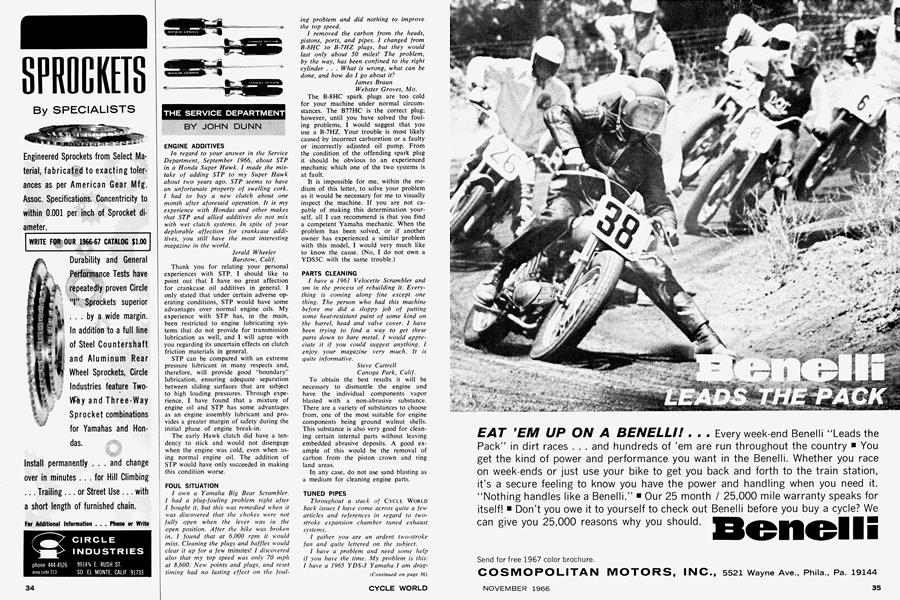

THE SERVICE DEPARTMENT

JOHN DUNN

ENGINE ADDITIVES

In regard to your answer in the Service Department, September 1966, about STP in a Honda Super Hawk. I made the mistake of adding STP to my Super Hawk about two years ago. STP seems to have an unfortunate property of swelling cork. I had to buy a new clutch about one month after aforesaid operation. It is my experience with Hondas and other makes that STP and allied additives do not mix with wet clutch systems. In spite of your deplorable affection for crankcase additives, you still have the most interesting magazine in the world.

Jerald Wheeler

Barstow, Calif.

Thank you for relating your personal experiences with STP. I should like to point out that I have no great affection for crankcase oil additives in general. I only stated that under certain adverse operating conditions, STP would have some advantages over normal engine oils. My experience with STP has, in the main, been restricted to engine lubricating systems that do not provide for transmission lubrication as well, and I will agree with you regarding its uncertain effects on clutch friction materials in general.

STP can be compared with an extreme pressure lubricant in many respects and, therefore, will provide good “boundary” lubrication, ensuring adequate separation between sliding surfaces that are subject to high loading pressures. Through experience, I have found that a mixture of engine oil and STP has some advantages as an engine assembly lubricant and provides a greater margin of safety during the initial phase of engine break-in.

The early Hawk clutch did have a tendency to stick and would not disengage when the engine was cold, even when using normal engine oil. The addition of STP would have only succeeded in making this condition worse.

FOUL SITUATION

I own a Yamaha Big Bear Scrambler. 1 had a plug-fouling problem right after 1 bought it, but this was remedied when it was discovered that the chokes were not fully open when the lever was in the open position. After the bike was broken in, 1 found that at 6,000 rpm it would miss. Cleaning the plugs and baffles would clear it up for a few minutes! 1 discovered also that my top speed was only 70 mph at 8,600. New points and plugs, and reset timing had no lasting effect on the foul-

ing problem and did nothing to improve the top speed.

I removed the carbon from the heads, pistons, ports, and pipes. 1 changed from B-8HC to B-7HZ plugs, but they would last only about 50 miles! The problem, by the way, has been confined to the right cylinder . . . What is wrong, what can be done, and how do 1 go about it?

James Braun Webster Groves, Mo.

The B-8HC spark plugs are too cold for your machine under normal circumstances. The B77HC is the correct plug; however, until you have solved the fouling problems, I would suggest that you use a B-7HZ. Your trouble is most likely caused by incorrect carburetion or a faulty or incorrectly adjusted oil pump. From the condition of the offending spark plug it should be obvious to an experienced mechanic which one of the two systems is at fault.

It is impossible for me, within the medium of this letter, to solve your problem as it would be necessary for me to visually inspect the machine. If you are not capable of making this determination yourself, all I can recommend is that you find a competent Yamaha mechanic. When the problem has been solved, or if another owner has experienced a similar problem with this model, I would very much like to know the cause. (No, I do not own a YDS3C with the same trouble.)

PARTS CLEANING

I have a 1961 Velocette Scrambler and am in the process of rebuilding it. Everything is coming along fine except one thing. The person who had this machine before me did a sloppy job of putting some heat-resistant paint of some kind on the barrel, head and valve cover. 1 have been trying to find a way to get these parts down to bare metal. 1 would appreciate it if you could suggest anything. I enjoy your magazine very much. It is quite informative.

Steve Cattrell Canoga Park, Calif.

To obtain the best results it will be necessary to dismantle the engine and have the individual components vapor blasted with a non-abrasive substance. There are a variety of substances to choose from, one of the most suitable for engine components being ground walnut shells. This substance is also very good for cleaning certain internal parts without leaving embedded abrasive deposits. A good example of this would be the removal of carbon from the piston crown and ring land areas.

In any case, do not use sand blasting as a medium for cleaning engine parts.

TUNED PIPES

Throughout a stack of CYCLE WORLD back issues 1 have come across quite a few articles and references in regard to twostroke expansion chamber tuned exhaust systems.

1 gather you are an ardent two-stroke fan and quite lettered on the subject.

1 have a problem and need some help if you have the time. My problem is this: 1 have a 1965 YDS-3 Yamaha 1 am drag(Continued on page 36) ging. The engine is stock and the bike is in full trim. 1 turn in the 15.80s. My best to date is 15.81 seconds (last week). I feel 1 am losing or missing a lot of engine power at the exhaust.

Do you know of an expansion chamber that will replace my exhaust system and give me the benefit of a tuned system? Noise is no problem, as I won’t be on the street. I can do construction if 1 can get the dimensions. Is it possible you have this information on hand, or know of someone who does?

Edward A. Jones Rippon, California

Sorry, we do not have the dimensions of an exhaust system as requested by you. We do, however, suggest that you use a system of the expansion chamber type. If you wish to continue with the stock engine, a suitable exhaust system could be evolved by applying the principles of design outlined by Gordon Jennings in the CYCLE WORLD Technical Manual.

The YDS-3 can be extensively tuned by employing the wide range of racing parts that have been made available by Yamaha. We suggest that you contact your nearest dealer or write direct to Yamaha concerning these parts and tuning data.

CHEAP RACING

I read your articles and advice on shop modifications of production bikes with great interest, but most of them are too far out (too complete, really) for me to make use of. With a limited budget and a still-growing appetite for speed, 1 cannot consider putting $200 into a small displacement, $400 machine in order to get it to go 100.

Why not do an article on the step-bystep elimination of “weakest links” in the small two strokers with some attention to economy? If, for instance, you were to suggest a couple of minor mods for my Yamaha Y A-6 for starters, 1 would probably want to make the next changes your article suggested about as soon as the head was back on and a few tests made.

Your average reader must be a guy with few cubes and fewer dollars who would tinker plenty if you could show him an easy, gradual path to follow. How about nursing us along to bigger things?

John Irwin

Cleveland, Ohio

Tuning a two-stroke is not a simple matter and any individual modification will invariably adversely affect the complete cycle of events. In other words, just increasing the compression ratio or fitting a large carburetor will, in most cases, result in a decrease in horsepower. Changing one thing only will upset a carefully balanced system. Yamaha advertises complete range of race parts for the Y A-6 and can also supply a speed manual that covers modifications to this model. They strongly advise that all the modifications must be carried out at one time to ensure good results.

These remarks do not apply so strictly to the four-stroke engine, and mild individual modifications can be made with good results.

Tuning for speed is expensive, and to get your machine to even approach 100 mph (in full road racing trim) would cost far in excess of $200.

CHAIN CARE

I have spoken to many motorcyclists and it has been my experience that few have not heard of a mystical, magical potion for motorcycles. This potion I’m speaking of is supposed to be a special witches’ brew in which the chain and cables of a bike can be boiled to gain everlasting lubrication. I’ve heard the same story from just about everyone, and I’m wondering if such a panacea of lubrication exists. To date there are three points about this solution upon which everyone agrees:

1. It contains graphite.

2. It must be boiling hot before the chain and cables can be soaked in it.

3. It ruins the pot in which it is cooked.

Disagreement occurs as to its effectiveness. Some say it will keep the chain lubricated for six months, others say a year, and some say indefinitely. What 1 would like to know is does such a concoction exist and could you give me the recipe for it if it does exist?

(Continued on page 38)

Ed Morkunas

Urbana, Illinois

It is considered good practice to boil the drive chains in a suitable lubricant to obtain good penetration to all the working surfaces. This method is of the most value when it is applied to the rear chain. In addition to providing good penetration, the boiling action assists because of agitation, in the removal of dirt and old lubricant from the important pin and roller bearing surfaces.

A high melting point bearing grease provides a good base material. A solution containing graphite or molybdenum disulfide is better still. First, remove all surface dirt from the chain with a wire brush. Put sufficient lubricant in a suitable container that will allow the chain to be fully submerged. Place the chain in the container and heat it to the boiling point. Let it boil from five to ten minutes; then remove the chain and hang it up by one end to allow the excess lubricant to drain off. With an old chain that is in poor condition, it may be necessary to boil for a longer period. It is not necessary for the chain to be dropped into the already boiling oil.

Also, be careful. Remember that boiling grease is very inflammable and we don’t want Mom’s kitchen destroyed, now do we?

Unfortunately, the lubrication does not last indefinitely. The duration of effective lubrication will depend primarily on the operating conditions to which the motorcycle is subjected.

CARB QUERY

I have a fairly technical decision to make concerning my Honda 250 Hawk. In a recent accident, a bunch of the cooling fins were broken off the cylinder head. I have available to me a 305 head and carburetors. My problem is whether to use my 22mm carbs with the 305 head, or use the 26mm carbs. Since the ports in the 305 are initially the same size as the 305 carbs, l figure that the intake gas flow would be smoother with the 26mm carbs, but I tend to shy away from them because of the absence of a power fuel system in them, since I don’t know through what rpm range this system effectively influences mixture control, and my megaphones “goof” stuff up enough already.

Also, 1 am afraid that, with the larger ports in the 305 head, intake gas velocity would not reach maximum torque or power speeds until more rpm were developed using either set of carbs since my displacement is smaller, and therefore maximum torque or power would not come in until the engine turned faster than before, and it had lousy enough low rpm pulling characteristics. Possibly adding the larger carburetors would only multiply this situation, unless the additional quantity of combustible mixture introduced would cause sufficient rise in port gas velocity or give enough boost to combustion that ibwould overcome the (theoretical) “volumetric deficiency” created by larger ports and carb diameter.

(Continued on page 40)

On the other hand, the valve seats in the 250 and 305 are the same size. This indicates to me that intake gas would be traveling at a very similar speed at the valve seat (where it counts) in both heads, and that, trying to cram more fuel mixture through the same size valve with the larger carburetors would increase gas velocity at the valve inlet and drop the number of revolutions necessary to obtain maximum torque and power, even though port velocity may be lower than in the usual 250.

At any rate, I would appreciate your opinion on what I should do. In conclusion, I would like to thank you for your Technical Manual. It has provided me with many stimulating moments. I can never wait until I have enough time to read or re-read one of the articles, although 1 do wish you had included more of the formulas and functions you mention. That stuff really excites me.

Steve Skale San Mateo, Calif.

The 26mm carburetors will provide a small increase in horsepower at high engine speed because of a slight increase in volumetric efficiency. The increase in carburetor size will, however, effect low speed torque and make the machine less tractable. In fact, throttle control and carburetion would be more sensitive at low speed. Using smaller carburetors and therefore having a sudden change in the cross-section of the intake port may sometimes have an adverse effect on carburetion; but this is unlikely when using one carburetor per cylinder because of the relatively large pulsations in the system.

The absence of power jets in the 26mm carburetors will not cause any problems. Whichever carburetors you use, you will have to go through the procedure of checking and rejetting for correct mixture.

The main disadvantage found in using the 305 cylinder heads will be caused by the difference in combustion chamber configuration. The 305 has a larger chamber and will be partially shrouded by the smaller 250 cylinder bore diameter. You will have a lower compression ratio with the 305 head on a 250.

FLOAT FACTS

I saw the letter from William D. Harter in the September issue in which he asks about a problem he and two friends are having with their 1965 CB-I60s. 1 have a 1966 CB-160 with about 7,500 miles, and was having the same problem. It’s had two 1,000-mile checks, and a complete new ignition system, with no help. But it’s cured now. The mechanic found that the float levels in the carbs were off, adjusted them and no more trouble.

Roy B. Scherer Richmond, Va.

Thanks for your letter, Roy. Your remarks may be of some assistance to other CB-160 owners having trouble with their engines dying at high speed. A low float chamber fuel level could certainly cause similar symptoms.