THE SERVICE DEPARTMENT

JOHN DUNN

DEAF

I recently purchased a BMW R69S. I understand that I can get slightly more power and weight reduction by switching to mufflers with less baffling. I don’t mind the extra noise; however, I am told that carburetor will run lean when the back pressure is reduced. Is this true? If so, how can I arrive at a satisfactory fuelair ratio when changing from standard mufflers?

Ray C. Dixon

Charlotte, N. C.

The noise might not bother you, but how about everyone else?

Regarding your article, “Is it Worth It?” — I have come up with several questions.

(1) If the muffler were replaced by a straight pipe on a Honda S90, would the valve tappet clearance have to be increased or decreased?

(2) In an altitude of 6,100 feet, what slide needle setting should be used in the carburetor, and how many degrees should the timing be advanced for the coolest engine operation?

Richard Dixon

Montpelier, Idaho

There is no direct relationship between the type of exhaust system being employed and valve tappet clearance. The tappet clearance setting as indicated by the manufacturer should be used no matter what exhaust system is being employed. The specified tappet clearance is directly related to camshaft lobe profile design; any variation from the standard setting will have an adverse effect on the smooth operation of the valve train assembly.

Due to the lower barometric pressure at high altitude, it will be necessary to decrease fuel supply throughout the entire operating range of the engine to obtain the correct air to fuel ratio, because of the decrease in volume (weight) of air being inhaled. It will therefore be necessary for you to readjust your carburetor throughout the entire range to obtain a weaker mixture. At high altitude, even when correctly jetted, an engine will develop less power than it would at sea level. There would be no benefit obtained by advancing the camshaft timing as this would have no direct relationship with a change in altitude.

I would like to become a cycle mechanic and maybe someday own a shop of my own. But how does one get training for cycle mechanics? I would assume the best bet would be to take a course in combustion engineering.

Could you please send me any information you might have, or advice as to entering this field?

Bernard L. Freese

Waterloo, Iowa

Initially, it would not be necessary for you to take a theoretical course in automobile engineering. However, it would be of great value if you were to study the basic working principles of engines employing both the two and four cycle systems, including some knowledge of carburetion, ignition, generating, braking, suspension and transmission systems.

Practical training and knowledge can only be obtained by actual experience. At the present time, there is a great shortage of experienced mechanics throughout the country. I would suggest that you apply for a job as a mechanic’s helper on a trial basis.

The majority of motorcycle manufacturers or their agents provide instructional courses for dealers’ mechanics. Providing you show some promise during your trial period. I am sure the employers would be only too pleased to send you to the manufacturer’s courses.

(Continued on page 24)

LOUD CUB

1 own a ’60 Triumph Tiger Cub which suffers from a small, but very common ailment — noisy valve tappets. I adjust them constantly with a feeler gauge and by the manual, but seem to get nowhere. I have come to the conclusion that possibly no harm is being done by these loose tappets, but it still bothers me.

Could you please give your opinion as to whether this “slap” in the tappets is harmful to the machine? The only mechanical trouble encountered with the valves was when 1 missed second while running the “quarter” and bent the exhaust valve. Could this bent valve be linked with loose tappets? Other than this small ailment, I find my machine — contrary to popular opinion — to be very reliable and trouble-free, i.e., Cubs in general are not looked upon by the mechanically-minded to be up to par.

Turkey Foster Knoxville, Tennessee

Most Tiger Cub models have a tappet clearance of 0.010" for both the intake and exhaust valves. However, certain T20S models were fitted with a sports camshaft where the clearances are indicated as being 0.002" on the intake and 0.004" on the exhaust. With the standard or sports camshaft, the tappet clearances should be set or checked with the engine cold and the piston should be on TDC on the firing stroke. Not knowing the model of your machine, it may be possible that it is fitted with the sports camshaft.

The bent exhaust valve may have been caused by incorrect tappet settings or by simply over-revving the engine.

OIL LEAK

ƒ have been riding motorcycles for 19 years. I am on my second Honda 305 Dream. The first Dream, a 1964, went 15,000 miles and developed an oil leak at the seal behind the alternator. It was replaced and was O.K. at 24,000, when I traded it for a new 1965 model. This same seal started leaking at 5,000 miles. It was replaced; however, it started to leak again at 6,500 miles.

What is the cause and how can it be corrected?

R. H. Talbert Greenfield, lnd.

The trouble being experienced is a common complaint on late model 250 and 305cc Honda machines, and is normally cured by replacing the timing side crankshaft and starter sprocket oil seals. It is essential that they are carefully installed; even very slight misalignment will cause the leak to persist.

BEWARE

1 own a Honda S-90 and 1 plan to install a Harman & Collins racing cam, along with S.W. racing valve spring from Webco Inc. 1 would like to know if a larger carburetor would be needed, and, if so, is there a Honda carb that would fulfill the job without much modification, or any carb, for that matter?

(Continued on page 26)

Byron Lussier

Lander, Wyoming

A large increase in carburetor size would be of no benefit, unless the intake valve and port have been enlarged to suit. A small increase in carburetor size may be of slight benefit, providing the intake port is matched to suit the larger carburetor bore size. Honda employs many carburetors of varying sizes, which are similar in operation.

The racing cam and high frequency valve springs will prove beneficial in terms of greater horsepower without a change in carburetor size. However, to do full justice and take advantage of the new cam, it would be necessary to increase the intake valve, port and carburetor bore sizes. A large increase in valve size should not be carried out, unless one is confident that mass air flow is not impaired due to cylinder wall or piston crown restrictions. Port shape is also critical and a slight error in judgment may result in an adverse condition and less power, due to poor directional flow and fuel distribution. The existing port shape has been arrived at by scientific research, to promote good conditions over a reasonable speed range. Without the aid of flow equipment, it is good practice to stay within the original basic shape when the cross-sectional area is being enlarged. Any sudden variations in cross-sectional area should be avoided, as this can allow a sharp change in gas velocity to occur with the adverse effect of fuel precipitation. This would result in power loss or misfiring on or near full throttle, due to a wide variation in the correct air/fuel ratio. It is, therefore, most important that porting or any reshaping of the intake port should receive careful consideration beforehand.

Final decision regarding the best compromise for carburetor choke size is determined by conditions related to gas velocity, both at low engine speed and maximum engine speed. The decision here will mainly depend in what type of event the machine will be used. At maximum engine speed, when set up for maximum performance, it is not advisable to exceed a gas velocity of over 300 ft/sec. Conversely, when low end or mid-range torque is of importance, a gas velocity of 60 ft/sec. should be considered minimum at low operating speeds.

The relative proportions of the intake system is a subject that has been touched on by a great many people and delved into by a few. There is no definite set of rules that can indicate the optimum requirements, because each individual engine design can only be dealt with on its own merits.

BETTER FOR RACING

Would you please tell me the advantages and disadvantages, both in performance and maintenance, of the overhead camshaft?

1 have heard that engines with overhead cams rev more freely than push rod engines. Is this true?

Eldon Cook Baton Rouge, La.

(Continued on page 28)

One could write a lengthy book on the advantages and disadvantages of the overhead camshaft, when compared with the pushrod-operated valve train mechanism. It is difficult to cover all aspects within the medium of this letter. The type of valve train mechanism used is greatly influenced by basic engine design and intended use.

When one considers an engine for all-out competition purposes the ohc system is undoubtedly the best, due to the very high mechanical stresses involved.

However, for normal touring or mild sporting activities there is no advantage to be gained. Generally speaking, the pushrod engine is easier to maintain. The cylinder head can be removed without disturbing the valve timing, etc. Resetting the valve timing on many engines employing an ohc can prove very complicated and difficult for the average owner. There are exceptions though, the method used by Honda on all their ohc street machines being very simple.

So as you can see, it is difficult to generalize on this subject without having certain preferences in mind.

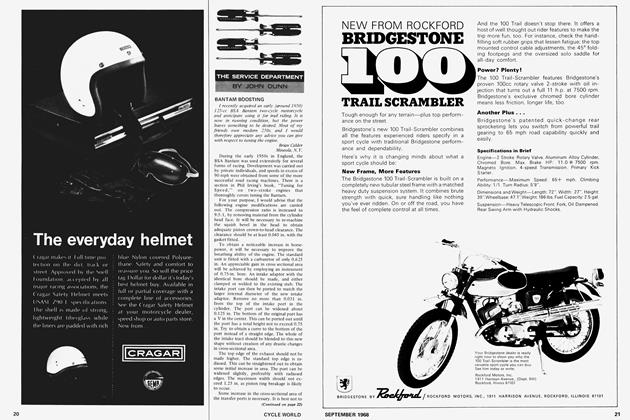

HONDAKA?

I am enclosing pictures of a conversion 1 recently completed on my Honda “90” CT-200. The Hodaka front forks greatly improved the handling qualities both on and off the road, particularly in the dirt, as 1 had the forks altered to a 6" travel. The transition lengthened the wheelbase approximately 3" and the maximum ground clearance 2". Doing everything myself, except altering fork travel, and using all of the original Honda parts 1 could, the total cost was $109.00.

I have bored the cylinder to a 3rd oversize 160 piston in an attempt to achieve a little more power and top end. The next step 1 know is to improve the breathing. Please give me some clues as to:

1. What carburetor would work best? (possibly a C-ilO?)

2. Would a Harman & Collins cam using the stock valves improve this little engine much?

3. Could Webco valve springs be used without harming the stock cam?

4. What should the ignition timing be set at (point gap and advance) to be tuned to your recommendations on above questions?

5. I have unsuccessfully tried to obtain a motor manual for the CT-200. Do you know of any publications pertaining to my engine?

Larry Arnot

Duarte, Calif.

(Continued on page 32)

We thank you for the enclosed photograph of your machine. The Hodaka front fork installation looks very neat and in keeping with the proportions of the machine.

A combination of the Harman Collins cam and Webco valve springs would be well worth considering. A reasonable increase in overall performance should be expected without detracting from the engine’s present torque characteristics.

A small increase in carburetor choke size may be beneficial; conversely, a large increase would definitely be detrimental. Ignition timing should not be influenced by cam timing. Therefore, we would suggest that you stick to the standard recommended settings. American Honda Motor Company, Inc., 100 W. Alondra, Gardena, California, can supply you with a manual.

NEW TWIST

Tm a Triumph rider and I’d like to say that the high revving 650 BSA is too hot for Triumph 650s. But I got them fooled. 1 took a Triumph 500 (stroke 64.4mm), installed a 650 barrel after much work, and came up with 71 /65.5mm bore/stroke without boring. 7200 vs. 8000 rpm. Those revs mean a lot.

Also, could you tell me how to find cubic centimeter displacement from a millimeter bore and stroke?

Dennis Quackenbush Cicero, Illinois

Your method of employing high rpm is good. The limiting mechanical factor at high rpm is governed by maximum piston acceleration and is influenced by the stroke and con-rod length. Retaining the short stroke was wise thinking. However, one must remember that it is useless to employ high rpm if the engine is unable to breathe sufficiently at the higher speed. An increase in intake valve, port and carburetor size could be of advantage in your case.

To find the cubic capacity of a cylinder when the bore and stroke are given in millimeters the following formula should be used:

C — '7TV' X L when

C — capacity in cubic centimeters

vr = 3.14

R = Radius of cylinder in centimeters

L = Length of stroke in centimeters (10mm = 1 cm)

PISTON PROBLEM

ƒ have a 1960 BSA 650cc Super Rocket. 1 wish to purchase a set of 10:1 pistons from a friend. The pistons are .060” oversize and my friend says they will be perfect. But some mechanics say that my bike will only handle pistons .040 and under. Would you please inform me whether 1 can use these pistons and have my cylinders rebored or should 1 buy new pistons (10:1) standard size?

John McLeod

Ontario, Canada

If your cylinder bores are standard at the moment it appears that to have them bored to .060" oversize would be unwise. However, this is a matter of economics on your part. The price you are paying for the .060" oversize pistons has an influence on your decision. You can consider that .060" is the maximum oversize that this cylinder can take, and bear in mind that mechanical reliability is at stake.

(Continued on page 34)

Premature piston seizure is much more likely to take place with the thinner cylinder wall and higher compression ratio. I would personally favor the standard size providing the bore is in good condition, and would suggest that the cylinder be lightly honed to assist the piston ring break-in period.

THAT'S A LOT OF--.

/ own a 1966 Bridgestone I75cc, 20 lip, 5-speed, dual twin motorcycle. It will do 82 mph without the extras. Can you tell me if there is anyway I can soup it up to 200cc or at least so it will do 95 mph? That is with a fairing, carrier, saddlebags and extras.

I have 720 miles on it now, and I want to see if I can ride it down to Florida this August. This is why I want to know if I can soup it up to do at least 90 mph plus. It weighs 281 pounds. Do you think 1 could make a round trip of 1,200 miles on it?

I’ve been told you people are experts on these matters. I don’t know very much about souping motorcycles as yet. I have the money for souping it if needed.

Paul Scaruffi Chicago, Illinois

The Bridgestone 175 Dual Twin is already a very highly-developed machine. You would risk losing performance by altering the engine any large amount. You would certainly sacrifice reliability, and since you plan a long trip, we would suggest you resist the urge to tinker.

QUICK AND QUIET

I would like to inquire into a few facts about my bike, a 1965 Honda 300 Dream with 5,700 miles. The performance of the bike is very good, testing it against the same model, and I have noticed that with the baffles removed and adjusting the curb, my performance is exceedingly good. My question is, does this affect the valves in any way, and is there a chance of them becoming warped? If this is the case, could you inform me on other ways of increasing the performance?

Wayne Lapawchuk

Spirit River, Alberta, Canada

Providing the carburetor is correctly rejetted, the removal of the muffler diffusers will not adversely affect the condition of your exhaust valves.

It is debatable whether baffle removal does improve machine performance. No recorded comparisons have ever been published (to my knowledge) to highlight this point.

We must point out that we do not applaud exhaust system modifications which result in an increase in exhaust noise level when the machine is to be used on the street.

As a point of interest regarding exhaust baffle removal and its effect on performance, I personally made the following first-hand observation during the first Silverstone (England) 1,000 km production race. Two stock, well prepared, CB72 Honda 250 Hawks were competing. They were identical, except that one had the exhaust diffusers removed and rejetted to suit. For the first 100 miles, until one got ahead by a quicker pit stop, there was “nothing in it.” Both machines were lapping consistently at just under 80 mph. Performance and rider ability being very comparable and both machines being ridden very near their maximum potential, I am positive that no difference in performance was apparent, because I was riding the machine with baffles and a good friend was riding the other. We were both trying very hard and passed and repassed each other repeatedly during the first 100 miles. If my machine had not been as good or better, I could not have stayed with him.

Keep your machine in good condition with the baffles fitted and you will go just as quick.