The Opposite of Engines

TDC

KEVIN CAMERON

FOR ME, THE GREATEST THING ABOUT being at the races is that the highest technologies are on show there, often attended by the very engineers who created them. This past summer at the Indianapolis Grand Prix, I had the extraordinary privilege of a private tutorial on GP motorcycle brakes, given by veteran Brembo engineer Eugenio Gandolfi.

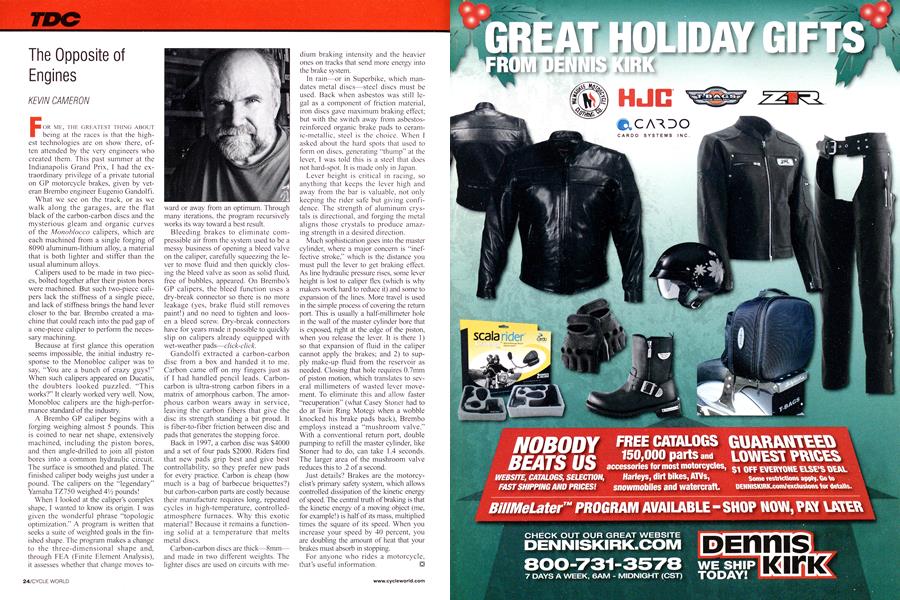

What we see on the track, or as we walk along the garages, are the flat black of the carbon-carbon discs and the mysterious gleam and organic curves of the Monoblocco calipers, which are each machined from a single forging of 8090 aluminum-lithium alloy, a material that is both lighter and stiffer than the usual aluminum alloys.

Calipers used to be made in two pieces, bolted together after their piston bores were machined. But such two-piece calipers lack the stiffness of a single piece, and lack of stiffness brings the hand lever closer to the bar. Brembo created a machine that could reach into the pad gap of a one-piece caliper to perform the necessary machining.

Because at first glance this operation seems impossible, the initial industry response to the Monobloc caliper was to say, “You are a bunch of crazy guys!” When such calipers appeared on Ducatis, the doubters looked puzzled. “This works?” It clearly worked very well. Now, Monobloc calipers are the high-performance standard of the industry.

A Brembo GP caliper begins with a forging weighing almost 5 pounds. This is coined to near net shape, extensively machined, including the piston bores, and then angle-drilled to join all piston bores into a common hydraulic circuit. The surface is smoothed and plated. The finished caliper body weighs just under a pound. The calipers on the “legendary” Yamaha TZ750 weighed 414 pounds!

When I looked at the caliper’s complex shape, I wanted to know its origin. I was given the wonderful phrase “topologie optimization.” A program is written that seeks a suite of weighted goals in the finished shape. The program makes a change to the three-dimensional shape and, through FEA (Finite Element Analysis), it assesses whether that change moves to-

ward or away from an optimum. Through many iterations, the program recursively works its way toward a best result.

Bleeding brakes to eliminate compressible air from the system used to be a messy business of opening a bleed valve on the caliper, carefully squeezing the lever to move fluid and then quickly closing the bleed valve as soon as solid fluid, free of bubbles, appeared. On Brembo’s GP calipers, the bleed function uses a dry-break connector so there is no more leakage (yes, brake fluid still removes paint!) and no need to tighten and loosen a bleed screw. Dry-break connectors have for years made it possible to quickly slip on calipers already equipped with wet-weather pads—click-click.

Gandolfi extracted a carbon-carbon disc from a box and handed it to me. Carbon came off on my fingers just as if I had handled pencil leads. Carboncarbon is ultra-strong carbon fibers in a matrix of amorphous carbon. The amorphous carbon wears away in service, leaving the carbon fibers that give the disc its strength standing a bit proud. It is fiber-to-fiber friction between disc and pads that generates the stopping force.

Back in 1997, a carbon disc was $4000 and a set of four pads $2000. Riders find that new pads grip best and give best controllability, so they prefer new pads for every practice. Carbon is cheap (how much is a bag of barbecue briquettes?) but carbon-carbon parts are costly because their manufacture requires long, repeated cycles in high-temperature, controlledatmosphere furnaces. Why this exotic material? Because it remains a functioning solid at a temperature that melts metal discs.

Carbon-carbon discs are thick—8mm— and made in two different weights. The lighter discs are used on circuits with me-

dium braking intensity and the heavier ones on tracks that send more energy into the brake system.

In rain—or in Superbike, which mandates metal discs—steel discs must be used. Back when asbestos was still legal as a component of friction material, iron discs gave maximum braking effect; but with the switch away from asbestosreinforced organic brake pads to ceramic-metallic, steel is the choice. When 1 asked about the hard spots that used to form on discs, generating “thump” at the lever, I was told this is a steel that does not hard-spot. It is made only in Japan.

Lever height is critical in racing, so anything that keeps the lever high and away from the bar is valuable, not only keeping the rider safe but giving confidence. The strength of aluminum crystals is directional, and forging the metal aligns those crystals to produce amazing strength in a desired direction.

Much sophistication goes into the master cylinder, where a major concern is “ineffective stroke,” which is the distance you must pull the lever to get braking effect. As line hydraulic pressure rises, some lever height is lost to caliper flex (which is why makers work hard to reduce it) and some to expansion of the lines. More travel is used in the simple process of covering the return port. This is usually a half-millimeter hole in the wall of the master cylinder bore that is exposed, right at the edge of the piston, when you release the lever. It is there 1 ) so that expansion of fluid in the caliper cannot apply the brakes; and 2) to supply make-up fluid from the reservoir as needed. Closing that hole requires 0.7mm of piston motion, which translates to several millimeters of wasted lever movement. To eliminate this and allow faster “recuperation” (what Casey Stoner had to do at Twin Ring Motegi when a wobble knocked his brake pads back), Brembo employs instead a “mushroom valve.” With a conventional return port, double pumping to refill the master cylinder, like Stoner had to do, can take 1.4 seconds. The larger area of the mushroom valve reduces this to .2 of a second.

Just details? Brakes are the motorcyclist’s primary safety system, which allows controlled dissipation of the kinetic energy of speed. The central truth of braking is that the kinetic energy of a moving object (me, for example!) is half of its mass, multiplied times the square of its speed. When you increase your speed by 40 percent, you are doubling the amount of heat that your brakes must absorb in stopping.

For anyone who rides a motorcycle, that's useful information.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Impressionable Mind

JANUARY 2012 By Mark Hoyer -

Roundup

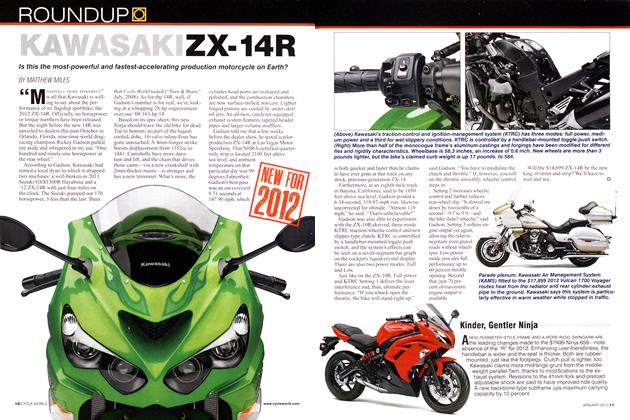

RoundupKawasakizx-14r

JANUARY 2012 By Matthew Miles -

Roundup

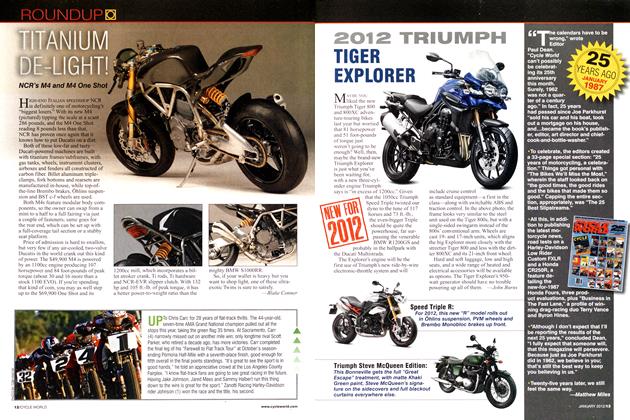

RoundupTitanium De-Light!

JANUARY 2012 By Blake Conner -

Roundup

Roundup2012 Triumph Tiger Explorer

JANUARY 2012 By John Burns -

Roundup

Roundup25 Years Ago January 1987

JANUARY 2012 By John Burns -

Roundup

RoundupMarco Simoncelli, 1987-2011

JANUARY 2012 By Kevin Cameron