UP FRONT

ON DYNO TESTING SUSPENSION: HOW TO READ THE CHARTS AND WHAT CAN BE LEARNED

SEAT-OF-THE-PANTS evaluation is necessary today and it will be necessary in the future, because whether or not a motorcycle works well in practice is the final truth. But, explaining exactly what is happening to component parts (like suspension) and then determining whether problems can be cured easily, is well beyond the realm of conventional testing.

So, in order to present a clearer picture, we contacted Number One Products in Whittier, Calif. Our aim was to develop a dyno test for suspension that would be informative to the general public and that could be carried out on every machine we evaluate. We are now about halfway there, and, beginning with this issue, we are presenting suspension dyno tests as part of our dirt bike evaluations.

The dyno charts and basic format will not change with future issues, but more comparative data will be included.

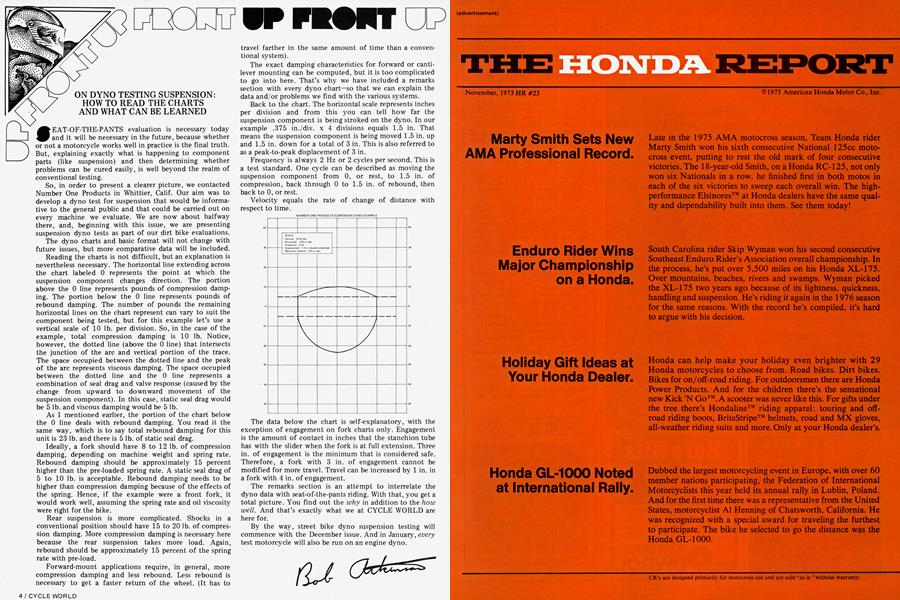

Reading the charts is not difficult, but an explanation is nevertheless necessary. The horizontal line extending across the chart labeled 0 represents the point at which the suspension component changes direction. The portion above the 0 line represents pounds of compression damping. The portion below the 0 line represents pounds of rebound damping. The number of pounds the remaining horizontal lines on the chart represent can vary to suit the component being tested, but for this example let’s use a vertical scale of 10 lb. per division. So, in the case of the example, total compression damping is 10 lb. Notice, however, the dotted line (above the 0 line) that intersects the junction of the arc and vertical portion of the trace. The space occupied between the dotted line and the peak of the arc represents viscous damping. The space occupied between the dotted line and the 0 line represents a combination of seal drag and valve response (caused by the change from upward to downward movement of the suspension component). In this case, static seal drag would be 5 lb. and viscous damping would be 5 lb.

As I mentioned earlier, the portion of the chart below the 0 line deals with rebound damping. You read it the same way, which is to say total rebound damping for this unit is 23 lb. and there is 5 lb. of static seal drag.

Ideally, a fork should have 8 to 12 lb. of compression damping, depending on machine weight and spring rate. Rebound damping should be approximately 15 percent higher than the pre-loaded spring rate. A static seal drag of 5 to 10 lb. is acceptable. Rebound damping needs to be higher than compression damping because of the effects of the spring. Hence, if the example were a front fork, it would work well, assuming the spring rate and oil viscosity were right for the bike.

Rear suspension is more complicated. Shocks in a conventional position should have 15 to 20 lb. of compression damping. More compression damping is necessary here because the rear suspension takes more load. Again, rebound should be approximately 15 percent of the spring rate with pre-load.

Forward-mount applications require, in general, more compression damping and less rebound. Less rebound is necessary to get a faster return of the wheel. (It has to travel farther in the same amount of time than a conventional system).

The exact damping characteristics for forward or cantilever mounting can be computed, but it is too complicated to go into here. That’s why we have included a remarks section with every dyno chart—so that we can explain the data and/or problems we find with the various systems.

Back to the chart. The horizontal scale represents inches per division and from this you can tell how far the suspension component is being stroked on the dyno. In our example .375 in./div. x 4 divisions equals 1.5 in. That means the suspension component is being moved 1.5 in. up and 1.5 in. down for a total of 3 in. This is also referred to as a peak-to-peak displacement of 3 in.

Frequency is always 2 Hz or 2 cycles per second. This is a test standard. One cycle can be described as moving the suspension component from 0, or rest, to 1.5 in. of compression, back through 0 to 1.5 in. of rebound, then back to 0, or rest.

Velocity equals the rate of change of distance with respect to time.

The data below the chart is self-explanatory, with the exception of engagement on fork charts only. Engagement is the amount of contact in inches that the stanchion tube has with the slider when the fork is at full extension. Three in. of engagement is the minimum that is considered safe. Therefore, a fork with 3 in. of engagement cannot be modified for more travel. Travel can be increased by 1 in. in a fork with 4 in. of engagement.

The remarks section is an attempt to interrelate the dyno data with seat-of-the-pants riding. With that, you get a total picture. You find out the why in addition to the how well. And that’s exactly what we at CYCLE WORLD are here for.

By the way, street bike dyno suspension testing will commence with the December issue. And in January, every test motorcycle will also be run on an engine dyno.

View Full Issue

View Full Issue