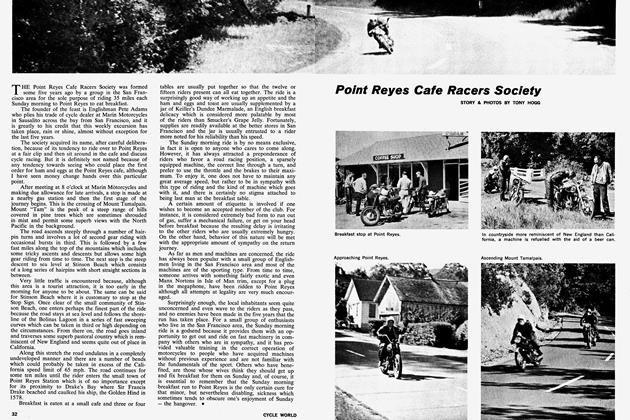

THE NORTON MANX

TONY HOGG

IN 1927 WALTER MOORE, who was chief designer for the Norton Motorcycle Co. of Bracebridge St., Birmingham, England, drew up a racing machine which was designated the CS-1. By a long process of development, this machine was destined to keep the name of Norton in the forefront of motorcycle racing until the present day, and will probably continue to do so for several years to come. This may seem remarkable in an era when one can buy a competition sports car in January and discover that it is out of date by June but, owing to circumstances peculiar to motorcycle racing and some fairly astute engineering by Norton, it is nevertheless true.

Moore’s design was a 490cc single-cyl. engine of 79 mm by 100 mm, with overhead valves operated by a single cam and bevel gears. Also in 1927, Norton made two decisions which have been very largely responsible for the stability of its racing motorcycle business: the company made replicas of this machine available for sale at a realistic price, and hired a hawknosed, practical Irishman named Joe Craig to take charge of both engineering development and management of the factory racing team. Craig held these positions until his retirement in 1955, which was soon followed by his unfortunate death in a road actident in Austria in 1957.

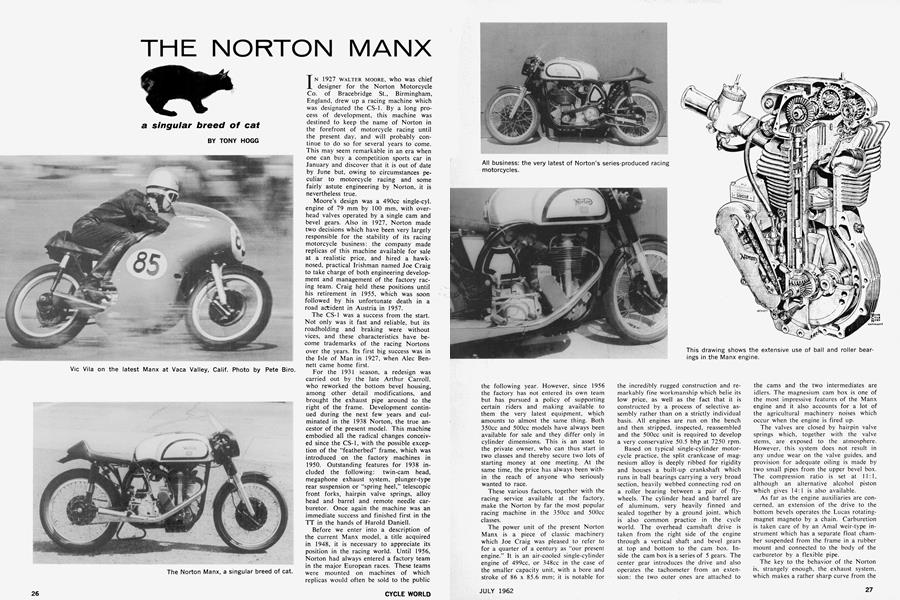

The CS-1 was a success from the start. Not only was it fast and reliable, but its roadholding and braking were without vices, and these characteristics have become trademarks of the racing Nortons over the years. Its first big success was in the Isle of Man in 1927, when Alec Bennett came home first.

For the 1931 season, a redesign was carried out by the late Arthur Carroll, who reworked the bottom bevel housing, among other detail modifications, and brought the exhaust pipe around to the right of the frame. Development continued during the next few years and culminated in the 1938 Norton, the true ancestor of the present model. This machine embodied all the radical changes conceived since the CS-1, with the possible exception of the “featherbed” frame, which was introduced on the factory machines in 1950. Outstanding features for 1938 included the following: twin-cam head,

megaphone exhaust system, plunger-type rear suspension or “spring heel,” telescopic front forks, hairpin valve springs, alloy head and barrel and remote needle carburetor. Once again the machine was an immediate success and finished first in the TT in the hands of Harold Daniell.

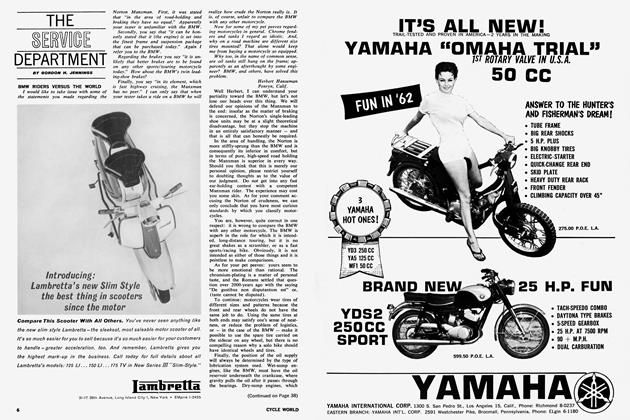

Before we enter into a description of the current Manx model, a title acquired in 1948, it is necessary to appreciate its position in the racing world. Until 1956, Norton had always entered a factory team in the major European races. These teams were mounted on machines of which replicas would often be sold to the public the following year. However, since 1956 the factory has not entered its own team but has pursued a policy of supporting certain riders and making available to them the very latest equipment, which amounts to almost the same thing. Both 350cc and 500cc models have always been available for sale and they differ only in cylinder dimensions. This is an asset to the private owner, who can thus start in two classes and thereby secure two lots of starting money at one meeting. At the same time, the price has always been within the reach of anyone who seriously wanted to race.

These various factors, together with the racing service available at the factory, make the Norton by far the most popular racing machine in the 350cc and 500cc classes.

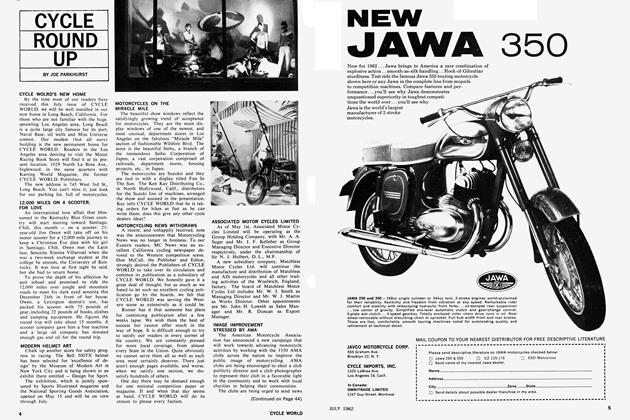

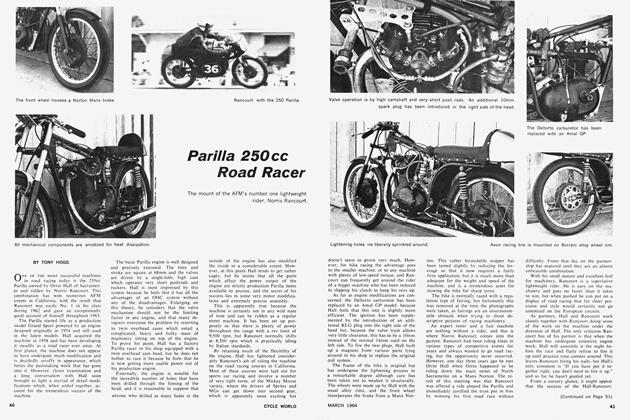

The power unit of the present Norton Manx is a piece of classic machinery which Joe Craig was pleased to refer to for a quarter of a century as “our present engine.” It is an air-cooled single-cylinder engine of 499cc, or 348cc in the case of the smaller capacity unit, with a bore and stroke of 86 x 85.6 mm; it is notable for the incredibly rugged construction and remarkably fine workmanship which belie its low price, as well as the fact that it is constructed by a process of selective assembly rather than on a strictly individual basis. All engines are run on the bench and then stripped, inspected, reassembled and the 500cc unit is required to develop a very conservative 50.5 bhp at 7250 rpm.

Based on typical single-cylinder motorcycle practice, the split crankcase of magnesium alloy is deeply ribbed for rigidity and houses a built-up crankshaft which runs in ball bearings carrying a very broad section, heavily webbed connecting rod on a roller bearing between a pair of flywheels. The cylinder head and barrel are of aluminum, very heavily finned and sealed together by a ground joint, which is' also common practice in the cycle world. The overhead camshaft drive is taken from the right side of the engine through a vertical shaft and bevel gears at top and bottom to the cam box. Inside the cam box is a series of 5 gears. The center gear introduces the drive and also operates the tachometer from an extension: the two outer ones are attached to the cams and the two intermediates are idlers. The magnesium cam box is one of the most impressive features of the Manx engine and it also accounts for a lot of the agricultural machinery noises which occur when the engine is fired up.

The valves are closed by hairpin valve springs which, together with the valve stems, are exposed to the atmosphere. However, this system does not result in any undue wear on the valve guides, and provision for adequate oiling is made by two small pipes from the upper bevel box. The compression ratio is set at 11:1, although an alternative alcohol piston which gives 14:1 is also available.

As far as the engine auxiliaries are concerned, an extension of the drive to the bottom bevels operates the Lucas rotatingmagnet magneto by a chain. Carburetion is taken care of by an Amal weir-type instrument which has a separate float chamber suspended from the frame in a rubber mount and connected to the body of the carburetor by a flexible pipe.

The key to the behavior of the Norton is, strangely enough, the exhaust system, which makes a rather sharp curve from the exhaust port, runs alongside the crankcase and ends up in a megaphone behind the footrest. This megaphone is one of Joe Craig’s brighter ideas and it is coupled with a severe valve overlap to give a kind of supercharger effect to the engine. The theory is that the exhaust gases go through a period of controlled expansion in the megaphone that creates suction in the exhaust system and draws in the mixture through the intake valve, because both intake and exhaust valves are open simultaneously at the end of the exhaust stroke. The one disadvantage of this system is that the power curve of the engine starts at about 35 bhp at 4200 rpm but goes no lower, simply because there isn’t any usable power whatsoever at lower revolutions. This presents a problem to any rider who is unused to this type of engine, because he is obliged to keep the engine above the speed at which it "comes on the megaphone” and below its peak of about 7200 rpm.

In conjunction with this exhaust system is, of necessity, a very close ratio gearbox, which, when coupled to a large engine sprocket, permits a maximum of 71 mph in 1st, 93 mph in 2nd, 115 mph in 3rd and a high gear speed depending on the limitations of the road and the rider’s nervous system. Characteristically, the Norton is easily over-revved in 1st, less easily in 2nd, infrequently in 3rd and the less experienced riders tend to shift into high far too early. Having tried the machinery, I feel that one tends to shift into high too early simply because the thing is going too cotton-pickin’ fast.

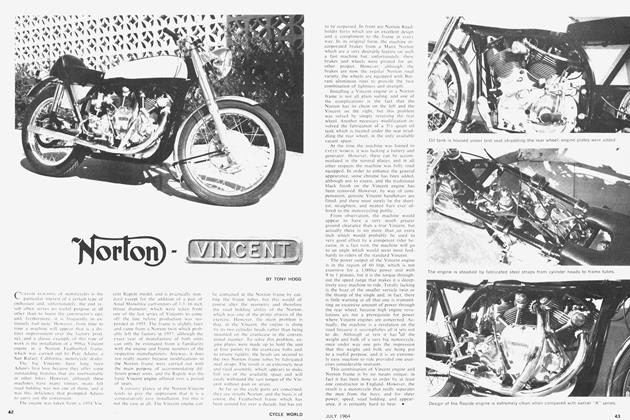

The cycle parts are based on the “featherbed” frame, which is a double loop of welded tube of extreme rigidity. The front forks are of the conventional telescopic-type, and the rear suspension is pivoted just behind the transmission, and employs two hydraulically damped shock units which can be set in three positions, depending on the road surface and the weight of the rider. Before 1936 no provision was made for rear suspension at all, and in this year a plunger-type “spring heel” was introduced. Although its movement was limited, it vastly improved roadholding and, furthermore, enabled the older riders with all their track craft and experience to carry on racing past the time when their kidneys would no longer stand the pounding of the rigid-frame machines.

Light alloy is used for the wheel rims, the hubs and the brake shoes, and the front brake is of the two-leading-shoe variety. Tire sizes are 3.00-19 at the front and 3.50-19 at the rear, and are run at about 21 and 24 lb, respectively.

The English automobile magazines often use the descriptive phrase, “When one assumes the driving position, all the controls come easily to hand,” but this is not at all true of the Norton. One sits far back on the seat, which is very hard indeed, and has a cutaway in front for the oil filler cap and a pad at the back which permits a certain amount of fore and aft body movement so that one can assume a low crouching position to reduce drag at high speed. The footrests are far back and high to avoid grounding in the turns, and the short, stubby handlebars are low and well forward. No provision is made for starting the engine other than by pushing the machine—this is normal racing practice, of course.

Once the engine is started, oil flow should be checked by looking in the filler cap to see if the return flow is visible, because there is no oil gauge. A long warmup period is usually necessary because of the heavy finning, and this sometimes presents problems in the English climate, where it is not uncommon to see Norton engines wrapped in blankets. After the warm-up period, 1st gear can be engaged with the lever at the right foot and, by accelerating the engine to about 5000 rpm, which is over the point where the megaphone takes effect, the clutch can be gradually eased in as the bike starts to move. Assuming we are using the big engine sprocket referred to before, the clutch must be slipped until the machine is running about 45 mph, when the megaphone takes effect and you suddenly find you have about 35 bhp to play with. The machine will now take off like a rocket and can easily be over-revved unless you shift into 2nd at about 70 mph. This will take you through to over 90 mph, when 3rd can be engaged. If you haven’t chickened out by now, you can catch high at 115 mph, but it must always be remembered that if you shift up too soon you will drop the revs below 4200 rpm, get off the megaphone, and lose all the power, which can only be regained by slipping the clutch or shifting down again. A very critical selection of ratios, therefore, is required if the best use is to be made of the power available.

Before one can attempt to achieve anything with the Norton, it is essential to serve a long apprenticeship on large-capacity, fast road machines. With this experience, it is not too difficult to master the much higher speed, the very close ratios and the megaphone problem. In fact, the Norton will then emerge as a deceptively easy machine to ride because of its superb handling qualities, which in racing permits an experienced rider to leave his braking a shade later, to enter a turn later at a steeper angle and come out earlier using more power. In cycle racing, braking must be carried out with the machine in a straight line, and when coming out of a turn with the machine laid over, the power must be fed carefully to the rear wheels, as too much torque will put you on your beanie without any warning at all.

European racing has been dominated for the last few years by the Italian multicylinder machines, which have been strictly factory entries and not available for sale at any price. Nortons have frequently given these machines a very good run for their money, and sometimes even beaten them. One reason is that the Norton has a very positive feel to it, and an experienced rider can feel each beat of the engine through the seat of his pants, and need only read his tachometer when he is intentionally over-revving, or when sorting out his gear ratios in practice. On the other hand, the Italian “fire engines” come on screaming with a great rush of power which requires a genius to transmit successfully to the rear wheel, and it is very difficult for a rider to make the transition from a single to a multi-cylinder machine.

In a recent conversation with World Champion John Surtees, I asked him about the maximum speeds of the MV Agusta 4 and the Norton on the Masta straight at Spa, which, with its fast-curving entry and slight downgrade, is one of the fastest sections of any circuit in Europe. Surprisingly enough, he said that on an Agusta he would be reaching slightly 160 mph and a good hot Norton would not be far behind at about 154 mph.

Of course, even if you hand over your $1599 and take possession of a new Manx, you won’t be doing any 154 mph on the Masta straight, because this sort of speed is attained only by those machines which have either been specially prepared by the factory for a favored rider or been completely reworked by someone dedicated to the preparation of Nortons. In England there are several people who have made this their life’s work, notably Francis Beart and Steve Lancefield, who will accept your Norton with considerable disdain, as though it were nothing more than a set of rough castings, and proceed to build it as they think it should be built. The results are usually sensational but expensive and, of course it is all a sheer waste of time if you aren’t able to use to good effect the 50 bhp which was there in the first place.

In its time, the Norton engine has probably undergone more modification and experimentation by enthusiasts than any other power unit, and these modifications seem to set fashions. I remember when twin-plug heads were strictly de ri geur, and then there was a period when additional finning had to be added to the already heavily finned head and barrel, so that the engine ended up looking like a medii am sized garbage can. On the other har id, some people will either discard the fran ae entirely and use a frame of t heir ow 'n construction or, alternatively, discard th e engine and put in some other type o f power unit. But whatever you do with it , the Norton is a remarkable machine for the exercise of mechanical ingenuity, and even to keep it in racing trim according to factory specifications demands quite a lot of accurate hand work of a rather specialized nature.

Over the years, Nortons have encountered opposition from a wide variety of different manufacturers. Before the war there were the supercharged BMW twins, the V twin Husqvarna, the 4-cyl. supercharged AJS, and the Velocette, to name a few, and latterly there have been the Italian teams such as MV Agusta, MotoGuzzi and Güera, with BMW and the AJS “Porcupine” periodically in contention. In order to remain competitive Norton has sometimes been tempted to discard its archaic old single, and in 1953 experimented on a water-cooled four which was never completed. In 1954, Norton built a rotary valve head for the Manx engine and recently has been running a desmodromic version.

However, none of these ideas has yet reached the customers, and although there are wild rumors each year of a radically new Norton, when it appears, it is always the same basic machine with some detail refinements: nothing sensational, a little more power, a little more speed, and a little more reliability.