the same batch of castings. That's one reason why two seemingly identical machines run so much differently.

CIA/: When you begin porting a head, are you interested in getting the ports as large as possible to get more flow?

Branch: No, in fact the inverse is more often true. Port volume must be kept as small as possible, consistent with keeping the flow high. High volume doesn't necessarily mean you'll get high velocity, which is a function of port size and shape. With today's high-rpm engines, velocity is very important. On the XR-750 Harley, at 8000 rpm only 1/3000 of a second is available to effectively fill the cylinder. If the flow process isn't aided by high velocity, insufficient filling is the result. So, we're searching for the highest flow combined with the highest velocity, and each is a compromise on the other. We have .found that smaller port sizes are a boon to low speed running too, and help make the engine much more flexible throughout the rpm range.

CIA/: We've heard that polishing the ports helps the flow, but reduces the atomization of the fuel/air mixture.

Branch: Polishing the ports does improve the flow somewhat, but by using my flow probe, I find that the flow right at the edge of the port is much, much slower than it is out toward the center of the port, at any point from the port's entrance right up to the valve. Besides, most of the atomization occurs during the fuel/air charge's entry past the valve and on the compression stroke. By using the flow probe, I can locate the areas where flow is poor and do something about it, whether it need be removing metal or filling in. On the racing Harley heads, when we were doing the initial development work, I checked all areas of the port at 0.010 in. valve lift increments with the probe and pretty well found where the design needed improvement.

FLOW THEORY

1969 SPORTSTER HEAD FLOW TEST FOR CYCLE WORLD 6-4-70

The XR-750 heads are capable of flowing enough air for a power output of 140 bhp, so obviously there are other design limitations which prevent the engine from developing that much horsepower.

CIA/: You mean like the shape of the combustion chamber?

Branch: Yes, and other factors, of course. I'm primarily involved with the cylinder heads, so I'll limit my discussion to the areas affected by them. In an SAE report, Honda published their findings on the tests of eight different combustion chamber shapes and found that the most efficient was a modified hemispherical chamber, that is, a chamber which is less than a true hemi. It permitted good valve and quench area. They found that the best quench was obtained with a side-valve engine: the KR Harleys are a prime example of this. Fuel burning is most complete. Most designers a few years ago relied on the true hemispherical chamber because it allowed large valve sizes in relation to cylinder bore size, but porting wasn't worked out well enough. The true hemi design requires the use of a high-dome piston to get the required compression ratiq, but this high dome partially masks the incoming charge of fuel and air, making it necessary to have a radical camshaft design which opens the inlet valve early to get the required amount into the combustion chamber. I mean, it's silly to open the inlet valve at 80 degrees btc to allow a full charge to enter when, with a smaller piston dome with less compression, you could open the valve at, say, 60 degrees btc. Of course, high compression aids power output-so there you are, between a rock and a hard spot. And, if a really high-domed piston is used, it is difficult to get good quench without detonation.

CIA/: What are your feelings about spark plug location in the head?

Branch: The best indication of an engine's combustion efficiency is where the timing is set at full advance. The closer you can fire the spark plug to tdc, the more efficient the engine is. It was found in tests that maximum gas pressure rise is about 1 7 degrees ate. These tests were made by Ford Motor Co. in conjunction with development of their dohe racing engines. They use one spark plug per cylinder in the middle of the head. The low-type chamber with a central plug is the coming thing. It doesn't restrict valve diameter nearly as much as a hemi and the quench area is good. There are no shrouded areas to block the gas flow, and a basically flat-topped piston can be used to get the required compression ratio. Obviously, a piston without a dome can be made much lighter than one with a high dome, which increases rpm and horsepower. Good flow can be obtained with smaller, lighter valves, and consequently smaller port sizes.

A good example of this is what Shelby has been doing with the small (302 cid) Ford engines for the Can-Am series. By

FLOW THEORY

cutting the port size and valve size down, they are getting the engines to put out more horsepower, and they have an engine with a much broader torque curve.

CW: But a small diameter, straight port isn't necessarily the answer to all the problems, is it?

Branch: No, it isn't. Because of design limitations, such as the type of engine and where it is located with respect to everything else on the motorcycle, compromises have to be made. For example, I made up a curved piece of tubing lined with clay and ran a perfectly round steel ball through it. The air had to change direction 90 degrees. By using my probe, I found that the perfectly round tube wouldn't flow nearly as much air at a high velocity as after I had cut some clay away and widened the tube's cross-section in the area of the bend. Of course, you can only find such things out by experimenting with different bends and shapes, and testing their effectiveness with the aid of the pressure-sensitive probe I use.

Cl/V: Fine, but what about the exhaust port? Is it as critical as the inlet port, or do you bother modifying it at all?

Branch: Oh yes, the exhaust port is almost as critical as the inlet, but it is different for a number of reasons. Most high performance engines have an exhaust valve which is roughly 70 percent of the size of the inlet valve. This is because exhaust gasses behave much differently than an unburned inlet charge, and you have the piston pushing the exhaust gasses out. I flow the exhaust ports on all the heads I modify and furnish the owner with a flow sheet. I also flow-test the exhaust ports by drawing air out of the port as the engine would run, not backwards like some people do. It's easy to do by making another adaptor for my flow unit's intake, and it's well worthwhile.

CW: This is all very interesting, Jerry, but we think it would be more meaningful to our readers if we could find a standard Sportster, run acceleration and top speed tests on it, then change to your flowed and ported heads, and run it again for comparison. By the way, what sort of horsepower increase are we talking about? Branch: The factory has run my heads on their dynomometer and picked up between five and seven horsepower. This is with the modified heads, enlarged and flowed intake manifold, and a slightly modified Tillotson carburetor with a tapered-bore inlet using the CY-CAL Products ram backing-plate and cone. This allows the rider to fit an aircleaner. I'll see if I can find us a motorcycle to test!

SPORTSTER TEST

The Sportster that Jerry found for us to test was a 1965 model belonging to Jim Hubbard of Long Beach. It was purchased new by Jim and had an odometer reading of just over 14,000 miles when we began our tests. It had had a recent tune-up by Harley-Davidson of Long Beach and was running well.

Our first series of three runs netted a best time of 14.25 sec. for the standing quarter-mile, with a terminal speed of 95.74 mph. Top speed was 106.63 mph—quite amazing for a five-year-old machine that was completely standard.

With the help of Dean Wixom of Wixom Bros. Co., we began changing the cylinder heads before the engine had cooled down. Within 45 minutes, we had completed the change and, after a couple of runs to get the jetting right, we began our second series of tests. Just how much good would these "trick" cylinder heads and the modified inlet manifold and carburetor do?

The best of our three runs netted a 13.48 sec. quarter, a terminal speed of 100.44 mph, and a top speed of 111.38 mph! Quite a significant increase.

Jerry advised us that the best cams for this machine are the Harley-Davidson "PB" cams, which are now standard equipment in the Sportsters and are superior to the "P" cams that our test bike had in it. So we got Jerry to install a set of "PB" cams and bring a set of open racing exhaust pipes and a smaller countershaft sprocket with him for the re-test.

THE RE-TEST

Three weeks later we were back at Lions Drag Strip. With a 19-tooth countershaft sprocket (one less tooth than standard) and the more recent "PB" cams, our best run was an amazing 12.79 sec. with a terminal speed of 106.63 mph, using the open pipes. With the mufflers in place, these figures changed only slightly and we got readings of 13.20 sec. and 101.01 mph. Top speed wasn't recorded because of the lower gearing.

In all fairness to the first test, we re-installed the 20-tooth countershaft sprocket and ran the tests again. With open pipes, our best standing quarter-mile was 12.85 sec., with a terminal speed of 104.52 mph. Top speed had increased to 119.84 mph. With the mufflers back in place, we turned a 13.24 sec. quarter and reached a terminal speed of 99.88. Top speed was 115.68 mph.

Needless to say, we were quite favorably impressed with the Sportster's performance, both before and after the modifications. Completely stock, our test machine turned in an elapsed time which was exactly the same as the 1969 XLCH we tested last year: 14.25 sec.

Each modification showed a significant decrease in elapsed time and an increase in the terminal speed for the standing quarter-mile, and the top speed increased as well. It must be pointed out here that our top speed runs were made through the clocks after a half-mile run from a standing start, and it is conceivable that the top speeds might have been even higher if the runs had been longer.

The tests were a tribute to Jerry Branch, his talent and his patience. They proved that he can back up his theories with action! [Ö]

View Full Issue

View Full Issue

More From This Issue

-

Department

DepartmentRound Up

October 1970 By Joe Parkhurst -

Letters

LettersLetters

October 1970 -

Departments

DepartmentsThe Scene

October 1970 By Ivan J. Wagar -

Features

FeaturesOldies But Goodies: Cycles & Sayings

October 1970 By Publilius Syrus -

Features

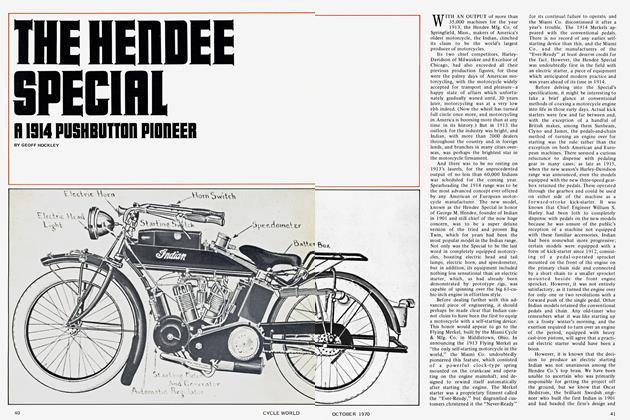

FeaturesThe Hendee Special

October 1970 By Geoff Hockley -

Competition

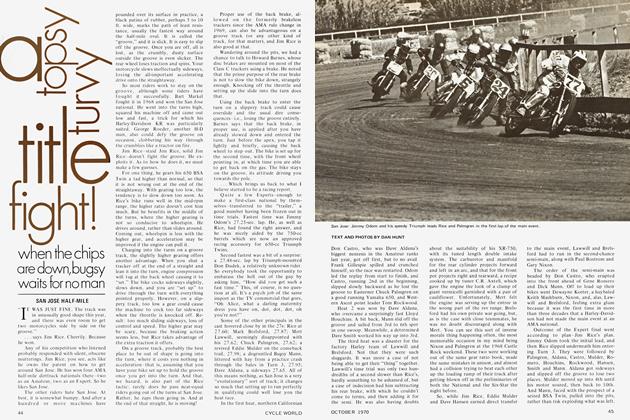

CompetitionA Topsy Turvy Title Fight!

October 1970 By San Jose Half-Mile