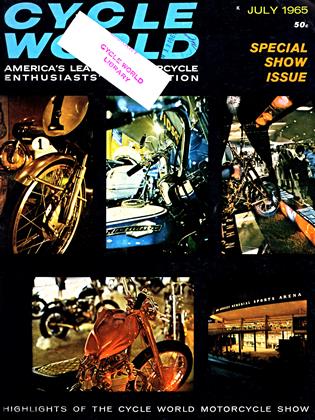

THERE ARE MANY PEOPLE who will delight in telling you that "ol' Harley-Davidson is goin' down the drain." Well it ain't. Furthermore, this kind of talk has probably been going on for the last 62 years, all the way back to 1903 when Bill Harley and Arthur and Walter Davidson combined their resources and brain power to produce their first motorcycle.

The total output in 1903 was one machine, and this was increased to eight in 1904 which shows a cautious but steady growth for the company. However, by the end of 1906, another 50 machines had been built, ana it was necessary to hire five assistants to keep pace with production. Since these early days, the company has made steady progress until, during the course of a recent interview the current president, William H. Davidson, said that his sales target for the 1965 fiscal year is $32 million.

Over the years, the company has always remained a family affair. Both the Harleys and the Davidsons are prolific groups, and the organization is thick with them. However, there seems to be no feuding or fighting between them and, at present, the third generation is just beginning to make itself felt. Young Bill Davidson, son of the president, has recently been appointed Director of Styling after spending several years working for Brookes Stevens, the well known Milwaukee industrial designer, and other Harleys and Davidsons are being groomed for managerial posts.

Although control of the company has always remained within the two families, there are about 300 stock holders, and many of them are either Harley-Davidson dealers or employees of the company. Perhaps because it is a family affair, there is an excellent record of employment and dealer relations, as evidenced by the surprisingly large number of old employees. My guide through the factory was Jim Coates, who has worked there man and boy for the last 48 years.

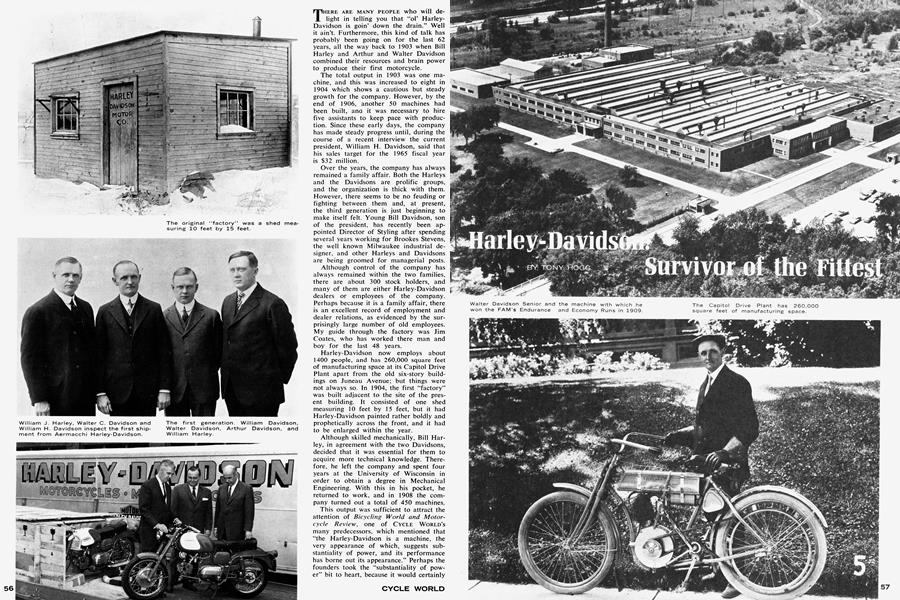

Harley-Davidson now employs about 1400 people, and has 260,000 square feet of manufacturing space at its Capitol Drive Plant apart from the old six-story buildings on Juneau Avenue; but things were not always so. In 1904, the first "factory" was built adjacent to the site of the present building. It consisted of one shed measuring 10 feet by 15 feet, but it had Harley-Davidson painted rather boldly and prophetically across the front, and it had to be enlarged within the year.

Although skilled mechanically, Bill Harley, in agreement with the two Davidsons, decided that it was essential for them to acquire more technical knowledge. Therefore, he left the company and spent four years at the University of Wisconsin in order to obtain a degree in Mechanical Engineering. With this in his pocket, he returned to work, and in 1908 the company turned out a total of 450 machines.

This output was sufficient to attract the attention of Bicycling World and Motorcycle Review, one of CYCLE WORLD'S many predecessors, which mentioned that "the Harley-Davidson is a machine, the very appearance of which, suggests substantiality of power, and its performance has borne out its appearance." Perhaps the founders took the "substantiality of power" bit to heart, because it would certainly seem to apply to the larger machines in the range today.

Harley-Davidson. Survivor of the Fittest

TONY HOGG

From the very earliest days, the Indian Motorcycle Company of Springfield, Mass. provided the biggest opposition to HarleyDavidson, and this situation continued until the end of World War I when HarleyDavidson established itself as America's biggest motorcycle manufacturer.

With one eye on Springfield, Mass., it was decided in 1909 that the HarleyDavidson must prove itself in open competition. The big event of the year was the FAM (predecessor of the AMA) Endurance Run in Catskill, New York. Walter Davidson Sr. entered for the two day event and won the diamond medal awarded for first place. Not only did he win this event, but a week later he won the FAM's Economy Run by covering a distance of 50 miles on one quart and one ounce of gasoline.

This exhibition of stamina combined with economy drew the publicity it deserved, and it did a lot to establish HarleyDavidson as a power in the industry. Progress was swift from then on with production rising to 3168 in 1910, and in 1912 a phenomenal 10,000 machines were built by 1000 employees in a factory covering 185,000 feet.

All of the very early motorcycles were strongly influenced by current bicycle design, and were nothing much more than motorized bicycles. However, HarleyDavidson was one of the first manufacturers to realize that the motorized bicycle image was a poor one, and that what the public wanted was a powerful, rugged, and reliable two-wheeler capable of long distance touring over the roads of that day.

In an attempt to fill this demand, the first of the long line of big V-twins was introduced in 1909, and the superior power and flexibility it offered were immediately apparent. A further improvement in power was obtained from the use of positively opened intake valves in 1911, which permitted considerably higher engine revolutions to be used.

To improve the reliability of the machines, magneto ignition was used from 1909 in place of the battery and coil which were very unreliable in those days.

In 1915 an ingenious gear-driven magnetogenerator combination was offered. The generator charged a storage battery so that lighting was available when the engine was dead, and the magneto provided an independent ignition circuit so that the engine could be started with a flat battery. However, the army model, of which some 20,000 were supplied, was equipped with carbide lighting presumably because of the problems associated with batteries.

To insure maximum rider comfort, what was known as the Ful-Floteing Seat was introduced in 1912. This arrangement had two springs under compression inside the vertical frame tube, and it is basically the same as the seat used today. In 1914, footboards appeared for the first time, and they seem to have remained long after everyone else thought they were archaic.

Many people feel that Harley-Davidson is far too conservative in its outlook, and has been for years. However, William Davidson's feeling is that it is better to be right than to be first, and perhaps the survival and present strength of the company after the demise of all the other American manufacturers is due in part to the pursual of this policy.

Recalling a happy year in the late 40s spent working as an engineer for the company, John R. Bond, who is now the publisher of Road & Track, says that he was surprised at the amount of latitude he was allowed in designing and developing new ideas, but disappointed that none of them ever seemed to get to the production line.

A look through the company's files corroborates this statement, because it would appear that at one time or another HarleyDavidson has built prototypes of every conceivable kind of vehicle that would propel itself on two or three wheels.

Although the company's museum is dominated by the various big twins produced over the years, there are a number of other interesting machines such as the 42 cu. in. flat twin with its cylinders facing fore and aft of 1919. Then there is the 1926 21 cu. in. single which was offered in either side valve or overhead valve form. This was followed in 1929 by a larger side valve single of 30 cu. in.

Another interesting machine is the 42-XA model. Reputedly, 1000 of these were built for the army during the second World War, and they look like a fair replica of a BMW. The engine is a side valve flat twin mounted transversely, and shaft drive is employed to the rear wheel. However, this machine was a small part of Harley-Davidson's war production, because the company produced 88,000 of the conventional 45 cu. in. twins in various forms for use by the American and allied services.

Unfortunately, the various competition models are lacking in the museum but, nevertheless, Harley-Davidson has always been and continues to be strong in competition. Since the reintroduction of road racing in America, the company has been active in this branch of the sport. Dick O'Brien, Chief Racing Engineer, admits to a tremendous enthusiasm for the exotic foreign racing machinery, but feels that the AMA rules are more suited to American racing because they give everyone a better chance. (Some other time. Ed.)

Harley-Davidson has often been accused of manipulating the AMA. This is a difficult question, and William H. Davidson points out that his company helped to keep the AMA alive for a long time when H-D was the only effective manufacturer in the country. Furthermore, this support goes right back to as early as 1914 when Harley-Davidson riders such as Otto Walker and "Red" Parkhurst were burning up the tracks at Dodge City, Venice and Bakersfield.

With regard to the 45 cu. in. side valve class, he reminds you that this was introduced decades ago specifically to provide competition between the 45 cu. in. HarleyDavidsons and the 45 cu. in. Indians. As he says, nobody in their right mind would develop one of these machines for racing, but they were the only things available to the amateur at that time. When the imports appeared, it seemed logical to permit 500cc overhead valve machines to run against them, provided they were basically road machines. Despite a considerable amount of arguing, this arrangement seems to have been a good compromise.

A visit to Harley-Davidson is something of an eye-opener because the factory is an incredible mixture of ancient and modern. At Capitol Drive, all operations requiring heavy machinery are carried out. Starting at the press shop one can watch various sheet metal parts being formed. In the next section pistons are machined and cams ground from rough castings, and one can see the machining, dynamic balancing, assembly, and inspection of flywheel assemblies.

Progressing through the plant, there is a long row of automatic machines that churn out thousands of the small but complicated parts requiring multiple machining operations. Then there is the gear cutting department, heat treating shop, and other interesting areas.

All the parts produced at Capitol Drive are trucked over to the Juneau plant where they are carried up to the correct floor in freight elevators. Ascending in one of these elevators, one finds that suddenly it is 1912 again because Juneau and Capitol Drive are in direct contrast.

Entering Juneau one finds the offices on the first floor together with a very modern looking computer room. But upstairs there are five more floors crammed with poky and dirty little areas where one finds elderly employees carrying out incredibly laborious hand operations.

Eventually, all the products of Juneau and Capitol Drive are consolidated at the production line on the ground floor where the assembly line is located. Here one realizes how much of a custom job the big twin is, because each machine is assembled according to a specification sheet showing the color combination, the accessories, and also the name of the dealer to whom it is going. Harley-Davidson builds to dealers' orders only, preferring to have machines on the showroom floor rather than locked up in a warehouse where they cannot be seen or bought by the public.

Until the late twenties, all machines were finished in a smart olive green, but then the demand for brighter and brighter colors with more chrome began to make itself felt. Until now, to the Europeanoriented eye, the Electra-Glide assembly line looks like a herd of elephants being decked out with Christmas tree lights. Ah well, perhaps I would think differently if mother had been a Motor Maid.

Although no specific output figures are available, it is evident that the big twin is by far the most popular machine, so that Harley-Davidson is in the position of having created a monster and also created a demand for it, and can only fill that demand. One of the results is that American motorcycling is unfortunately divided between the hard core Harley-Davidson riders and those who favor the smaller imports, with shouts of "hawg," "Limey," and "Japanese junk" being tossed back and forth between the factions.

At $2000 or more the Electra-Glide is not cheap. The sheer bulk of the materials used must account in part for the price, but another factor is that the company has been obliged in the past, and seems to have gotten into the habit of making every part of the machine itself. How necessary this is must be a matter for conjecture, but the fact remains that with the exception of foundry work, rubber and plastic parts, ball and roller bearings, and a few minor items, the whole machine is made by the company.

European manufacturers who have toured the plant are amazed at this state of affairs. They are accustomed, when they want an item such as fuel tanks, to getting on the telephone to their tank manufacturer and ordering some. Harley-Davidson makes its own generators, some of its own ignition coils and has even made its own spark plugs.

In explanation, William Davidson says that they have had some very sad experiences with outside suppliers in days gone by. Furthermore, he points out that there is no motorcycle industry in America except for his company, and there are no manufacturers, such as Joseph Lucas in England, which can supply a big national industry with electrical equipment designed and built specifically for motorcycle use.

One suspects that by buying components outside, the cost of the machine could be cut, because, not only is Milwaukee famous for its beer, but also for its countless machine shops that can make almost anything, and motorcycle components would not present any peculiar problems to them. However, Harley-Davidson has an immense pride in its products and feels that it can control the product better by making everything itself, which is undoubtedly true. Furthermore, discontinuing a particular manufacturing process would mean laying off employees, and the company has a strong sense of loyalty to its people.

(Continued on page 102)

Although Harley-Davidson has a long history of steady development and progress, it has also had its ups and downs. One of the downs occurred in September 1949 when the directors woke up one morning to find that the pound sterling had been devalued from $4.00 to $2.80. Until that time, the selling price of the Harley-Davidson and the English imports was about on a par, but devaluation gave the imports a clear cut lead.

The company responded by taking the matter to the tariff commission and requesting a special rate of duty on the imported machines. After much discussion, this request was turned down on the grounds that Harley-Davidson had not been hurt, so a decision was made to cut costs as far as possible and to fight the imports on their own ground.

In this connection, Walter Davidson who is Vice President in charge of sales, seems to have a legitimate gripe. He points out that all motorcycle producing countries protect themselves with high tariff barriers, but America allows foreign products to be imported at a purely nominal rate of duty. This gives Harley-Davidson the maximum amount of competition at home, but cuts off its outlets overseas. In fact, there is some export business, but it is confined to military machines. An attempt was made to reintroduce the pleasure bikes to England, but this was killed stone dead by the Socialist government's introduction of an additional 15% tax over and above existing tariff barriers.

(We'll point out here that in this regard, one reason for the lack of a large import tariff or duty in this country is simply that our exports far exceed our imports. In most countries, particularly Great Britain, the opposite is the case, and by an extremely wide margin. Ed.)

In order to gain access to the Common Market, and also to obtain additional manufacturing facilities, in 1960 HarleyDavidson formed Aermacchi Harley-Davidson in Italy in conjunction with Aeronautica Macchi, an Italian producer of aircraft and motorcycles. This venture introduced the 250cc Sprint models, and has enabled the company to offer a range of machines from 50cc to 1200cc.

Looking into the future, one can expect Harley-Davidson to continue offering its wide range of motorcycles, and probably to diversify even more into the area of golf carts and other related machines. The sales pitch is currently being revamped to include direct mailing to 600,000 riders, and the advertising program now includes the national magazines rather than just the specialized ones.

After spending two days at the factory, one comes away surprised and suitably impressed by the whole organization, and far less inclined to shout "hawg" the next time a big Harley-Davidson passes by. •