THE SERVICE DEPARTMENT

JOHN DUNN

Due to the tremendous volume of Service Dept. mail, we are unable to reply to individual letters. We shall continue to answer as many as space permits in this column.

VALUE OF HONING

After boring a cylinder, do you consider it necessary always to hone the cylinder? Also, a machine tool company's representative says without a doubt that a properly ground-in valve seat and a replaced valve will give a better seal than hand lapping the valve to the seat after grinding. He claims that when the engine is at running temperature, the valve expands at a different rate and would slightly move out of this hand lapped groove. This sounds logical and we tried it and it wouldn't seep any gasoline poured in the ports. Your opinion will be appreciated.

Ray Schuly South Bend, Indiana

A correctly honed cylinder bore does speed up piston ring "break-in" time and is of particular value when a chrome top ring is used. It is important that ring break-in time is kept to a minimum, because until this has been achieved, high oil temperature will prevail. During the initial period of an engine's life the lubricating oil is pressed to its structural limit.

Under ideal conditions and when using first class equipment it is true that a reground seat and valve face will seal without lapping. However, it is good practice to lightly lap the valve to its seat to give an indication of the effective seat width and its position in relation to the valve diameter. Even when using a good seat grinder it is possible that the new seat may not be concentric with the valve guide, due to a worn guide, worn stone mandrel or that the operator is applying an unrealized side pressure, causing the stone to cut off-center. A ridge, caused by over-lapping the valve could cause misalignment due to the different expansion rates of the head and valve, but this would only result if a poor valve job had been carried out in the first place.

IT'S WEIRD, MAN

Recently 1 saw about a 1959 or 1960 Triumph 650cc that looked rather weird; it had the head turned around backwards! The carburetors were mounted in the front and the exhaust in the back. 1 was wanting to know if it gave any boost in horsepower or if it was done that way just to be different. Also, is there much machine work required to do this?

Mickey Walters North Carolina There is nothing to be gained in the way of increased horsepower by fitting the cylinder head on backwards. It is most likely that the owner of the machine just wanted to be different. Turning the head around is a simple job. The camshafts can be interchanged without adverse effect as thev both rotate the same direction on a Triumph. However, the reason exhaust pipes face forward is to get maximum fresh air to the hottest part of the engine.

MORE JUICE NEEDED

I own a BMW R60 with Steib sidecar that 1 want to use for camping and trips. 1 would like to know if I can use a higher amp battery without damage to the wiring or generator. I wish to keep a 6-volt system for lights 1 intend to add. The regular 16 amps isn't enough. Would 1 need adjustments on the regulator or different gauge wiring? 1 want to use an imported car size battery of 60 amps.

Joseph E. Henault Hartford, Connecticut You can certainly use a larger amp/ hr. 6-volt battery without incurring any damage or distress, to your charging circuit. It will not be necessary to increase the load-carrying capacity of the wires. If your regulator and cut-out unit are correctly set, no further adjustment will be necessary. A battery is only a means of storing electricity and, providing the larger battery was fully charged, you would simply have more available current; total lighting and ignition demands remain the same. If, by fitting extra lights, your load demand was higher than the maximum output rating of the generator, a continuous drain on the battery would result. If continuous night driving were maintained, the result would eventually be a flat battery, no matter how great its capacity. During daytime operation the load demands are light (only ignition in the case of battery ignition; this would allow the battery time to recharge.

(Continued on page 26)

HAVING HIS UPS AND DOWNS

1 am a recent convert to the motorcycle world having succumbed to the bug only a month ago. I am stationed in Japan and have recently purchased a 1966 Honda CL-72 250cc Scrambler produced for the Japanese market, e.g. speedometer in kilometers and a type 2 engine, etc.

The problem is that occasionally in downshifting from third to second the transmission just goes out of third but not into second and it is then necessary to rechlich and upshift and then downshift again. This happens maybe one out of every twenty times, when making a fast stop requiring some rapid downshifting and braking, or when turning a corner in third and then trying to downshift.

Generally it is just a minor inconvenience but trying to start from third gear in the middle of a busy Japanese intersection at rush hour is a rather interesting experience and 1 don't care to do it routinely.

The local Honda dealer doesn't know what is causing the trouble but since he speaks only a little English and I don't speak any Japanese there is a definite communication barrier. If you have any idea of what could be causing this downshifting difficulty, and probable cure, please write to me at your earliest convenience.

Capt. Leo C. Mulvihill U.S. A.M.C.J. APO San Francisco, California

The trouble being experienced with your CL-72 is not uncommon on any of the street 250cc or 305cc Honda machines. It can be partially overcome by careful attention to the alignment of the change lever fork in relation to the position and motion of the shift drum actuating pins.

If extreme force is used when the change lever is jammed between gears, distortion of the fork arm will result, which in turn will make matters worse. Generally, this fault is not so frequent when the machine has covered a few thousand miles. A sensitive feel, which is acquired with practice, can forestall jamming. Our road tests, incidentally, are carried out by very experienced riders and a fault of this nature would not be so obvious to them, due to their understanding (in most cases subconscious), feel and skill, as to a person just starting out in the motorcycle world. Many of us long for the day when all the good points found in various makes of machines can be combined in one reasonably perfect motorcycle, but remember, all aspects of engineering are a compromise in some respect.

(Continued on page 28)

A HAWK FOR ROAD RACING

I have a 1962 305 Honda Super Hawk (CB-77). I would like to fix it up for road racing. What are some of the ways 1 can get more power from the engine? It doesn't wind up as it should. It will run about 100 mph but it takes all day to get there. How can I make it top out faster? I know a larger rear sprocket would help, but how can I tune it to rev higher and faster? And if possible how should 1 set the carburetor needles? 1 also would like to know how to adjust the carburetor for more power. One more question — can you race this machine with stock mufflers without much power loss, or would it be better to take them off and just use the exhaust pipes?

Richard L. Phillips Brownwood, Texas

There is a great deal of performance equipment available for the CB-77, particularly when the machine is being prepared for road racing (Webco, Precision Machining, etc.).

In standard form this machine is definitely too highly geared. To obtain better acceleration it would be necessary to limit top end speed to around 90 mph.

The standard exhaust system is quite efficient and does not cause much power loss when set up for the street. To run on the front pipes only would be a mistake; they are even too short for any beneficial effect at maximum rpm. Honda can supply megaphone extensions for road racing use.

The carburetors will obviously have to be reset for a richer mixture if engine performance equipment and megaphones are installed. Start by getting the correct main jet size and then adjust the needle position to give clean throttle response when accelerating. The method of arriving at correct carburetor settings has been covered in this column several times.

DON'T MOVE IT

/ have been an enthusiastic admirer of Hondas for years, and of CYCLE WORLD for almost that long. To make this letter as short as possible, 1 have listed my questions below:

In December '65 CW, you had a trail test of the Honda Trail 90. "Honda rates the Trail 90 . . . with 6.0 hp @ 7,500 rpm. Valves, pushrods, camshafts, and several other things are rattling like crazy at this engine speed." Is this true of all single-cylinder Hondas, and is Honda aware of this?

(Continued on page 30)

While on the subject of the Trail 90, would it sound too unreasonable to move the carburetor to the other end of the hose supplying the air, thus giving the machine ram injection carburetion for better performance?

In the same issue, I am curious to know how many letters you have received regarding the number of cubic centimeters in Honda's new 305 Scrambler? Let's have more articles on the Honda CB-160.

Larry Botchek O mak, Wash.

Due to the flexure that exists in the pushrod-operated system, valve control is lost at engine speeds in excess of 7500 rpm, due to valve spring surge in this particular case. This therefore results in excessive mechanical noise, which was previously referred to by us as "rattling like crazy." As a point of interest it should be noted that the Honda S-90 which employs the overhead cam system is designed to operate to a maximum of 9500 rpm without loss of valve control. This system has less moving parts in the valve operating mechanism, thereby reducing flexure and cam follower deflection.

The relative position of the carburetor to the intake valve on the Trail 90 is chosen to induce good snap acceleration through good fuel atomization. Throttle response would be poor if the carburetor were positioned as suggested by you, and the overall performance impaired.

You were the only reader to remark on the incorrectly placed decimal point in our 305 test specifications.

We had a complete CB-160 road test in the May '65 issue of CW.

WOW!!!

I would like very much to have some information about souping up the Honda Super Hawk. Could 1 take a Harley transmission and mount it between the Honda engine and rear sprocket? Take the chain from the Honda engine and run it to the Harley transmission (it would be locked in high gear)? Then could I take a chain from the Harley transmission to the rear sprocket of the Honda? Would this give me more speed on the take off and through the quarter-mile runs? Or would it have more speed on the top end?

Anthony Woolever Orange, Texas

Your suggested transmission set-up would not be practical. In fact your line of thought should be promptly rejected as being ridiculous. There is nothing to be gained and much to be lost with this system. Even with the H-D locked in a direct 1 to 1 top gear ratio, extra mechanical losses would be incurred, not to mention the increase in weight of the machine. To maintain your existing ratio it would be necessary to install a clutch sprocket on the H-D box with the same number of teeth as the Honda gear final drive. On the H-D box final drive output shaft a sprocket with the same number of teeth as the Honda rear sprocket would be needed. If the present sprocket sizes on the H-D box were retained the overall gear ratio of the machine would be approximately 16.0 to 1. To change your overall gear ratio, Honda supplies extensive ranges of rear wheel and gearbox final drive sprockets.

IN MOTHBALLS

I purchased a 1965 Triumph Bonneville in July of 1965. It will probably have less than 6,000 miles on it at my time of enlistment, and considering the investment I would hate to sell it so soon and take such a large loss as I undoubtedly would. (Not to mention that I love the bike, she's perfect in every way.) So my first question: In what way would you recommend to store the bike for up to four years? Could it be dismantled if left intact, or would it be worthless left sitting so long? If the engine were left intact, would the external parts "freeze up"? Have you had any similar cases before, where the motorcycle was to be left alone for a prolonged period of time?

Mike Siena West Covina, Calif.

During World War II there were many instances where motorcycles and automobiles were stored successfully for long periods of time.

The most important thing to guard against is corrosion, which is mainly influenced by temperature changes and the degree of humidity. The machine should be stored in a dry, undisturbed place, which is protected from direct sunlight. It is best to remove both wheels and hang them up to prevent tire damage or distortion occurring. Protect all external surfaces of machine with grease or a suitable brand of rust preventing fluid. It is preferable that the engine is turned over several times at least once every three months. If this is not possible, position the pistons at bottom center and fill each cylinder with a medium grade oil. Before doing this, drain all the old oil out of the engine and flush with a suitable brand of flushing oil. The old oil will condition corrosive substances caused by combustion, etc. Drain the fuel tank and apply rust preventative to the inside surfaces.

Remove battery and thoroughly clean away any corrosion that may exist on the battery carrier or adjacent parts of machine. It is very difficult to store a battery for the period you suggest. It would be best to sell the battery if this is possible.

Remove the carburetors and clean thoroughly before packing away in a suitable box. Lubricate intake tracts and cap them off. Remove exhaust pipes and store separately. Lubricate exhaust ports and also cap these off. Wrap the machine and components you have removed in a tough plastic material, and it may be a good idea to leave the rear chain immersed in a sealed can of oil.

CONFLICTING ANSWERS

Concerning a 1965 Triumph TR-6, when adjusting the points to just open, should the piston be at 1/16" BTC? 1 have had several different answers, even from the factory. This is tuned for street use.

(Continued on page 98)

Walter M. Zwarich Prairie Village, Kansas

Before attempting to retime the TR-6 ignition, it is best to first remove the contact breaker assember and check the automatic advance on this unit. Correct amount of advance for your machine should be 12 degrees. Due to the difference in rotational speeds of the contact breaker cam and the engine crankshaft (contact breaker cam runs at half engine speed), this would mean 24 degrees of automatic ignition advance at the crankshaft.

The factory recommends a total of 39° ignition advance (degrees at crankshaft). Therefore with the engine stationary (static), initial timing will be 15° (15° + 24° = 29°).

On this particular engine 15 crankshaft degrees before TDC would be .068" of piston travel. If you intend to set the timing against piston position, .068" can be taken as 1/16", which is actually .0625". The points should be just breaking when the piston is in this position. This method of timing the ignition is accurate enough for normal use providing extreme care is taken. However, when the machine is to be used for racing, it is preferable that the ignition advance be set by crankshaft degrees, using a timing disc atached to the crankshaft.

It is important that the timing is checked on both cylinders and to obtain complete accuracy it may be necessary to alter the pont gap on one or both cylinders. To allow for any discrepancy in this respect, the factory suggests that a minimum of .010" and a maximum of .019" contact point gap may be used. The recommended normal contact gap is .016".

SPEEDO PROBLEM

For some time now I have been trying to get the speedometer on my 1964 BS A apart to repair it. It is a Smiths magnetic type with the large rubber rim that the speedometer fits into.

Through one of the advertisers in CYCLE WORLD I was able to obtain all but one part needed. The outside rubber rim is the part I need and so far have been unable to get one. 1 wonder if you could tell me what companies might have this part and if there is any substitute part that could be used. Thanks in advance for any help.

Bill Shepperd Frisco, Texas

Although the speedometer is manufactured by Smiths Instruments, Ltd., England, the rubber ring referred to by you is, in fact, supplied by BSA. The removal and replacement of the rubber ring can present a problem, and if care is not taken the instrument can be easily damaged. It is suggested that the speedometer be held end-ways, carefully, in a smooth-jawed vice, and the rubber ring pried off with a soft tipped tool; such as a piece of hard wood, etc. It is also recommended that you use a lubricant between the rubber ring and the speedometer. A light oil or a liquid hand soap will do the job. The rubber ring is an interference fit on the speedometer and when installing the new ring use plenty of lubricant.

DEGREES TO INCHES

Would you please publish the formula for the relationship between degrees of crankshaft rotation and distance of piston travel, in reference to timing an engine. I saw this formula once and although I have often needed it, I have never been able to find it since.

Edward Cornell Hudson, New York

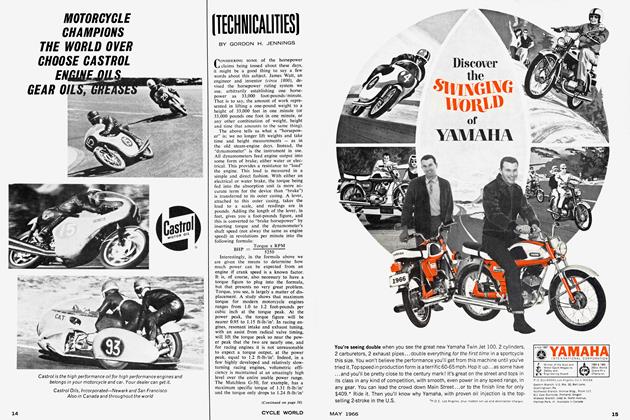

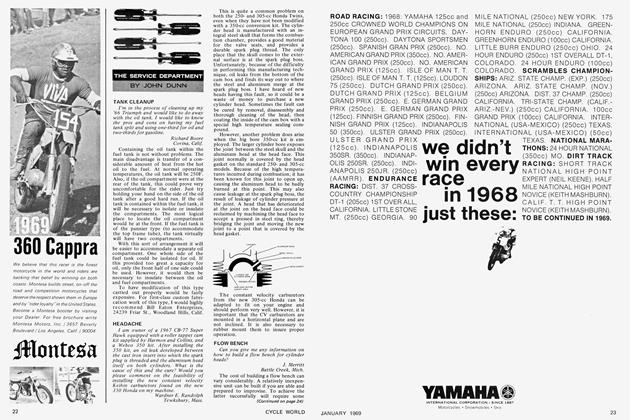

A simple method of determining linear measurement of piston travel from a given crank angle can be obtained by plotting a diagram with the aid of a drawing compass. First, draw a circle, the diameter of which is equal to the piston stroke. Then draw a vertical line through the center of this circle, of such length, that, with the compass now set to the same length as the connecting rod center, marks indicating top center and bottom center can be registered along its length. It is now possible to place one leg of the compass at any point on the circle and scribe an arc through the vertical line that is equivalent to linear displacement relative to top or bottom centers. Using an accurate scale you may measure directly from the vertical line without further conversion. Conversely, you may find degrees of rotation from linear measurement by scribing an arc through the circle from any point on the vertical line.

A = T.C. B = B.C. C = Ignition point (linear)

D = Ignition point (crank angle) From this drawing we can see that increasing the number of degrees before top center will also increase the measurement from A to C, or vice versa.