Imminent Specific Progress

Why did electric automaker Tesla buy Maxwell Technologies?

September 1 2019 Kevin CameronWhy did electric automaker Tesla buy Maxwell Technologies?

September 1 2019 Kevin CameronIMMINENT SPECIFIC PROGRESS

TDC

Why did electric automaker Tesla buy Maxwell Technologies?

KEVIN CAMERON

It is with trepidation that I write even one word about this. A few years ago, seeing the interest in electric vehicles, I wrote a five-part descriptive article for cycleworld.com on electric motors, their power supplies, lithium-ion batteries themselves, battery charging, and so on. I might as well have written about deflagration of monodisperse sprays for all the interest those stories generated. I concluded that our readers, while possibly wowed by the novelty of electric motorcycles, did not want to know anything about how they work.

Electric motors and their power supplies are already sophisticated and affordable; the barrier to wide use of electric vehicles is their batteries, which remain expensive, heavy, and limited in driving range.

Lithium-ion batteries were conceived in 1975, commercialized by Sony in 1992, and have improved by a few percent a year since then as a result of a great many labs constantly at work on their problems worldwide. Hardly a day goes by without one of the gee-whiz technology sites reporting a “breakthrough that could revolutionize transportation.” Because life goes on as before, the dull roar of such announcements lulls us to sleep.

But when engineer and Cycle World contributor Steve Anderson told me about electric automaker Tesla buying Maxwell Technologies in May, the emerging story predicted a near-term 50 percent improvement in li-ion specific energy, and a 10 to 20 percent cost reduction with a longer-term potential for a 2.5 times specific energy gain.

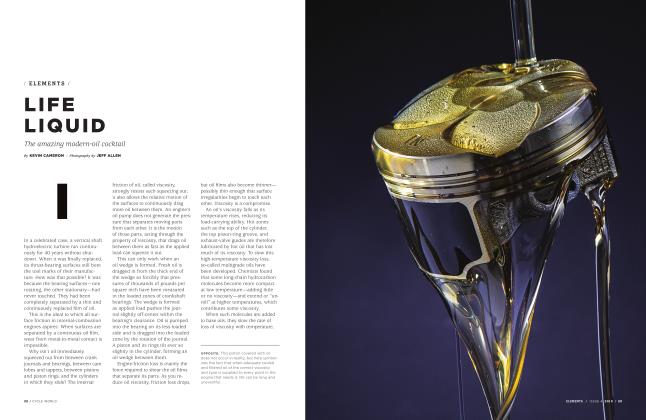

The electrodes of li-ion batteries usually take the form of thin metal foils coated with “active materials.” These are the familiar electrode chemistries—LTO, NMC, LMO, LCO, and so on. (I keep a magic decoder ring for this in a filing cabinet.)

To conduct electricity from active material to metal foil, a percentage of finely divided carbon is also required, and to hold all this together, there must be a binder. The usual method makes a paste or liquid of these three by use of a solvent that dissolves the binder. This paste is then applied to a continuous strip of metal foil (called a current collector) by some form of roll processing. It is later cut into suitable sizes to be rolled up into cylindrical cells, or used in flat form in “pouch” cells.

Trouble is, binders durable enough to survive long-term exposure to battery electrolyte require some pretty stout solvents. Descriptives applied to such solvents include “potent liver toxin,” “reproductive toxicant,” and “damage to liver, kidneys, and lungs.”

To evaporate the solvent, leaving the finished electrode in coated sheet form (sometimes on both sides), the material passes through a drying oven. The thicker the coating, the more hours it takes to evaporate the solvent, but the thinner the coating, the lower the specific energy of the battery. And the EPA is there making sure you capture and recycle every molecule of “potent liver toxin.” All this increases costs, driving a desperate search for a “dry” (that is, solvent-free) electrode coating process. Please save us from acres of electrically heated drying ovens.

The number of patents in this and related areas is stupefying. And they are repetitious, paragraph after paragraph that differ in only a single word. (Gotta cover the waterfront 100 percent, or some clever bunch of attorneys in green eyeshades will break your patent!) But the people at Tesla must have plowed through it because they learned that Maxwell Technologies in San Diego has just such a dry coating process. Maxwell’s business is the production of ultracapacitors, which also require coatings applied to metal foils.

It turns out that Teflon, that wonderfully slippery and chemically unreactive white plastic, can be “unwound.” Its long chains of bonded carbon and fluorine, normally packed together, can be “fibrillated” by subjecting it to intense shear stress. When mixed with the active material of a li-ion battery electrode plus a measure of conductive carbon, then passed through a screw extruder with a suitable reduction ratio, what comes out is a stringy mass of sub-10-micron Teflon fibrils immobilizing and containing the other solid ingredients. No poisonous solvents. It can then form a self-supporting continuous sheet.

Maxwell didn’t invent this; read Olle Nilsson’s 1978 US Patent 4110519, which describes—41 years ago—fibrillizing Teflon to immobilize lead oxide in ordinary lead-acid batteries. So, what does Maxwell have for which Tesla would trade $288 million worth of its shares? Maybe a sure method of bonding nothingsticks-to-it Teflon onto metal foils?

“The barrier to wide use of electric vehicles is their batteries.”

Or is it a particular kind of fibrillization that holds the dry ingredients tightly together, ensuring long-term conductivity? Or could it be the prolific mind of Linda Zhong, senior director of research and development at Maxwell, whose name is on so very many patents?

Aside from the process being dry, the use of Teflon as a binder has other important advantages. It covers the very minimum surface of the active material, thereby exposing more of it to battery electrolyte. Wet process binders such as PVDF (OK, you asked for it: polyvinylidene fluoride) tend to inactivate a lot of surface. There is also no evident impediment to depositing thicker coatings of up to 2 mm (0.08 inch). As noted above, thicker coatings store more energy. The limit to this is the conductivity of the coating. As movement of li-ions produces electrical current, it must trickle through a great many points of contact between particles of active material and conductive carbon. Electricity flowing through resistance generates heat (laptops could just as well be called lap warmers because of this very effect).

And there’s another point: In general, when you increase the specific energy of a li-ion battery, you also slow down its rates of charge and discharge. That means you might very well increase the specific energy of your electric car’s battery by 50 percent with the above dry coating process, but that might not translate to zippy performance up the freeway on-ramp. That’s why, in some applications, ultracapacitors are used together with li-ion batteries. Capacitors charge and discharge right now, so as we “hit the gas” to accelerate, the prompt electricity will come from the ultracapacitors. Long-term cruise will be supplied from the battery, which will also recharge the capacitors. Capacitors also work well with regenerative braking—they can accept such power a lot faster than a li-ion battery—and with less resistance loss. Maxwell manufactures such capacitors.

Present estimates for when such dry-process batteries might enter Tesla production speak of 2022 or later. But who, outside of corporate boardrooms littered with doughnut boxes and coffee cups, really knows?

BY THE NUMBERS

1975

Year lithium-ion batteries were conceived

$288M

Value of shares Tesla traded for Maxwell Technologies

1992

Year lithium-ion batteries were commercialized by Sony

View Full Issue

View Full Issue