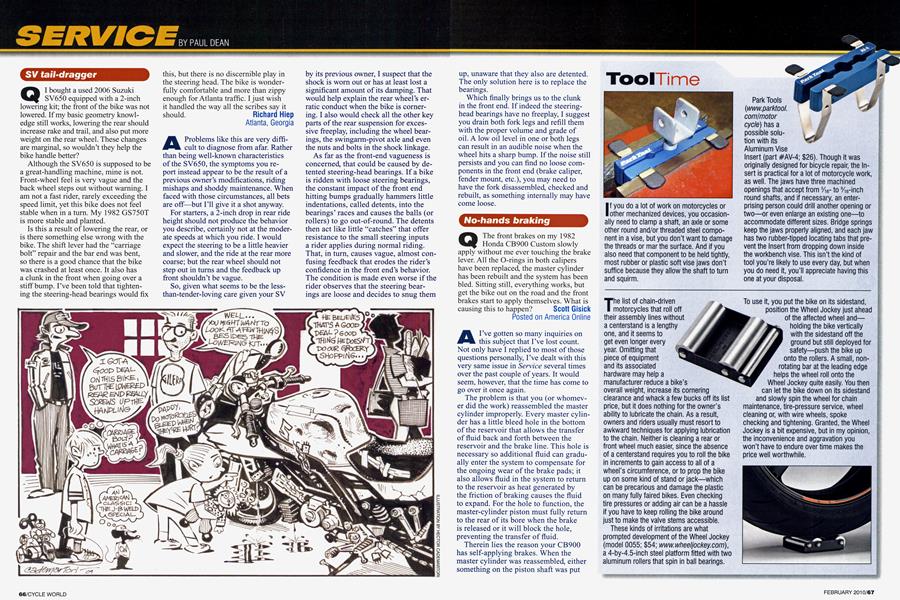

ToolTime

If you do a lot of work on motorcycles or other mechanized devices, you occasionally need to clamp a shaft, an axle or some other round and/or threaded steel component in a vise, but you don’t want to damage the threads or mar the surface. And if you also need that component to be held tightly, most rubber or plastic soft vise jaws don’t suffice because they allow the shaft to turn and squirm.

Park Tools {www.parktool. com/motor cycle) has a possible solution with its Aluminum Vise Insert (part #AV-4; $26). Though it was originally designed for bicycle repair, the Insert is practical for a lot of motorcycle work, as well. The jaws have three machined openings that accept from 5/16to 9/i6-inch round shafts, and if necessary, an enterprising person could drill another opening or two—or even enlarge an existing one—to accommodate different sizes. Bridge springs keep the jaws properly aligned, and each jaw has two rubber-tipped locating tabs that prevent the Insert from dropping down inside the workbench vise. This isn’t the kind of tool you’re likely to use every day, but when you do need it, you’ll appreciate having this one at your disposal.

The list of chain-driven motorcycles that roll off their assembly lines without a centerstand is a lengthy one, and it seems to get even longer every year. Omitting that piece of equipment and its associated hardware may help a

manufacturer reduce a bike’s overall weight, increase its cornering clearance and whack a few bucks off its list price, but it does nothing for the owner’s ability to lubricate the chain. As a result, owners and riders usually must resort to awkward techniques for applying lubrication to the chain. Neither is cleaning a rear or front wheel much easier, since the absence of a centerstand requires you to roll the bike in increments to gain access to all of a wheel’s circumference, orto prop the bike up on some kind of stand or jack—which can be precarious and damage the plastic on many fully faired bikes. Even checking tire pressures or adding air can be a hassle if you have to keep rolling the bike around just to make the valve stems accessible.

These kinds of irritations are what prompted development of the Wheel Jockey (model 0055; $54; www.wheeljockey.com), a 4-by-4.5-inch steel platform fitted with two aluminum rollers that spin in ball bearings.

To use it, you put the bike on its sidestand, position the Wheel Jockey just ahead of the affected wheel and— holding the bike vertically with the sidestand off the ground but still deployed for safety—push the bike up onto the rollers. A small, nonrotating bar at the leading edge helps the wheel roll onto the Wheel Jockey quite easily. You then can let the bike down on its sidestand and slowly spin the wheel for chain maintenance, tire-pressure service, wheel cleaning or, with wire wheels, spoke checking and tightening. Granted, the Wheel Jockey is a bit expensive, but in my opinion, the inconvenience and aggravation you won’t have to endure over time makes the price well worthwhile.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSeizing the Means of Production

FEBRUARY 2010 By Mark Hoyer -

Roundup

RoundupSexysix

FEBRUARY 2010 By Bruno Deprato -

Roundup

RoundupKiller Concepts

FEBRUARY 2010 By Bruno Deprato -

Roundup

Roundup2010 Mv Agusta F4

FEBRUARY 2010 By Bruno Deprato -

Roundup

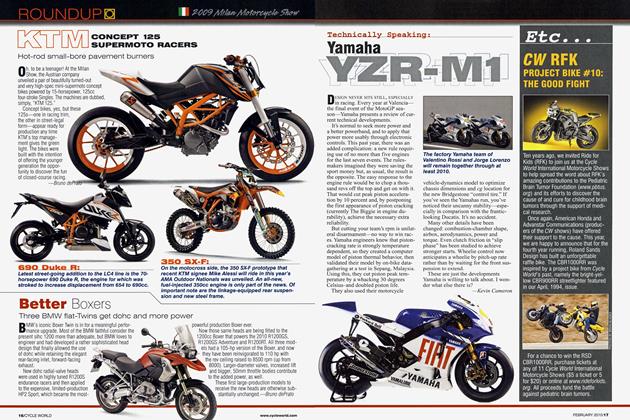

RoundupKtm Concept 125 Supermoto Racers

FEBRUARY 2010 By Bruno Deprato -

Roundup

RoundupBetter Boxers

FEBRUARY 2010 By Bruno Deprato