[TECHNICALITIES]

GORDON H. JENNINGS

ONE OF THE least-understood aspects of engine design is the manner in which a piston ring does what it does. Most people seem to have the idea that the ring's sealing action is provided by natural radial tension, which holds the flat surface of the ring pressed out against the cylinder bore. Actually, while it is true that some spring tension is required to make the ring function, it will not provide a seal using only the pressure supplied when it is compressed and slipped into the cylinder. Think about it for a moment and you will see that this is really quite obvious. You can force the ring into its groove in the piston with your fingers; those same fingers would never be able to hold the sort of gas pressures we have in the cylinder shortly after the moment of ignition.

And just what is it that holds all that gas pressure? The answer: gas pressure. As pressure builds in the cylinder, it is applied above the piston ring, which holds the ring against the bottom of the ring groove. As there is clearance between the ring and its groove, the pressure is exerted over the entire top of the ring and even back behind it, which provides a pressure that forces the ring outward and hard against the cylinder walls. Thus, the sealing force is always proportioned according to gas pressure in the cylinder.

There are things that will upset this sealing process. Hard-carbon or varnish formations after extended service will stop free movement of the ring, and that will result in excessive blow-by. Incidentally, this provides a good reason for using detergent oils, which will keep pistons clean and the rings free. Then too, after long service the ring grooves may become a bit battered, and if the floor of the ring groove loses its flatness, much of the seal at the lower surface of the ring will be lost. A battered ring groove may also allow the ring to twist, and when this occurs the edge of the ring, which contacts the cylinder wall, will become rounded and some sealing effectiveness destroyed.

A two-stroke engine's piston rings must survive particularly unhealthy living conditions. The combination of high piston temperatures and excessive oil in the upper cylinder area creates especially severe varnishing. This, in turn, is made all the more pernicious by the fact that the ring is not free to rotate. In all of the twostrokes we will encounter in the motorcycle field, the ring grooves are fitted with a pin to prevent ring rotation. This is necessary because if the rings rotated around until the gap reached a port, the end of the ring would spring out into the port and become trapped, with breakage occurring as the piston moved back toward top center.

In a four-stroke engine, where the rings are free, ring rotation provides a measure of scrubbing in the ring grooves and helps to keep them clean. And those rings do rotate, unless mechanically prevented from doing so. In all engines, the crankpin will have its axis at a slight angle relative to the mainshafts. If we assume this angle to be even a quarter-degree, then the total angular displacement of the crankpin relative to the mainshaft is one half degree — measured between top and bottom centers. This angular displacement will, of course, be transmitted to the piston, and from the piston to the piston ring. Actually though, while the piston itself will swash back and forth, the fact that the ring is bearing hard against its groove at some points in its travel and virtually floating free at others will convert the piston's swashing motion into pure rotation at the ring. All of this means that an unpinned ring will rotate, and it will tend to scrub varnish away and keep itself moving free. And, it also means that spacing the ring's end gaps 180-degrees apart when installing the piston is largely futile. Random rotation will very likely change all that within a few minutes of running. As I recall, a research report on the subject of ring rotation stated that the ratio of rotation, for the ring relative to the crankshaft, was about 1:1000 at moderately high piston speeds. In other words, at 5000 rpm, the ring would be turning in its groove at the rate of 5 complete revolutions per minute.

(Continued on page 14)

So much for ring rotation; I will now acquaint you with the most destructive influence to which piston rings are subjected. Most of you will be aware, if only vaguely, that a piston is subjected to tremendous acceleration. It is not unusual to have mean piston speeds of 4000 ft/min, and yet this fast-moving piston must make two complete stops (top center, and at bottom center) in each complete crankshaft revolution. Loads during all this stopping and starting are very high. Indeed, in many engines the acceleration of the piston at high crank speeds may reach and even exceed, 100,000 ft/sec2 (the acceleration of gravity is 32 ft/sec2).

Now then, even when there is no piston failure, the loads applied by acceleration can have a disastrous effect on piston-ring performance. It has been explained that the ring gets its sealing pressure from gas pressure. The gases must hold the ring against the floor of the ring groove in addition to holding it out against the cylinder wall. Inertia, as the piston is being pulled to a stop at top center and accelerated back into motion on the down stroke, can overcome gas pressure above the ring and make the ring lift from the groove floor and move up against the top of the groove. When that occurs, pressure is lost behind the ring and it will be blown back into its groove, out of contact with the cylinder walls. This phenomenon is ring-float (more or less like valve-float) but is more commonly known (among engineers) as ring-flutter, the word "flutter" coming from a secondary effect of the original float. Following the original collapse of the ring back into its groove, there is a tendency for the ring to vibrate, radially, and this vibration, or flutter, will in many cases cause the ring to shatter if prolonged. Even when the ring does not actually break, the flutter does terrible things to the ring and its groove. And, of course, when inertia lifts the ring and starts the flutter, the ring's effectiveness as a seal is almost totally lost, which will produce a big blast of fire right down into the crankcase.

Ring-flutter can be controlled. You may have noticed that high-speed engines are usually fitted with quite thin compression rings. These, being light in relation to the surface they present to gas pressure from above, have a reduced tendency toward inertia-lifting. Unfortunately, there is a limit to thinning piston rings. Very thin rings wear rapidly and are rather fragile; too fragile, in fact, for the ordinary castiron that is otherwise such an excellent material for piston rings. Chrome-plated steel has been used successfully but steel rings are comparatively difficult and expensive to manufacture, and they are sometimes agonizingly slow to bed-in in a new engine. I might mention here that nodular cast-iron is probably the best all-around material for piston rings, with the long-wearing properties of ordinary cast-iron and the added advantage of ductility.

A few engines are fitted with the Dykes-pattern compression ring, which is if properly applied one of the best forms of piston ring extant. This ring was developed by a Paul Dykes, in England, growing out of findings from research into the phenomenon of ring flutter. Dykes overcame the ring float problem completely, with a ring having an L-shaped cross-section. The upper leg of the "L" bears against the cylinder wall, and gas pressure behind it makes it seal, just like a conventional ring. The Dykespattern ring's resistance to inertia produced float is provided by its groove, and the clearances there. The lower leg of the ring fits into a deep section of the ring groove, and there is less vertical clearance here than for the upper leg. Therefore, if inertia should lift the ring, it will be stopped by the lower leg while there is still enough clearance to admit gas pressure behind the upper leg.

Generally, the thin, racing version of the conventional piston ring will give perfectly satisfactory results at piston acceleration rates up to 100,000 ft/sec2 or slightly more. Above that, the Dykes-pattern ring is the only one that has consistently been reliable, and only then when made of special materials. Its shape will prevent it from floating, but that does not remove the destructive effects of high acceleration loads. Still, these rings (in alloy steel) have been successful in engines with piston acceleration rates approaching 150,000 ft/sec2. And, of course, they have been a standard fitting in AJS 7-R and Matchless G-50 racing engines. In that application, as in most four-stroke engines, the Dykes ring is used in conjunction with a conventional ring. The Dykes ring is located at the top of the piston, and does the pressure sealing. The second, conventional, ring serves primarily as an oil scraper, for the Dykes ring tends to "relax" during the intake stroke and will give the oil virtually a free passage past the piston. Thus, the necessity for providing a second "compression" ring. Actually, insofar as gas-sealing is concerned, a single Dykes ring will do the job very nicely.

(Continued on page 16)

When used in a two-stroke engine, the Dykes ring has an added advantage: It can be located right up at the piston crown, with the top of the upper leg exposed, and thus located it gives very precise opening and closing points as it zips past the port windows. With any ring positioned down from the crown, there is a brief period of leakage between the time the ring passes the port, and the arrival of the piston's top. However, the Dykes ring does not always seem to work in two-strokes. While it has been extremely serviceable and successful in such engines as the Spanish Bultaco and Montesa, some other engines have shown a tendency toward ring-sticking. Hard-carbon and varnish have frozen the Dykes rings in some test engines in as little as an hour of running. •

View Full Issue

View Full Issue

More From This Issue

-

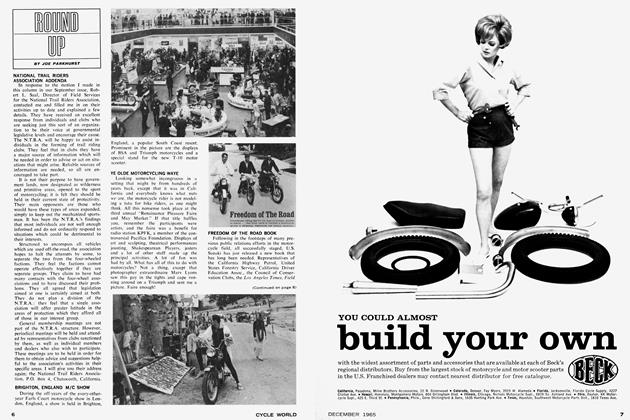

Round Up

December 1965 By Joe Parkhurst -

The Service Department

December 1965 By Gary Bray -

Letter

LetterLetter

December 1965 -

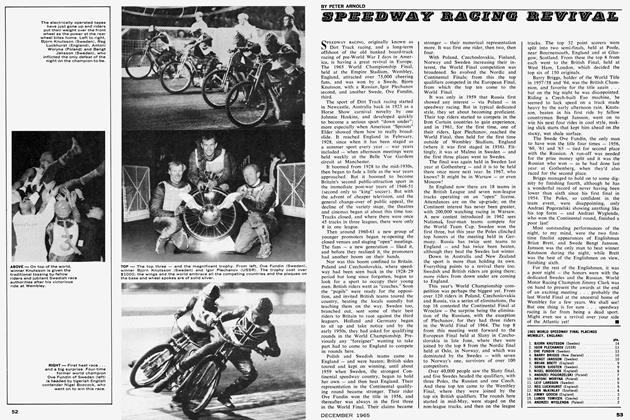

Speed Way Racing Reviyal

December 1965 By Peter Arnold -

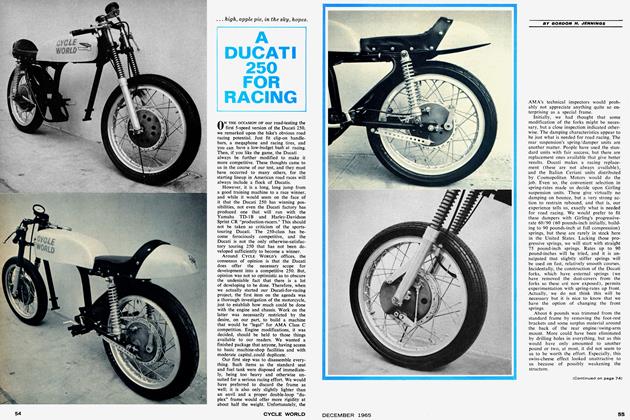

A Ducati 250 For Racing

December 1965 By Gordon H. Jennings -

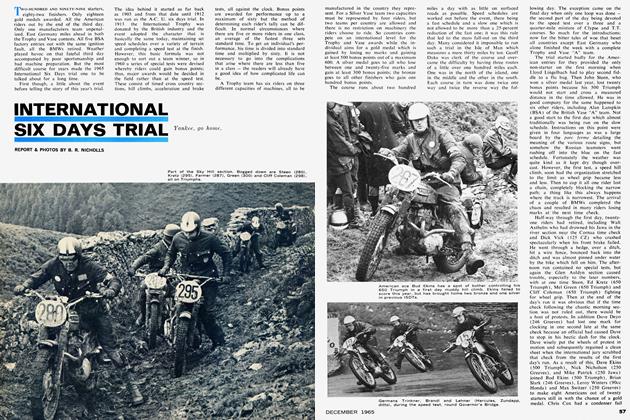

International Six Days Trial Yankee, Go Home.

December 1965 By B. R. Nicholls

![[technicalities]](https://cycleworld.blob.core.windows.net/cycleworld19651201thumbnails/Spreads/0x600/7.jpg)