THROTTLE BY WIRE

ROUNDUP

A closer look at motorcycling's next technological trend

KEVIN CAMERON

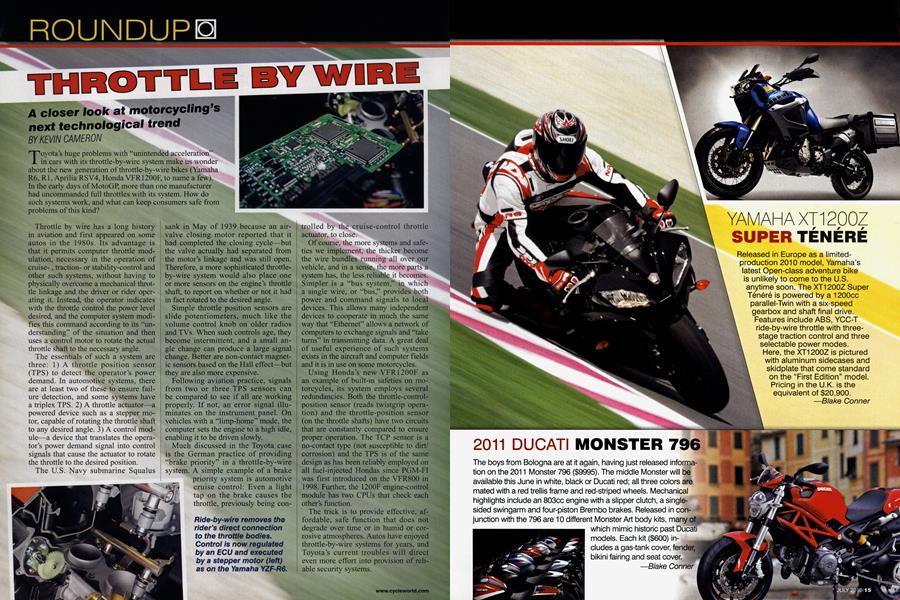

Toyota's huge problems with "unintended acceleration" in cars with its throttle-by-wire system make us wonder about the new generation of throttle-by-wire bikes (Yamaha R6, R1, Aprilia RSV4, Honda VFR 1200F, to name a few). In the early days of MotoGP, more than one manufacturer had uncommanded full throttles with its system. How do such systems work, and what can keep consumers safe from problems of this kind?

Throttle by wire has a long history in aviation and first appeared on some autos in the 1980s. Its advantage is that it permits computer throttle modulation, necessary in the operation of cruise-, tractionor stability-control and other such systems, without having to physically overcome a mechanical throttle linkage and the driver or rider operating it. Instead, the operator indicates with the throttle control the power level desired, and the computer system modifies this command according to its “understanding” of the situation and then uses a control motor to rotate the actual throttle shaft to the necessary angle.

The essentials of such a system are three: 1) A throttle position sensor (TPS) to detect the operator’s power demand. In automotive systems, there are at least two of these to ensure failure detection, and some systems have a triplex TPS. 2) A throttle actuator—a powered device such as a stepper motor, capable of rotating the throttle shaft to any desired angle. 3) A control module—a device that translates the operator’s power demand signal into control signals that cause the actuator to rotate the throttle to the desired position.

The U.S. Navy submarine Squalus sank in May of 1939 because an airvalve closing motor reported that it had completed the closing cycle—but the valve actually had separated from the motor’s linkage and was still open. Therefore, a more sophisticated throttleby-wire system would also place one or more sensors on the engine’s throttle shaft, to report on whether or not it had in fact rotated to the desired angle.

Simple throttle position sensors are slide potentiometers, much like the volume control knob on older radios and TVs. When such controls age, they become intermittent, and a small angle change can produce a large signal change. Better are non-contact magnetic sensors based on the Hall effect—but they are also more expensive.

Following aviation practice, signals from two or three TPS sensors can be compared to see if all are working properly. If not, an error signal illuminates on the instrument panel. On vehicles with a “limp-home” mode, the computer sets the engine to a high idle, enabling it to be driven slowly.

Much discussed in the Toyota case is the German practice of providing “brake priority” in a throttle-by-wire system. A simple example of a brake priority system is automotive cruise control: Even a light tap on the brake causes the throttle, previously being controlled by the cruise-control throttle actuator, to close.

Of course, the more systems and safeties we implement, the thicker become the wire bundles running all over our vehicle, and in a sense, the more parts a system has, the less reliable it becomes. Simpler is a “bus system,” in which a single wire, or “bus,” provides both power and command signals to local devices. This allows many independent devices to cooperate in much the same way that “Ethernet” allows a network of computers to exchange signals and “take turns” in transmitting data. A great deal of useful experience of such systems exists in the aircraft and computer fields and it is in use on some motorcycles.

Using Honda’s new VFR1200F as an example of built-in safeties on motorcycles, its system employs several redundancies. Both the throttle-controlposition sensor (reads twistgrip operation) and the throttle-position sensor (on the throttle shafts) have two circuits that are constantly compared to ensure proper operation. The TCP sensor is a no-contact type (not susceptible to dirt/ corrosion) and the TPS is of the same design as has been reliably employed on all fuel-injected Hondas since PGM-FI was first introduced on the VFR800 in 1998. Further, the 1200F engine-control module has two CPUs that check each other’s function.

The trick is to provide effective, affordable, safe function that does not degrade over time or in humid or corrosive atmospheres. Autos have enjoyed throttle-by-wire systems for years, and Toyota’s current troubles will direct even more effort into provision of reliable security systems.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontRisk Management

JULY 2010 By Mark Hoyer -

Roundup

RoundupTeam Cycle World

JULY 2010 By Kevin Cameron -

Roundup

RoundupWill the Real F4 Please Stand Up?

JULY 2010 By Blake Conner -

Roundup

RoundupMiddleweight Eight!

JULY 2010 By Blake Conner -

Roundup

Roundup25 Years Ago July 1985

JULY 2010 By Blake Conner -

Roundup

RoundupUps & Downs

JULY 2010