FROM THE FOUNDRY

ELEMENTS

Motorcycling Started with Cast-Iron

KEVIN CAMERON

Iron is an element, and steel is an alloy of iron with a very small amount of carbon. In practical terms, cast-iron came to mean a combination of iron with so much carbon that most of it is present as inclusions of free, flaky graphite. An early—and enduring—use of cast iron was as the five arching beams with two hinged elements each that support the 100-foot Iron Bridge in England, built in the late 18th century. Each beam was cast in an open sand mold, and there were 368 tons of iron in the bridge.

Yet cast iron had important limits under high stress. Years of study and experiment were needed to make cast iron cannon the equal of brass. The inclusions of graphite in iron weakened it, and certain other impurities—notably phosphorous— had to be carefully excluded.

The Industrial Revolution revealed iron as capable of being cast into complex shapes such as the cylinders and valve bodies of steam engines, or as major frame parts for rolling stock.

Iron was decently machinable— for contrast, try drilling or turning squeaky stainless steel or titanium!—and best of all, it provided a very long-wearing friction surface. The metal is durable and its machined surfaces present myriad oil-retaining cavities that make it eminently “wettable.”

Not at all wettable was one of the first alternatives to iron cylinders—hard chromium plated directly onto the bores of aluminum cylinders—first practiced by Guzzi in the 1950s. Oil refused to wet it, drawing up into droplets that left the surrounding chrome dry as a bone. Only when the plating process was intentionally reversed, etching tiny pits into the surface, could it retain oil.

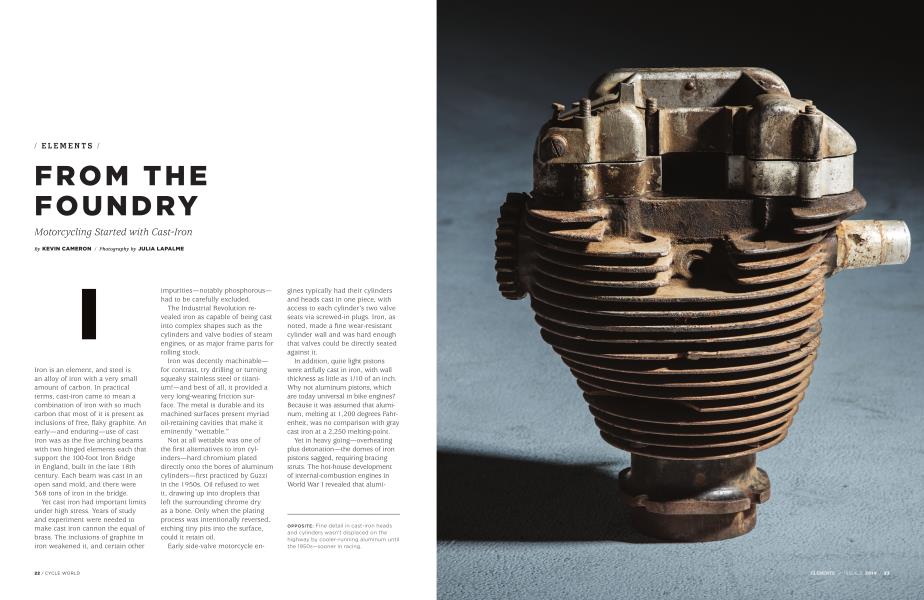

Early side-valve motorcycle engines typically had their cylinders and heads cast in one piece, with access to each cylinder’s two valve seats via screwed-in plugs. Iron, as noted, made a fine wear-resistant cylinder wall and was hard enough that valves could be directly seated against it.

In addition, quite light pistons were artfully cast in iron, with wall thickness as little as 1/10 of an inch. Why not aluminum pistons, which are today universal in bike engines? Because it was assumed that aluminum, melting at 1,200 degrees Fahrenheit, was no comparison with gray cast iron at a 2,250 melting-point.

Yet in heavy going—overheating plus detonation—the domes of iron pistons sagged, requiring bracing struts. The hot-house development of internal-combustion engines in World War I revealed that aluminum’s superior heat conductivity allowed pistons made of it to run much cooler than iron equivalents.

The casting of motorcycle cylinders reached wonderful sophistication during the 1920s, as every increase in power had to be countered by a like increase in total cooling fin area.

One big change was the switch from side-valve to overhead valve in the early to mid-1920s—with detachable cylinder heads.

The low heat conductivity of iron, combined with steadily-rising engine power, brought that era to an end. The first alternative to iron was aluminum-bronze, which was hard enough for valve seating and gave a 60 percent improvement in heat conductivity.

When even higher heat dissipation was required, bimetallic heads were made consisting of a bronze skull in which the combustion chamber, valve openings and spark plug hole were made, with extensive high-conductivity aluminum finning cast over it.

Norton continued to use this skull concept on its Manx racing engines through 1949, and Honda adopted it—albeit with iron rather than bronze skulls—in their classic 1960s GP four-strokes. The final step to an all-aluminum head with shrunk-in hard valve seat rings came in the mid-1930s. Even today, some intake-valve seat rings continue to be made of very hard iron.

Even after World War II, of most production bikes continued to be of cast iron, with aluminum cylinders and iron cylinder liners being adopted as engine cooling needs required. For decades, the process of engine rebuilding would include boring the iron or ironlined cylinder to the next oversize, honing to final dimension, then fitting oversize pistons. Iron has been displaced even from this application by improved forms of hard plating directly upon aluminum cylinders—typically Mahle’s Nikasil. (Mahle is a respected German piston manufacturer.)

In a typical four-cylinder motorcycle engine, switching from iron liners to hard plating on aluminum saves 6 pounds of weight. Modern lubricant additives, liquid cooling, and digital fuel and ignition controls have made the old 25,000mile rebore unnecessary.

The crankshafts of the earliest motorcycle engines were made from five pieces—two mainshafts and a crankpin, made of steel, and two cast-iron flywheels, assembled by tapers, keys, and thin nuts. As the rpm of peak power rose, inertia loads increased, sometimes allowing the steel parts to work loose in the weaker iron.

At first, flywheels for racing were switched to steel, but soon iron wheels had to be given up even in production engines. Today’s cranks are forged in a single piece of steel, carrying split-and-bolted plain-bearing connecting rods.

Through about 1970, piston rings were also of cast iron, which during break-in was easily “filed” into a good fit by a prominent crosshatch hone pattern on iron cylinder walls. Really high power and temperature arrived first in aircraft piston engines, for which the top rings were hard-chrome plated from 1941 onward to extend their wear life. First ductile iron, then steel replaced basic cast iron as a piston-ring material.

Because of the good friction properties of iron, aluminum drum brakes were given iron liners against which the brake shoes pressed the friction material. Iron for a time found use in brake discs as well, but the “scratchy” nature of recent metal-ceramic friction pad material has required use of much harder stainless discs.

Iron, once widely used in motorcycles because of its low cost, durability, and versatility, has been driven out of one application after another by the need to reduce weight or to increase strength.

View Full Issue

View Full Issue

More From This Issue

-

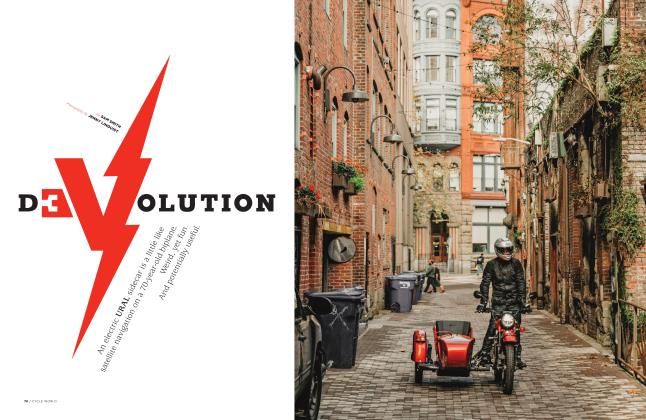

Devolution

Issue 2 2019 By Sam Smith -

Feature

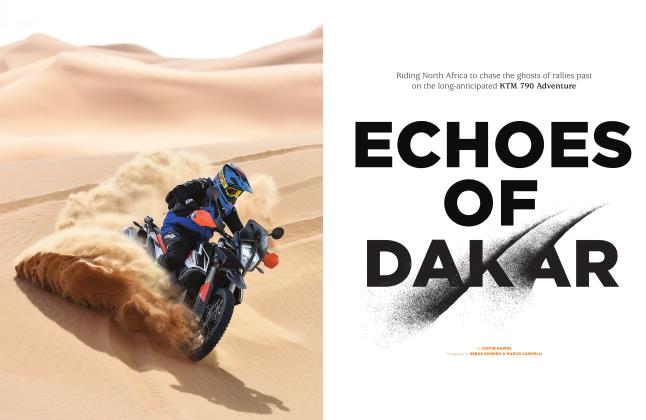

FeatureEchoes of Dakar

Issue 2 2019 By Justin Dawes -

TDC

TDCWhen the Engine Starts

Issue 2 2019 By Kevin Cameron -

Reviews

ReviewsBalance of Power

Issue 2 2019 By Michael Gilbert -

Reviews

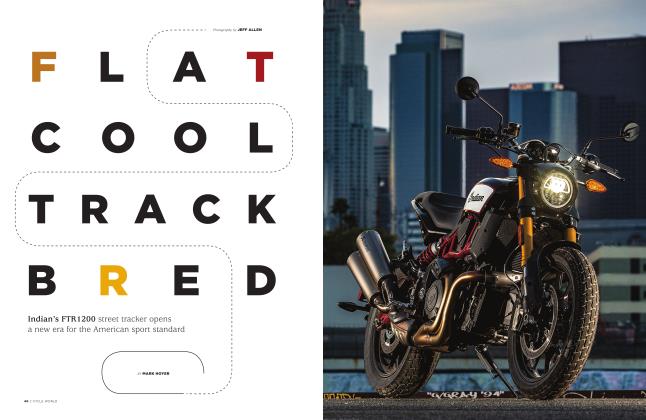

ReviewsFlat Cool Track Bred

Issue 2 2019 By Mark Hoyer -

Origins

OriginsThe First Superbike

Issue 2 2019 By Kevin Cameron