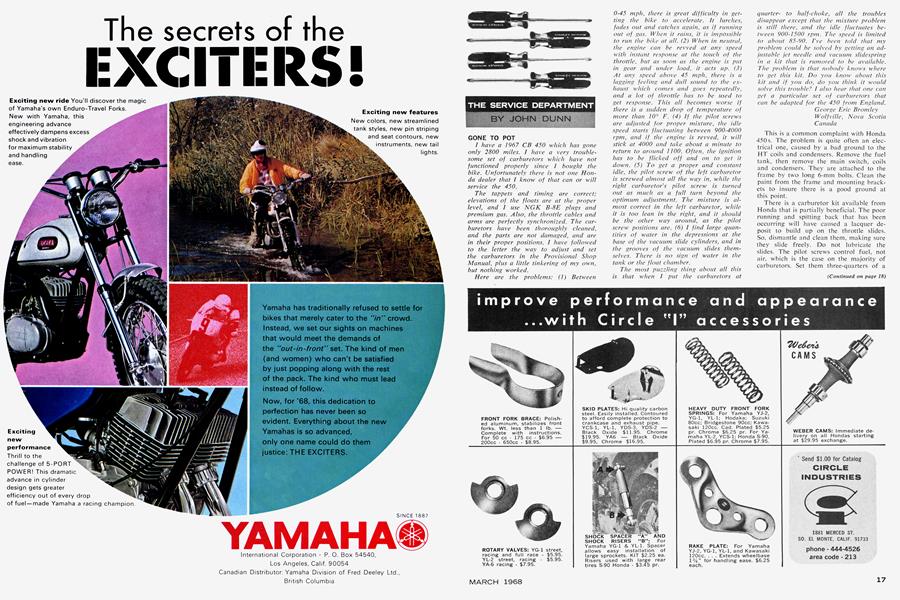

THE SERVICE DEPARTMENT

JOHN DUNN

GONE TO POT

I have a 1967 CB 450 which has gone only 2800 miles. I have a very troublesome set of carburetors which have not functioned properly since I bought the bike. Unfortunately there is not one Honda dealer that I know of that can or will service the 450.

The tappets and timing are correct; elevations of the floats are at the proper level, and I use NGK B-8E plugs and premium gas. Also, the throttle cables and arms are perfectly synchronized. The carburetors have been thoroughly cleaned, and the parts are not damaged, and are in their proper positions. I have followed to the letter the way to adjust and set the carburetors in the Provisional Shop Manual, plus a little tinkering of my own, but nothing worked.

Here are the problems: (1) Between 0-45 mph, there is great difficulty in getting the bike to accelerate. It lurches, fades out and catches again, as if running out of gas. When it rains, it is impossible to run the bike at all. (2) When in neutral, the engine can be revved at any speed with instant response at the touch of the throttle, but as soon as the engine is put in gear and under load, it acts up. (3) At any speed above 45 mph, there is a lagging feeling and dull sound to the exhaust which comes and goes repeatedly, and a lot of throttle has to be used to get response. This all becomes worse if there is a sudden drop of temperature of more than 10° F. (4) If the pilot screws are adjusted for proper mixture, the idle speed starts fluctuating between 900-4000 rpm, and if the engine is revved, it will stick at 4000 and take about a minute to return to around 1100. Often, the ignition has to be flicked off and on to get it down. (5) To get a proper and constant idle, the pilot screw of the left carburetor is screwed almost all the way in, while the right carburetor's pilot screw is turned out as much as a full turn beyond the optimum adjustment. The mixture is almost correct in the left carburetor, while it is too lean in the right, and it should be the other way around, as the pilot screw positions are. (6) I find large quantities of water in the depressions at the base of the vacuum slide cylinders, and in the grooves of the vacuum slides themselves. There is no sign of water in the tank or the float chamber.

The most puzzling thing about all this is that when I put the carburetors at quarterto half-choke, all the troubles disappear except that the mixture problem is still there, and the idle fluctuates between 900-1500 rpm. The speed is limited to about 85-90. I've been told that my problem could be solved by getting an adjustable jet needle and vacuum slidespring in a kit that is rumored to be available. The problem is that nobody knows where to get this kit. Do you know about this kit and if you do, do you think it would solve this trouble? I also hear that one can get a particular set of carburetors that can be adapted for the 450 from England.

George Eric Bromley Wolfville, Nova Scotia Canada

This is a common complaint with Honda 450 s. The problem is quite often an electrical one, caused by a bad ground to the HT coils and condensers. Remove the fuel tank, then remove the main switch, coils and condensers. They are attached to the frame by two long 6-mm bolts. Clean the paint from the frame and mounting brackets to insure there is a good ground at this point.

There is a carburetor kit available from Honda that is partially beneficial. The poor running and spitting back that has been occurring will have caused a lacquer deposit to build up on the throttle slides. So, dismantle and clean them, making sure they slide freely. Do not lubricate the slides. The pilot screws control fuel, not air, which is the case on the majority of carburetors. Set them three-quarters of a turn open initially, then set the idle screws. It may be necessary to readjust the pilot screws slightly to obtain the best compromise. They should end up somewhere between three-quarters and one and one quarter turns open. T am not aware of the English carburetor that has been successfully adapted for use on the Honda 450.

(Continued on page 18)

STEP PINS

In reference to your comments on step pins (CIV, Dec. '67), we have found these to be some of the major problems:

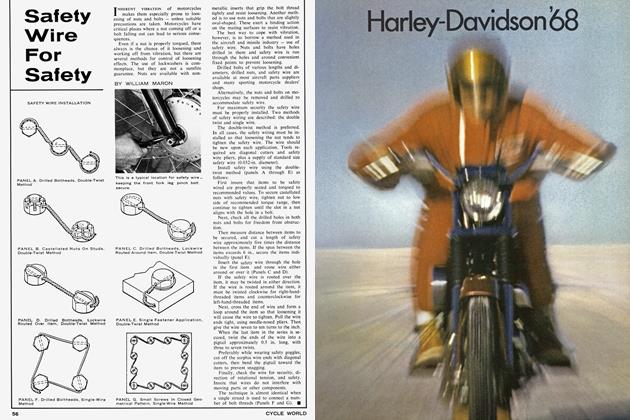

Maintaining absolutely true centers throughout the sequence of manufacture appears to be the prime difficulty. Centers can be slightly misaligned during the machining phase; they can shift slightly during the heat treating. These same centers must be relied on when grinding the pins to their finished size. If there has been any deviation whatsoever, it follows that the step portion of the pin will not be precisely parallel with the ends. From our specialized work in this field, we have concluded that it is not economically feasible to produce a step pin guaranteed to be 100 Dercent free from this problem of wandering centers.

The consequences of this are that the piston end of the rod magnifies any deviation in the "parallel-ness" of the step, resulting in tipping of the rod (proportionate to the degree that the step is out). When rod bearing clearance is not sufficient to compensate for this, the needles climb to the "uphill" side, forcing the retainer (see enclosed drawing). The resulting friction can cause seizure from a melted retainer. Or if heat doesn't do it in, mechanical stress on the retainer will cause release of the needles — again resulting in bearing failure.

Neither of these problems is related to splitting of the bearing retainer, providing it is accomplished in a manner which prevents loss of the needles. Powroll's technique is basically this: We notch the retainer, then place it on a split fixture which expands on a tapered cone under impact. This splits the retainer and expands it at the same time. Then the two pieces are contoured and fitted to conform with their original shape without a gap and to idle properly within their confinement. Because we do the complete assembly, we have direct control over critical sizing of the pin and needles. Pins and needles are catagorized in 0.0001-in. increments. This assures arriving at a correct clearance, and maximum dependability. Then each rod assembly is checked for run-out to meet our tolerance before being pressed into the counterweights.

Powroll has developed a totally new stroking procedure which eliminates step pins and split retainers, but I want to emphasize that the overwhelming majority of our earlier step-pin stroker kits have given their owners reliable service. Almost without exception, abuse and misuse have been directly responsible for those kit failures brought to our attention.

Paul S. Olmstead Powroll Performance Bend, Ore.

You have clearly indicated the importance of having a precisely engineered and manufactured roller bearing assembly. I am surprised, however, that a stepped crank pin cannot be economically manufactured to the close tolerances required. I would have assumed that all surfaces could be finish ground on the same centers after hardening and heat treat.

Your company obviously consists of people interested in improving the product.

(Continued on page 20)

The fact that you have developed a method of increasing the stroke without resorting to the stepped pin principal demonstrates a genuine effort to provide the ideal solution. I assume the desired effect is achieved by employing a larger diameter crank pin and machining the flywheels to suit.

VIBRATION AND NO POWER

Can you tell me why my 1966 BS A Spitfire Mark II vibrates badly at around 5000 rpm and will not pult in top gear without the engine running hot and "pinking?" The bike lacks power in the high gears, misses and splutters and almost cuts out altogether.

Where should 1 look to get to the root of the trouble. Can I simply alter the ignition and carburetion settings or should the complete engine be stripped?

John Salter Bangor, Maine

I would suggest you first recheck the ignition timing using the static method. It is best to set the timing when the automatic advance mechanism is in the fully advanced position. The correct timing when fully advanced is 34 degrees btdc. BSA supplies a special tool in the tool kit for locating the crankshaft at 34 degrees btdc. There is an aperture in the front of the right crankcase which is covered by a small plate. Remove the plate and insert the special tool. Turn the crankshaft until the tool is felt to engage in the flywheel. Secure the tool in this position. It is important that the crankshaft is not turned with the tool in position. Next, check which cylinder is on the compression stroke. The cylinder with both valves closed will be on compression. The top set of contact points are used with the right cylinder, and the bottom ones with the left.

To set the timing accurately, connect a battery and bulb in circuit with the points. Connect one side of the battery to the pivoting contact or contact leaf spring, making sure that it is not grounded. Connect the other side of the battery through a bulb to a suitable ground on the engine. When the points are closed, the bulb will light. Proceed to set timing as follows:

(1) Set the right-hand cylinder on compression, and use top set of contact points.

(2) Check and set the point gap to 0.015 in. This should be checked with the points fully open.

(3) Slacken the contact breaker back plate screws so the back plate can easily be turned. Do not slacken the screws more than required.

(4) Turn the contact breaker cam in an anti-clockwise direction into the full advance position and hold it there. Then, rotate the back plate until the points just start to open (light goes out). Tighten back plate screws and recheck.

(5) Remove special tool and rotate crankshaft 360 degrees, then replace tool. The left-hand cylinder will now be on compression.

(6) Check the timing on the left-hand cylinder, using the lower set of points. Do not slacken the contact back plate retaining screws. Just check timing by ro-

(Continued on page 22)

tating the cam into the full advance position. The light should go out at the same time full advance is obtained. If the lefthand cylinder is slightly out, the correct timing can be obtained by varying the points gap. For each 0.001 in. that the points gap is increased, the timing will be advanced one degree. Closing the points will have the effect of retarding the timing.

What type (heat range) of spark plug are you using? If the plug is too hot, this will most likely cause pre-ignition, and also will mislead you when taking plug readings. The correct plug for your machine is an N 3 Champion or equivalent.

According to the information that I have, the 190 main jet you are using is far too small. It is recommended that a size 260 or larger be employed. However, before attempting to tune the carburetors, first check and adjust the float chamber fuel level. Also, check that both the throttle slides start to lift at the same time, and that they both obtain full throttle. There is a small booklet available from your BSA dealer that fully describes the operation and tuning sequence of the Amal GP2 carburetors fitted to your Spitfire.

It is characteristic of the big BSA twins to have a vibration period. However, the extent of vibration should not be intolerable. Check that all engine mounting bolts are tight. The factory balance 70 percent of the reciprocating weight on all their big twins. It may be worth the trouble of having your engine dynamically balanced to the same factor (70 percent), or it may be worth changing the factor to either 60 or 80 percent. The latter could have the effect of moving the vibration period to another rpm range that is more acceptable. If you have the time and the money, it could be well worth trying.

Any of the above tips also apply to BSA's 1967 Spitfire Mk III.

IT ISN'T O.J.

/ just purchased a used '67 305 Honda Scrambler in Sept. and have only put on about 600 miles (1795 total) since 1 got it. It seems as though I have acquired a short in the wiring, but I'm not sure. I burnt out the taillight and headlight because of the tremendous amout of "juice" it was getting from somewhere. Now, when I start it, if 1 start it, the neutral light is real bright and flickers as the engine turns over. The engine also misses when not revved up and usually dies. / would like to get it fixed before winter, as 1 plan to ride it and would like it to start. What's wrong?

Larry Matt

Stillman Valley, 111.

It is almost certain that your machine has a defective battery. There is probably an internal break or bad contact between the cell connectors that is causing a high resistance in the electrical system. This will cause a voltage rise, that will burn out bulbs, and cause the neutral light to be brighter than normal. It is quite a common complaint on Hondas, and can be quickly checked out by trying a known good battery.