STARS & STRIPES FOREVER

An XR-750 street-tracker returns to the road

ALLAN GIRDLER

THERE'S NOTHING QUITE LIKE THE motivation provided by being shamed and disgraced in front of one's peers.

As in?

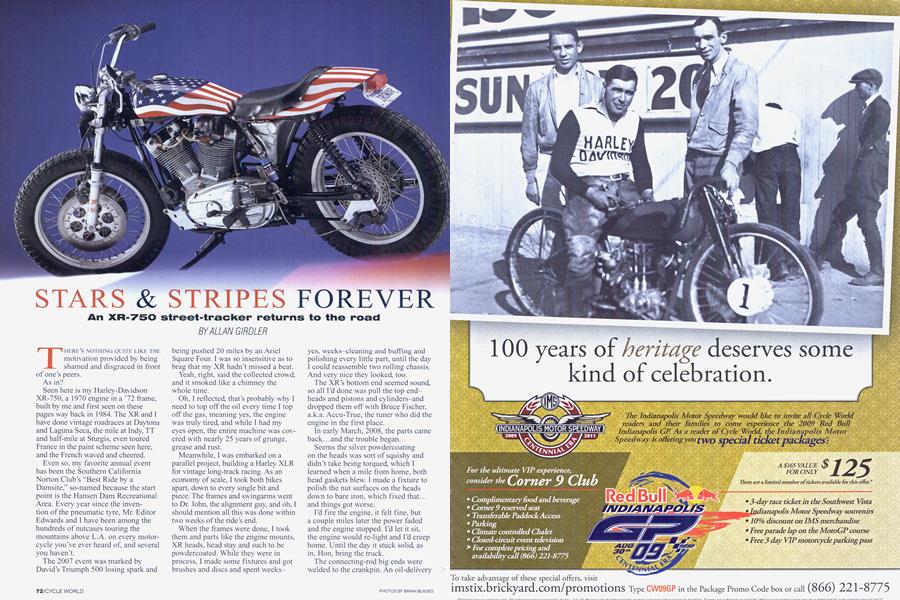

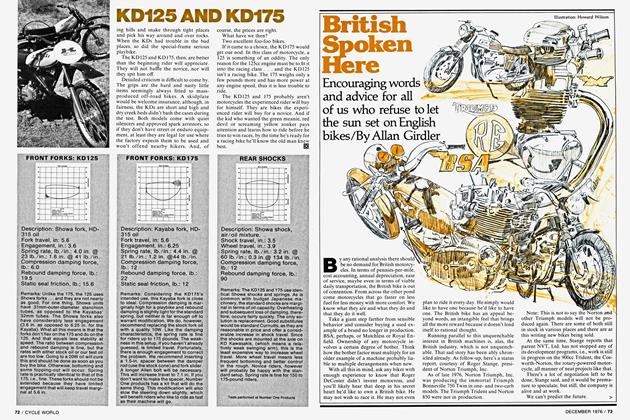

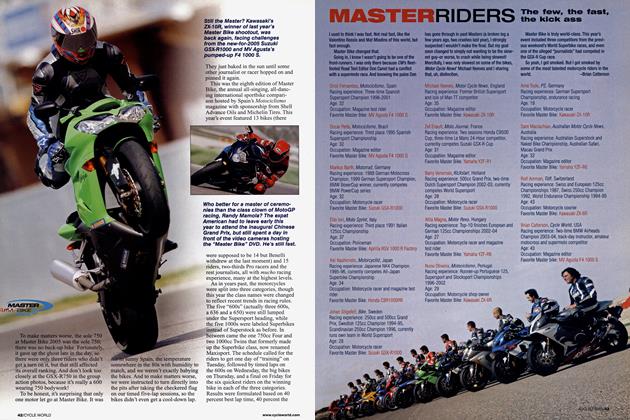

Seen here is my Harley-Davidson XR-750, a 1970 engine in a ’72 frame, built by me and first seen on these pages way back in 1984. The XR and I have done vintage roadraces at Daytona and Laguna Seca, the mile at Indy, TT and half-mile at Sturgis, even toured France in the paint scheme seen here, and the French waved and cheered.

Even so, my favorite annual event has been the Southern California Norton Club’s “Best Ride by a Damsite,” so-named because the start point is the Hansen Dam Recreational Area. Every year since the invention of the pneumatic tyre, Mr. Editor Edwards and I have been among the hundreds of nutcases touring the mountains above L.A. on every motorcycle you’ve ever heard of, and several you haven’t.

The 2007 event was marked by David’s Triumph 500 losing spark and being pushed 20 miles by an Ariel Square Four. I was so insensitive as to brag that my XR hadn’t missed a beat.

Yeah, right, said the collected crowd, and it smoked like a chimney the whole time.

Oh, I reflected, that’s probably why I need to top off the oil every time I top off the gas, meaning yes, the engine was truly tired, and while I had my eyes open, the entire machine was covered with nearly 25 years of grunge, grease and rust.

Meanwhile, I was embarked on a parallel project, building a Harley XLR for vintage long-track racing. As an economy of scale, I took both bikes apart, down to every single bit and piece. The frames and swingarms went to Dr. John, the alignment guy, and oh, I should mention all this was done within two weeks of the ride’s end.

When the frames were done, I took them and parts like the engine mounts, XR heads, head stay and such to be powdercoated. While they were in process, I made some fixtures and got brushes and discs and spent weeksyes, weeks—cleaning and buffing and polishing every little part, until the day I could reassemble two rolling chassis.

And very nice they looked, too.

The XR’s bottom end seemed sound, so all I’d done was pull the top endheads and pistons and cylinders-and dropped them off with Bruce Fischer, a.k.a. Accu-True, the tuner who did the engine in the first place.

In early March, 2008, the parts came back.. .and the trouble began.

Seems the silver powdercoating on the heads was sort of squishy and didn’t take being torqued, which I learned when a mile from home, both head gaskets blew. I made a fixture to polish the nut surfaces on the heads down to bare iron, which fixed that... and things got worse.

I’d fire the engine, it felt fine, but a couple miles later the power faded and the engine stopped. I’d let it sit, the engine would re-light and I’d creep home. Until the day it stuck solid, as in, Hon, bring the truck.

The connecting-rod big ends were welded to the crankpin. An oil-delivery failure of some sort, but how it happened I still don’t know.

Not that it makes much difference. An XR race engine is a lot less like an XL street engine on the inside than it looks on the outside. But by happy circumstance, for the XLR project mentioned earlier I’d been collecting connecting rods, crankpins, camshafts and the like, so Bruce agreed on a complete overhaul.

Meanwhile, I’d been washing and polishing and cleaning all the cycle parts. The fiberglass gas tank looked finewell, if you don’t look closely-but the seat/fender was cracked and chipped.

I wanted to keep the flag motif, which was done originally by a gal in Arizona. Too far and too costly, so I kept the tank and bought a new bare seat from First Klass Glass, a flat-track source. New and old pieces went to Uptown Design, the painters who did my dirt-track 450. They painted the new to match the old; nice work, too. By June, 2008, the rolling chassis was back in my work space, clean and shiny as new.

Pause here for a tip of the red-whiteand-blue helmet to Harley-Davidson and the company’s lack of change. Harley racing engines used the same connecting rods from 1952 through 1971, with the crankpins and bearings and cages unchanged for 15 years after that. Thanks to eBay, I got new rods easily, and although the 89R crankpin was too new, the rollers were a match.

And we found a used XL gearcase cover to use with the XR cases modified to run a generator, a perfect fit once the cheap chrome was blasted off. There is so much swapping possible, and the parts were in production for so long, there are even books about what fits what.

Try that on yer Big Four machine.

The star of this project, though, is the exhaust. From the 1984 build until the blow-up, I’d used megaphones with mufflers, coated in what’s sold as indestructible coating.

It’s not. Oil, tar, grease, even a touch of a grimy work glove, marks and stains the coating forever.

As a happy coincidence, I rode David’s BSA 650 in the inaugural Motogiro America rally (see “Viva Motogiro!” CW, December, 2008) and noted the use of VW Bug exhaust tips to knock the edge off its otherwise unbaffled scrambler-style pipes. Nice sound. Cheap. And the guy who owns our local muffler shop is the guy who adapted Mustang stainless-steel tips to my old Ferrari’s mufflers-no, I didn’t make that up, ask me another time.

J&P Cycles provided a set of XLR pipes in chrome; sure, it’s against street-tracker style but chrome shrugs off oil and tar and greasy fingers and I want this restoration to last, eh?

Of course, the pipes didn’t fit, but Eric the muffler guy did a neat job squeezing here, expanding there, fabbing brackets, adapting the VW tips. The engine sounds terrific; I can ride without earplugs for the first time on this bike.

But that’s getting ahead of the rebuild.

On October 6,1 asked Bruce when the engine would be done. Couple weeks, he said. Oh, geez, I said, the Best Dam Ride is November 1, not that I want to push you.

He finished the engine on October 28, I had it in the frame and hooked up on October 31, bumped it with one oil line disconnected to be sure I had pressure... Oh, wow, did I! Oil everywhere. Closed the line, degreased everything, started it again and let it idle...wuff. Stopped. Boy, I thought, that’s the sign of a tight engine.

Next morning, David and I unloaded our bikes. I went to kick, nothing. Would. Not. Turn. Over. I backed it up against compression, tried a bumpstart, again, no turn. I guessed-make that hoped-that the oil had seeped into the crankcase, a malady to which Xseries engines are liable, and did the ride sitting in the sweep truck.

Back home, there wasn’t that much oil in the sump. I took everything apart, working back to front and nothing was wrong in the gearbox, clutch, starter, primary, valvetrain, until I removed the gearcase cover, and when I eased down the kick lever, the engine turned over... and the oil pump drive gear walked out of place.

The pump was stuck solid.

Another odd fact about XR engines is that you can’t remove the oil pump with the engine in the frame. Out came the engine, ditto the pump.

Lodged in one of the breather sleeve’s slots was a tiny slice, like a fingernail clipping of high-grade steel.

“Oh,” said Bruce, “I know what that is. It’s the circlip from the wristpin that broke loose, remember?”

Indeed I did. Eight or so years ago, when I was touring France on the bike, the front wristpin got loose and gouged a channel in the cylinder, so the bike and I went back to the airport in a rented truck.

Unlikely though this sounds, the only explanation is that the little clip somehow lodged in the crankcase all these years, until the teardown and highpressure cleaning somehow released it, kind of like a vintage Japanese horror movie. All that nice fresh oil swept the fragment into the pickup side of the oil pump, where street engines have a screen and racing engines don’t (yes, my XR engine has one now).

The bad news is that it stuck in the slot, stopping the engine and cracking the pump body. The good news is, this happened at idle, not 3000 rpm, so no other damage was done.

Bruce assembled a new pump, I put it all back in place, and all is well.

Time for philosophy: Vintage motorcycles are different, and it’s not just bodywork or electric legs. During its 25 years and 30,000 miles, my XR had a mainshaft come loose on the flywheel, a camshaft fell into the crankcase, a valve lifter broke in half, and we’ve already mentioned the errant wristpin and broken oil pump. Most different of all, the magneto drive came loose on the #2 camshaft, retarding the spark one degree per mile, and try troubleshooting that one.

Further, we’re talking street-tracker, meaning marginal lights, no weather protection, solo seat, kick or bump start, limited range, rough ride, handling at least as quick as your reflexes.

Why do this?

Because (this is my second rule of life) Everything is Worth What It Costs You, and the reward for the work and faith is equal to the investment.

My son John, who isn’t as keen on old bikes as I am, saw me putting the engine back in the frame for the third time and wondered, is this some manner of sign from Above?

Naw, I said, if God didn’t want us to ride old bikes, he wouldn’t have given us the cell phone.

Next Dam Ride is November 7, 2009; Hansen Dam off the 1-215. C U there.

View Full Issue

View Full Issue

More From This Issue

-

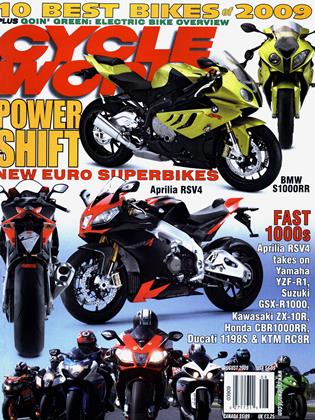

Up Front

Up FrontTen Rest, 2009

August 2009 By David Edwards -

Leanings

LeaningsA Guy of the Moment

August 2009 By Peter Egan -

TDC

TDCInstruments of Control

August 2009 By Kevin Cameron -

Departments

DepartmentsHotshots

August 2009 -

Roundup

RoundupElectric Arrival

August 2009 By Kevin Cameron -

Roundup

Roundup25 Years Ago August 1984

August 2009 By Paul Dean