THE SERVICE DEPARTMENT

JOHN DUNN

VALVE CHECK

I am 17, and own a Honda CL 160. When 1 bought it two years ago, I knew almost nothing about motorcycles. But after subscribing to CYCLE WORLD for a year, my knowledge has been vastly improved. The Honda owner's handbook tells me nothing about minor tuning jobs on the engine, such as adjusting the valves and carburetors. So every six months or so, I have to take the motorcycle to the shop, and fork out $5 to have these adjustments made. I asked the shop mechanic to show me how to do this work myself, but he refused. Most of my friends have the same problem. Can you tell me how to tune a CL 160 engine, particularly the valves and carburetors? Jim Fish Chesapeake, Va.

To adjust the valve clearance on your CL 160, first remove the alternator cover and align the "T" mark on the rotor with the corresponding mark on the stator housing. Both pistons will now be at tdc (top dead center). One will be on compression, with both valves closed and the other will be on valve overlap, with both valves partially open.

Adjust the valve clearance on the cylinder that is on compression. To do this, remove the valve inspection covers. Each rocker arm is provided with an adjusting screw that is locked in place by a lock nut. Insert a feeler blade (0.004 to 0.006 in. thick) between the end of the valve stem and the rocker adjusting screw. If the clearance is correct, the feeler blade will form a smooth, sliding fit. If adjustment is required, loosen the lock nut (turn counterclockwise to loosen) and turn the rocker adjusting screw until the correct clearance is obtained. Then, while holding the adjusting screw in position, tighten the lock nut.

When both valves have been set, turn the crank through 360 degrees so that the other cylinder is on compression. Repeat the adjusting process.

Insufficient clearance will prevent the valves from seating properly, and will cause the exhaust valve seats to burn. The result will be poor performance. Excessive valve clearance will cause valve clatter and probably will damage the valve train components (cam lobes, rocker arms and valve stems).

Tuning the carburetors means nothing more than keeping them clean and in proper adjustment. Always adjust the carburetors when the engine is warm. First adjust both throttle stop screws equally until the engine is running at between 1000 and 1200 rpm. Turn the pilot air adjusting screws until the engine speed just starts to increase, then re-adjust the throttle stops. Adjust both throttle cables so that they have approximately 0.040 in. of slack. Make sure that both throttles open together and that they reach full throttle simultaneously. Check this point when the engine is not running.

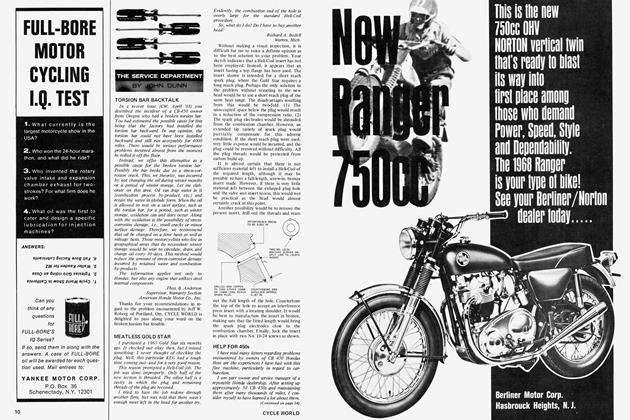

SOUND 750S

Several "informed" sources tell me that my 1963 Matchless 750, model Gl5 will develop bearing failure of some type. Is this true? The motorcycle has covered 30,000 miles, so I am having the valves ground and the cylinders bored out 0.040 in. I also am fitting new pistons and rings. Will this extra power ruin my bike?

Harry W. Cooper Dallas, Tex.

Several riders have complained to me about the durability of 750-cc Matchless and Norton engines. But I also have received as many letters praising the engine.

Most of the complaints have mentioned excessive vibration, combined in some instances with lower end failure. Vibration starts with an adverse balance condition in the crankshaft. The main and rod bearings have to cope with high loads, and vibration of the crank will impose extra loadings on them, resulting in possible failure.

(Continued on page 18)

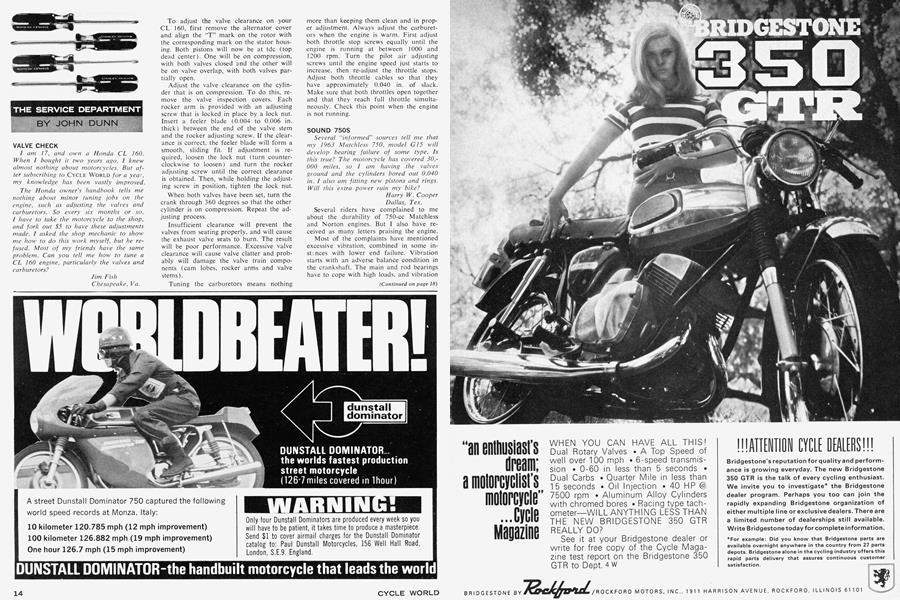

Basically, I believe these engines to be of sound design and, providing they are built within reasonable tolerances, are well cared for and sensibly ridden, they will give good performance and service.

If the lower half of your engine is in good condition, there is no reason why the overhaul should present any durability prob'ems. If you have doubts about the lower end, dismantle and inspect it.

After the rebore, it will be necessary to break the machine in again. About 500 miles with regular oil changes and maintenance should do the job.

TWINS VERSUS SINGLES

Are the 1968 BS A s advertised in the January 1968 CYCLE WORLD 100 percent made in England? What does BSA mean by the statement: "Specifications may vary between Eastern and Western models?" Our club members like the Western models, but if we order direct from England, will we receive a machine exactly as advertised in CYCLE WORLD?

The following question has bothered our club members for some time: what are the advantages and disadvantages of a single cylinder four-stroke compared to a fourstroke Twin?

David Molina

Dumaguete City, Philippines

BSA manufactures the models advertised specially to suit the American market. These models are not generally available in England, although there have been one or two exceptions to this rule. The English models are basically similar, but differ mainly in appearance, through such items as fenders, handlebars, tire sizes, color schemes and chrome plating. Differences in climate and geography between the east and west coasts also result in different demands in the U. S. Small changes in specifications are made to suit these demands.

The "Single vs. Twin" topic is an old controversy. The Single obviously is cheaper to produce, having fewer components. In the long run, it also is cheaper to maintain. Maximum power output is governed by limiting mechanical considerations that cause failure and malfunction at excessively high operating speeds. The Twin is capable of operating at much higher crank speeds, and providing its breathing ability is in keeping with the increase in crank speed, it will develop more maximum power than the Single.

If an engine of each type were designed to produce maximum power, the Twin could produce about 15 percent more horsepower than the Single. There are no balance advantages between a Single and a 360 degree parallel Twin, but the latter will run more smoothly by reason of the less intense and more frequent firing strokes. The Single delivers one big bang every 720 degrees, while the Twin delivers two smaller bangs at the same interval. Some riders prefer the thump of a good Single, while others like the purr of the multi-cylinder.

This is a matter of individual preference. Most arguments regarding the advantages of each type are more often than not prompted by these preferences. It is hard to decide which type of engine is superior, because good and bad examples of both types are available. To me, a good example of either is equally satisfying and thrilling.

(Continued on page 20)

BLUEPRINTING

I have read several articles in various magazines about "blueprinting" automobile engines. As I understand it, blueprinting is the process whereby all tolerances are checked and set to the specifications recommended by the manufacturer of that particular engine.

My question is, can specifications be obtained to blueprint a motorcycle engine ('66 Triumph 650)?

1 have heard this topic kicked around several times, but no one seems to have a clear idea of the process and its values.

William J. Abbott Alexandria, Virginia

"Blueprinting" is the accepted way to extract maximum power from a stock engine, while remaining inside the manufacturer's specified dimensions.

The process is carried out in NASCAR stock car racing engines and in the AHRA and NHRA stock and super stock drag engines.

The engines are usually bored to the maker's specified maximum, with combustion chambers, crank throws, port diameters, cam lifts, etc., all exactly matched on each cylinder. Engines also are built to truly close tolerances, much closer than in engines built for street use.

This process is used by most tuners of motorcycle engines, especially on production twins and the like.

THE BREAKS

1 own a CB 450 that now has been driven carefully for 5000 miles. I had had very good luck with the bike for about six months when recently a torsion bar broke in its middle at 4000 rpm. I had that particular assembly completely replaced along with valves, gaskets, etc. The motorcycle ran fine for about a week until I went to start it one morning, and the other torsion bar broke. Everything inside the engine appears to show very little wear, and the only thing I have been able to find out is that I seem to have a unique problem.

If you have any suggestions as to the causes and/or prevention of breaking torsion bars in a Honda 450, they would be greatly appreciated.

Jeff W. Roberg Portland, Ore.

The problem you have experienced with broken torsion bars in your Honda 450 is unusual. The only possible cause I can think of for the failures is that the factory slipped up and installed the wrong units. When the torsion bars are manufactured, they are preset (twisted). The right-hand intake and left-hand exhaust are preset to the right. This is indicated by a small arrow stamped on the end of the torsion bar. On the right-hand units, the arrow indicates a clockwise direction. The left-hand intake and righthand exhaust are preset to the left, and have an arrow indication an anti-clockwise direction. There is a slight possibility that the factory may have installed the wrong torsion bars, or that defective units slipped through inspection.

VINTAGE AJS

I recently acquired an AJS 500-cc Single, of an unknown vintage. Could you possibly tell what year and model it is from the engine serial number? The number on the block is 5318S139C.

I also would like to know if AJS or Matchless machines ever were produced with a dual spark plug head. I have such an item, and can't decide if the extra plug hole is a product of some previous owner's imagination or a genuine production accessory.

Thirdly, can the gears from an AMC transmission be interchanged with those of the Burman box? The cases look very similar. And, lastly, what does AJS stand for? Allen L. Newell APO San Francisco, Calif.

The first two numbers of the engine number indicate the year of manufacture. Yours is a 1953 machine. The model also is indicated in the engine number as being 18S. The 18 stands for 500-cc Single, and S means that it has rear suspension. In fact, it is a normal touring 500-cc Single with rear suspension.

(Continued on page 22)

To my knowledge no AJS or Matchless motorcycles of this vintage were produced with twin spark plug cylinder heads. Neither do I know of any factory specials that were produced with this arrangement. If the machine is to be used with the standard compression ratio, there is no advantage in the additional spark plug. However, if an ultra-high compression ratio were to be employed, the extra plug could prove beneficial, particularly if the combustion chamber was of unfavorable shape (not very compact).

The early AMCs (Matchless and AJS) were produced with Burman gearboxes. In the early 1950s, the manufacturer changed to a gearbox of its own design and manufacture. The later box was better and stronger in most respects, but did not have quite as positive a change mechanism as did the early assembly. The early box can be identified by the die cast change quadrant that housed four helical springs. The late model had a flat C spring that controlled the change mechanism. The early Burman box was made specifically for AMC and, to my knowledge, the internals of other Burman boxes would not inte rchange.

AJS stands for A. J. Stevens who was the manufacturer before the firm became amalgamated with Matchless.

Matchless has produced some very advanced machines. As early as 1931, the company built the Silver Hawk, which was a narrow angled V-4 (26°); the valves were operated by a single overhead camshaft which was driven by a vertical drive shaft. It had a bore of 50.8 mm and a stroke of 73.02 mm, resulting in a total displacement of 593 cc. It was advertised to possess "stupendous acceleration and a maximum speed of over 80 mph," which really was honking in those days.

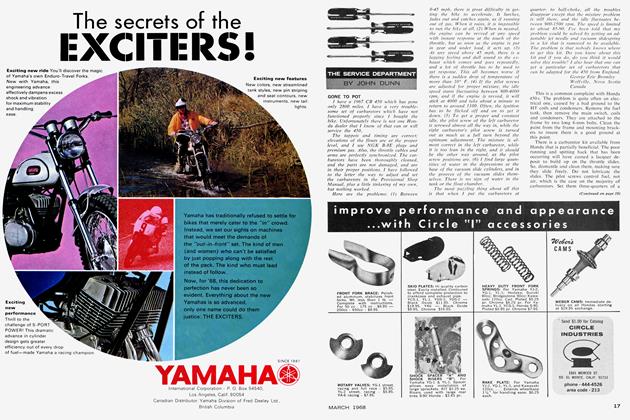

ON THE COLD SIDE

I have a problem with my Honda S-90. In cold weather, my carburetor slide freezes up. It gets stiff around 45 F, and gets impossible below 35 F. It seems better if the bike is fully warmed up (sitting for 5 min., then ridden for a while), but usually I ride 5 min. at one stretch. As it is 20-35 F up here now, it is impossible to ride the bike. Even in the summer, I had the problem of the throttle jamming in the open position — very uncomfortable in city traffic!

The slide is in pretty rough shape — nicked, scratched and looking like it has been sanded (hard for a chrome surface).

I bought the bike used. Since it is nearly impossible to get individual carburetor parts here, I have tried other approaches. I have used fine valve grinding paste to get a smoother finish in the slide cylinder, and at the same time to bore it out. Because there is a pin about halfway down, I was limited to using my finger as an applicator for the paste. I got a good surface, and after washing it out with gas, I tried the slide again. It worked okay at room temperature, but outside, where it cooled to 25 F, it stuck again.

What can I do? Would a more radical boring out of the cylinder help? If I must get a slide, is it ethical to order one from some U.S. Honda dealer, as I am in another distributor's area?

Also, is the slide meant to go all the way up the cylinder, or only to the ridge present in it?

Jerry Volkers

Winnipeg, Manitoba

Canada

I have heard of this problem before, particularly on the little Hondas with the long induction manifold. I do not know the solution to this problem, not having had any first-hand experience. However, it would be worthwhile trying one of the special lubricants that are on the market that claim to cure the sticking throttle slide. One that comes to mind is "Dry Slide," which, after being sprayed on, dries, leaving a coating that possibly has a graphite base. If any other reader has found the cure for a frozen up throttle slide, please let me know.

Once a throttle slide or carburetor body becomes badly worn, the only solution is to replace the faulty component. Overtightening the carburetor mounting flange often can result in a distorted carburetor body. Individual carburetor parts can be obtained for Honda carburetors. There is no reason why you cannot order the necessary parts from any Honda dealer in the USA, or in the world for that matter. When you order the parts, give full details of your machine and carburetor, including the name of the manufacturer as Honda now uses more than onp I suggest that you replace both slide and body.