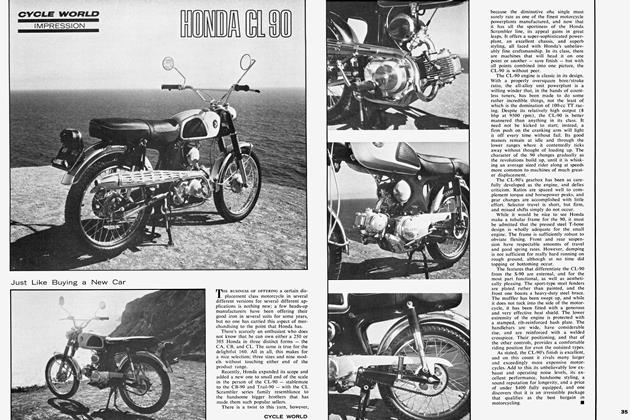

THE SERVICE DEPARTMENT

JOHN DUNN

WHAT? WHAT? WHAT?

I have a YCS-I with 5000 miles on it. For some reason, a hole was blown in the piston, causing it to seize and scar the cylinder.

I now plan to use J & R heads, Wiseco racing pistons, YDS-3C carburetors, and, because of the seizure, the cylinders will be bored out.

I would like to know if these modifications would be practical and what problems might arise:

How much should I have it bored out to? What size jets should be used in the curbs? What should the point gap setting be? What heat plug should be used? What would be the best bore and stroke? What should the compression ratio be? What effects would these modifications have on general performance?

/ am going more for quarter-mile e.t. than top end.

Norris L. West

Casa Grande, Ariz.

It is difficult for me to indicate what modifications would be practical when you do not clearly state what the intended use of the machine will be. If the machine is to be used mainly on the street, I would recommend the big bore kit, without any other changes. The present displacement of your engine is 75 cc. If the bore were increased from 47 mm to 50 mm, this would result in a displacement of 82 cc. An increase in jet size will be necessary. Tf the standard carburetor is used, I would suggest an increase of 10 to 20 in size. The final result can only be obtained bv testing. First, set the idle mixture and throttle stop to obtain a smooth tickover. Then ascertain the correct main jet by taking a plug reading from a good clean cut at maximum speed in top gear. If the engine does not respond well or cuts out during acceleration, this would indicate there was a lean condition within the part throttle range. This can be rectified by richening the idle mixture, reducing the throttle cut away, or by raising the throttle valve needle. Providing the compression ratio has not been increased, continue to use the standard NGK B-7HZ spark plug.

Although very simple from a mechanical point of view, the two-cycle engine is very complex when it comes to understanding the cycle of events required to produce high output or even a well-balanced unit suitable for street use. An increase in compression ratio generally is regarded as a sure means of increasing engine output. This is not always the case, particularly when the two-cycle is concerned. The modern two-cycle engine is a well-balanced unit, and one change, such as an increase in compression ratio, is capable of upsetting the applecart, resulting in a serious loss of power, combined with some very destructive effects.

The YGS-1 can be tuned to obtain a substantial gain in power output. If an optimum performance unit is desired, it can be obtained by carefully carrying out the following modifications.

(1) Compression ratio — A racing cylinder head can be obtained from Yamaha with a combustion chamber volume of 4.5 cc. This head is provided with a long reach spark plug hole, and it will be necessary to use either a NGK B-8EN or a NGK B-9EN spark plug. The standard cylinder head can be modified by machining 3.5 mm from the head face. If the head is machined, it also will be necessary to re-machine the squish area taper to insure adequate piston crown to cylinder head clearance. If the standard head (remachined) is used, it will be necessary to use either a NGK B-8HN or a NGK B-9HN (short reach) spark plug. A special piston also can be obtained from Yamaha that will suit this configuration.

(2) Cylinder and porting — A special aluminum cylinder with a chrome bore can be obtained from Yamaha. If this cylinder (chrome bore) is used, it will be necessary to use cast iron piston rings. Alternatively, the standard cylinder can be modified by increasing the height of the exhaust port by 3.5 mm, and the height of the transfer ports by 2 mm. Measuring from the top of the cylinder to the top of the exhaust port should result in a measurement of 26 mm, and to the top of the transfer port the measurement should be 32.5 mm.

(Continued on page 12)

(3) Rotary valve — A rotary valve with 147 degrees duration can be obtained from Yamaha. The standard valve can be modified to obtain the same timing, but it is suggested that the racing one be obtained because it is manufactured from more durable material.

(4) Carburetor and induction — Use a Mikuni VM 22 SC carburetor with a 260 main jet. No. 22 M stage three needle and a No. 2.5 throttle valve. It also will be necessary to obtain a special rotary valve cover, right crankcase cover, and carburetor cover from Yamaha.

(5) Right crankcase — It will be necessary to match the intake port in the crankcase to suit the larger induction system.

(6) Exhaust system — A complete expansion chamber type exhaust system can be obtained from Yamaha.

THREE-WHEELER FOR SNOW

1 own a 67 Honda CL 77 Scrambler and would like to put a third wheel on it for winter riding. However, I cannot find any information as to wheel placement, alignment, attachments point on the bike, etc.

Local dealers are unable to help me. Can you help me at all?

I own my own torches, etc., and have a rear wheel from a Yamaha, so / would prefer to build my own for cost reasons, but would like to see any commercial rigs that are available.

Two friends have just purchased similar bikes and would like to do the same thing, because this is our only means of transportation. Kipp Yule Madison Wis.

A well set up chair outfit (motorcycle and sidecar) is one of the most stable and controllable vehicles when operating on wet or icy surfaces. Driving a chair outfit calls for an entirely different technique than that used when riding a solo. At first the rider will feel that the sidecar wants to lift at the slightest provocation, particularly when negotiating a right-hand bend or turn (when the sidecar is right side of the motorcycle.) Turning left or right calls for entirely different techniques.

To obtain the best results, it is essential that the sidecar frame is well engineered, and will not flex under the high loads that occur when cornering. This applies equally to the method of mounting the sidecar wheel and also to the method of attaching the sidecar frame to the motorcycle. Also, it is important that the method of attaching allows for a generous amount of adjustment (this is required when lining the machine up properly).

I would suggest that you do not attempt to provide suspension or braking of the sidecar wheel. It is not necessary with a relatively light sidecar.

When laying out your design, place the sidecar wheel between 6 and 10 inches in front of the rear wheel (sidecar wheel axle 6 to 10 inches forward of the rear wheel axle). The CL 77 is better suited for mounting a sidecar than the CB models because it has a cradle type frame. It will be necessary to have at least four fittings between the motorcycle and the sidecar — two at the front and two at the rear. The upper front fitting, usually referred to as a “goose neck,” should be fastened to the front down tube of the motorcycle just below the steering head. The other end should attach to the outside front of the sidecar frame. The front lower fitting should fasten between the front inner side of the sidecar frame and the bottom of the motorcycle front down tube. This will result in a strong triangular structure.

A similar arrangement can be employed where the rear two fittings are concerned, with the upper one attached to the motorcycle frame just below the seat and the other end attaching to a point on the sidecar frame near the sidecar wheel mounting point. If a passenger-carrying body is not to be used, this is the easiest way of providing a strong method of construction. If a body is to be used, the two top fittings will have to be altered because they would pass through the body at a most inconvenient place.

It will be necessary to weld or clamp mounting points to the motorcycle frame to accept the sidecar fittings.

When constructing the mounts and fittings, it is important that sufficient adjustment is provided to allow for the following line up adjustments:

(Continued on page 14)

1. The sidecar frame should be reasonably level. A small rise or fall to the front or rear does not matter.

2. The toe-in or track width from front to rear should be capable of being altered. To achieve this, first line up the wheels of the motorcycle and then place a board (long enough to extend beyond the front and rear tires) along the wheels. Take a similar board and place it alongside the sidecar wheel. Then measure the track width just behind the rear wheel and just in front of the front wheel (the distance between the boards). The front measurement should be approximately 0.75 inch less than the rear one.

3. The motorcycle should be capable of being leaned from the vertical position either towards (lean-in) or away (lean-out) from the sidecar. It is usual to employ approximately 1 inch of lean-out. To achieve this, first stand the machine in a vertical position (employ a plumb line): then lean the machine away from the sidecar. Measure amount of lean from vertical at the top of the steering column.

All these figures are approximate, but will provide a good starting point. It may be necessary to alter one or all of them to obtain an outfit that handles well. If you have trouble initially negotiating right handers, do not lean the machine out so much. This will make the handling on left handers poor but not dangerous. Once you have developed a good technique on right handers, you will then be able to concentrate on setting the outfit up for good left-hand handling. Provided you are in the right gear, it should be possible for a left hander to be taken at full power without any navigational problems. The back end should come round in a full drift, and the machine should go in whatever direction you point the front wheel. If the front end tends to plow or understeer, you can correct this by employing more leanout or toe-in.

You will have to lower the gearing on your machine, also, and possibly stiffen up the front and rear suspension.

One word of warning: Do not attach the sidecar, in any way. to the rear suspension.

I would be very interested to know how you and your friends get on. If there are any points that you are not clear on, please let me know, because T feel this subject will be of interest to many other readers.

BREAK IN — NOT UP

I am going to buy a Ducati Mach I Racer in the spring and would like to know how I should break it in. Is there any difference in the procedure for a race machine as opposed to a street machine? The Madi I comes with a muffler and a megaphone. Would there be any harm in fitting the megaphone before the bike is completely broken in?

Also, l need quite a bit of information on the art of tuning. At the moment l can fiddle with the carburetor screw and adjust the timing, but I’m sure there is much more to tuning, especially race tuning, than that. Could you please fill me in on what tuning is, or exactly what it encompasses?

F. G. Cole London, Ontario Canada

Basically there are no major differences between breaking in a street machine and a full race machine. You are trying to obtain the same end result in both cases. Break-in is a period when initial wear takes place. No matter how accurately each component is machined, it is essential that they run together with adequate lubrication to form a full bearing surface. Roller and ball bearings are manufactured to a very high degree of accuracy, and therefore require a minimum of running together (break-in) to obtain a full bearing surface. Plain bearings take longer.

From a break-in point of view, on a motorcycle engine the piston, piston rings, and cylinder bore require the most attention. They do not only have to obtain a good bearing surface and provide a good gas and oil seal, but at the same time have to handle and transfer a great deal of the heat produced by combustion. During initial break-in there is a lot of heat caused by friction resulting from high unit pressures. If high combustion temperatures are added, piston, ring and cylinder failure is quite likely to occur. It is therefore essential that the two do not occur together. High rpm produces high piston speed, which in turn produces a high heat level caused by friction. Heat level caused by combustion increases proportionally to the load placed on the engine. Accepting that full load is obtained when the throttle is wide open, it follows that the more the throttle is opened, the greater the load. It is sometimes possible to run at fairly high speeds with the throttle only partially open (running down hill with the wind behind you). Combustion temperature will be low and friction temperature fairly high. If you try to go up a very steep hill in top gear, it will be necessary to open the throttle very wide. The heat generated by combustion will be excessive, causing severe thermal loading on the piston, rings and cylinder in particular. It is better to run at a medium engine speed than under high load.

(Continued on page 16)

Failure of any bearing is usually caused by excessive temperature and lubrication break down. Any surface that moves against another surface should be considered as a bearing. This includes all roller and ball bearings, valves and guides, cam lobes and lifters, piston and cylinder, small end bush and wrist pin. chain roller and sprocket, gear teeth and even the gear change actuating mechanism.

From the preceding, I hope you can see that break-in is a compromise that in practice is dependent upon a sense of feel, combined with a knowledge of what is going on.

Whether you break in your machine with or without megaphone is of no consequence, provided that it is jetted correctly, is in proper adjustment, and is ridden with respect and caution.

I believe that one of the most useful indications of how an engine is operating is obtained by observing the oil temperature. An excessive oil temperature is an indication of an adverse operating condition. A temperature taken in the oil tank or sump of 285 F should be considered as maximum.

If you buy a Mach I racer, it will already be in a high state of tune. The word tuning has many meanings and is not easy to define. However, in your case (with the March I racer) I would concentrate on keeping the machine in tip-top condition and proper adjustment. Only when you are obtaining the maximum performance as intended by the manufacturer can you contemplate and fully evaluate the potential of any additional modifications. ■

View Full Issue

View Full Issue