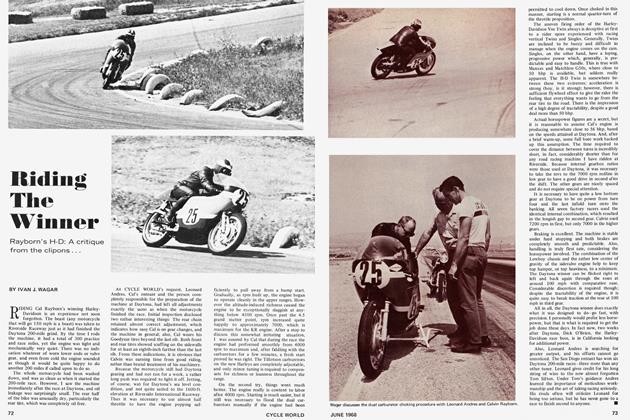

The Precision Machining Honda 450

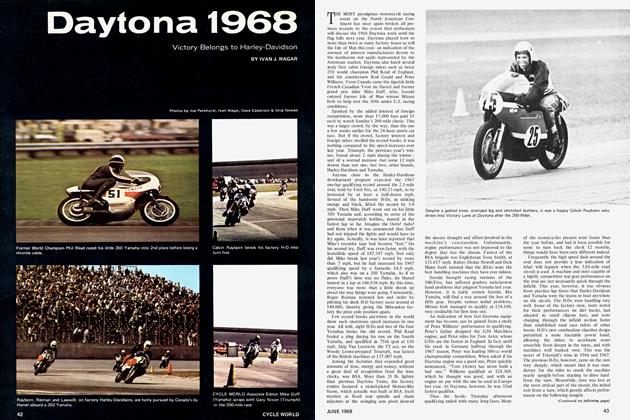

UNLIKE FACTORY backed counterparts in the Expert class, the winner of the 100-mile Amateur race at Daytona was a private entry. This is unusual, for even Amateur class entries in major meets such as Daytona frequently receive some factory assistance, if not outright backing.

The only assistance Honda gives Jerry Young and Jim Kibblewhite of Precision Machining, however, is producing its 450-cc dohc Twin on a mass scale, making it inexpensive enough for Jim and Jerry to buy.

“It’s quite advanced for a production engine,” says Jerry. “The changes we make are minimal and anyone can repeat them. The majority of standard engines are quite adequate.”

The main disadvantages of the 450 as a racing engine are heaviness and an infamously clumsy set of gearbox ratios that jump too wide between first and second, second and third, and too close between third and fourth.

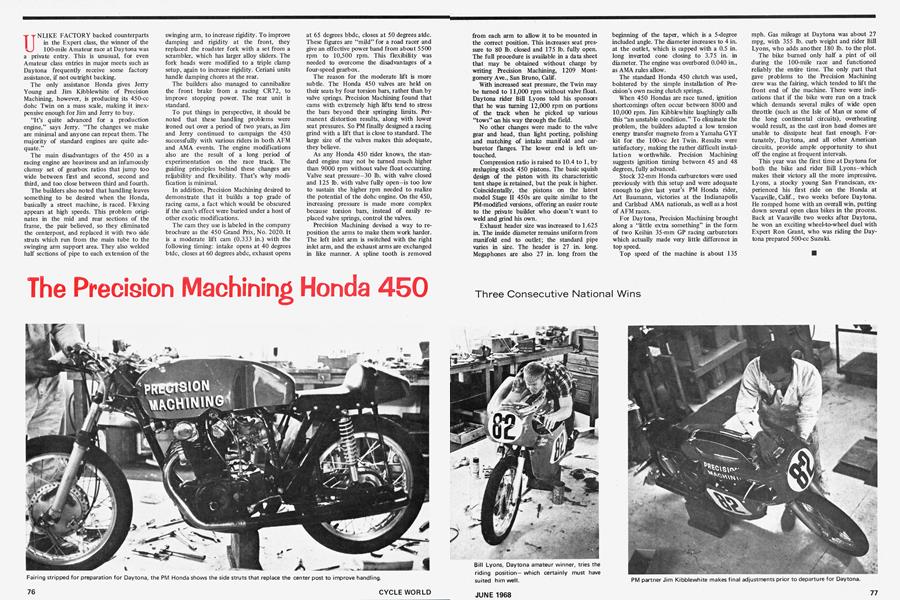

The builders also noted that handling leaves something to be desired when the Honda, basically a street machine, is raced. Flexing appears at high speeds. This problem originates in the mid and rear sections of the frame, the pair believed, so they eliminated the centerpost, and replaced it with two side struts which run from the main tube to the swinging arm support area. They also welded half sections of pipe to each extension of the swinging arm, to increase rigidity. To improve damping and rigidity at the front, they replaced the roadster fork with a set from a scrambler, which has larger alloy sliders. The fork heads were modified to a triple clamp setup, again to increase rigidity. Ceriani units handle damping chores at the rear.

The builders also managed to cannibalize the front brake from a racing CR72, to improve stopping power. The rear unit is standard.

To put things in perspective, it should be noted that these handling problems were ironed out over a period of two years, as Jim and Jerry continued to campaign the 450 successfully with various riders in both AFM and AMA events. The engine modifications also are the result of a long period of experimentation on the race track. The guiding principles behind these changes are reliability and flexibility. That’s why modification is minimal.

In addition, Precision Machining desired to demonstrate that it builds a top grade of racing cams, a fact which would be obscured if the cam’s effect were buried under a host of other exotic modifications.

The cam they use is labeled in the company brochure as the 450 Grand Prix, No. 2020. It is a moderate lift cam (0.333 in.) with the following timing: intake opens at 40 degrees btdc, closes at 60 degrees abdc, exhaust opens at 65 degrees bbdc, closes at 50 degrees atdc. These figures are “mild” for a road racer and give an effective power band from about 5500 rpm to 10,500 rpm. This flexibility was needed to overcome the disadvantages of a four-speed gearbox.

The reason for the moderate lift is more subtle. The Honda 450 valves are held on their seats by four torsion bars, rather than, by valve springs. Precision Machining found that cams with extremely high lifts tend to stress the bars beyond their springing limits. Permanent distortion results, along with lower seat pressures. So PM finally designed a racing grind with a lift that is close to standard. The large size of the valves makes this adequate, they believe.

As any Honda 450 rider knows, the standard engine may not be turned much higher than 9000 rpm without valve float occurring. Valve seat pressure-30 lb. with valve closed and 125 lb. with valve fully open-is too low to sustain the higher rpm needed to realize the potential of the dohc engine. On the 450, increasing pressure is made more complex because torsion bars, instead of easily replaced valve springs, control the valves.

Precision Machining devised a way to reposition the arms to make them work harder. The left inlet arm is switched with the right inlet arm, and the exhaust arms are exchanged in like manner. A spline tooth is removed from each arm to allow it to be mounted in the correct position. This increases seat pressure to 80 lb. closed and 175 lb. fully open. The full procedure is available in a data sheet that may be obtained without charge by writing Precision Machining, 1209 Montgomery Ave., San Bruno, Calif.

Three Consecutive National Wins

With increased seat pressure, the Twin may be turned to 11,000 rpm without valve float. Daytona rider Bill Lyons told his sponsors that he was turning 12,000 rpm on portions of the track when he picked up various “tows” cm his way through the field.

No other changes were made to the valve gear and head, than light porting, polishing and matching of intake manifold and carburetor flanges. The lower end is left untouched.

Compression ratio is raised to 10.4 to 1, by reshaping stock 450 pistons. The basic squish design of the piston with its characteristic tent shape is retained, but the peak is higher. Coincidentally, the pistons on the latest model Stage II 450s are quite similar to the PM-modified versions, offering an easier route to the private builder who doesn’t want to weld and grind his own.

Exhaust header size was increased to 1.625 in. The inside diameter remains uniform from manifold end to outlet; the standard pipe varies in size. The header is 27 in. long. Megaphones are also 27 in. long from the beginning of the taper, which is a 5-degree included angle. The diameter increases to 4 in. at the outlet, which is capped with a 0.5 in. long inverted cone closing to 3.75 in. in diameter. The engine was overbored 0.040 in., as AMA rules allow.

The standard Honda 450 clutch was used, bolstered by the simple installation of Precision’s own racing clutch springs.

When 450 Hondas are race tuned, ignition shortcomings often occur between 8000 and 10,000 rpm. Jim Kibblewhite laughingly calls this “an unstable condition.” To eliminate the problem, the builders adapted a low tension energy transfer magneto from a Yamaha GYT kit for the 100-cc Jet Twin. Results were satisfactory, making the rather difficult installation worthwhile. Precision Machining suggests ignition timing between 45 and 48 degrees, fully advanced.

Stock 32-mm Honda carburetors were used previously with this setup and were adequate enough to give last year’s PM Honda rider, Art Baumann, victories at the Indianapolis and Carlsbad AMA nationals, as well as a host of AFM races.

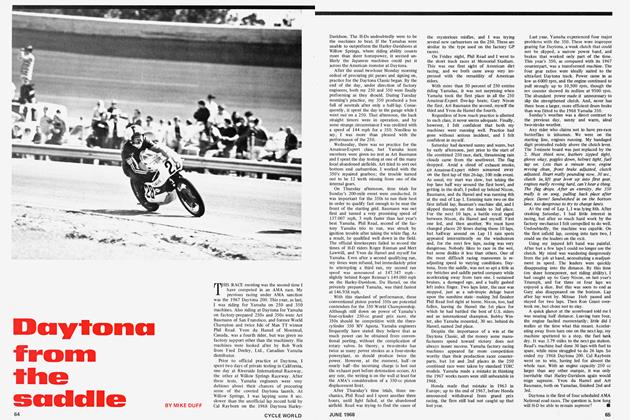

For Daytona, Precision Machining brought along a “little extra something” in the form of two Keihin 35-mm GP racing carburetors which actually made very little difference in top speed.

Top speed of the machine is about 135 mph. Gas mileage at Daytona was about 27 mpg, with 355 lb. curb weight and rider Bill Lyons, who adds another 180 lb. to the plot.

The bike burned only half a pint of oil during the 100-mile race and functioned reliably the entire time. The only part that gave problems to the Precision Machining crew was the fairing, which tended to lift the front end of the machine. There were indications that if the bike were run on a track which demands several miles of wide open throttle (such as the Isle of Man or some of the long continental circuits), overheating would result, as the cast iron head domes are unable to dissipate heat fast enough. Fortunately, Daytona, and all other American circuits, provide ample opportunity to shut off the engine at frequent intervals.

This year was the first time at Daytona for both the bike and rider Bill Lyons-which makes their victory all the more impressive. Lyons, a stocky young San Franciscan, experienced his first ride on the Honda at Vacaville, Calif., two weeks before Daytona. He romped home with an overall win, putting down several open class bikes in the process. Back at Vacaville two weeks after Daytona, he won an exciting wheel-to-wheel duel with Expert Ron Grant, who was riding the Daytona prepared 500-cc Suzuki.